-

Posts

158 -

Joined

-

Last visited

Posts posted by Robino Jones

-

-

18 minutes ago, Frank Wylie said:

Late to the game here, but thanks for posting this information!

I assume this is very valuable information when bi-packing elements in the projector head.

How did you determine the clamping pressure to be applied by the adjustment and is there a way to measure with a micrometer for repeatability?

Thanks again!

You could possibly hook a micrometer in the gate opening and place the tip on the cam but moving the cam block is not precise you have to wiggle it a bit to go up and down. My movement was pretty loose and you could visually see the issue by touching on a piece of film in the gate. I moved the cam in one little bit a time and tested until the film was held firm but not too firm. I have to say that after the adjustment was made, all my movements worked perfect in the projector even though I mentioned in previous post that the adjustment would work only with 1 movement..

It's been a couple years I'm a lot more comfortable with these things now, send me a PM maybe I can help you if you have a problem.

-

1

1

-

-

I went Thursday 5pm at the Landmark (old Sunset5) to see it on 70mm and after 4 seconds of during opening logo, the screen went black.. and then 4 seconds later it was orange yellow plastic melting with bubbles..the film literally burned on screen like in Gremlins 2! Never thought I'd see that - especially on 70mm it burned for a long time that a lot of plastic to go through! I left and got a refund. Last night went to Regency in Westwood and watched it on 70mm- I loved it. Will go see it again in Imax 70 at Chinese Theatre when it cools down - every screening for the next week are packed.

-

I heard that back in the heyday of optical compositing, Kodak would put aside the first batch of film coming off a newly aligned cutter/heart and it would be reserved for big shops like ILM. If anyone knows anything about this, please chime in; this is very interesting.

I really didn't know how complex it was to perf film, you can see in the video the first heart is for B&H perf and the second one (with the microscope, it's for Kodak standard (KS) - I wish they showed the 16mm and 8mm cutters too and elaborated on the alignment, how long before you need to re-align, are the punch becoming dull after a while? etc

-

1

1

-

-

On 5/28/2023 at 5:37 AM, Ludwig Hagelstein said:

Great test. How did you perceive perf stability?

You can see in the test side by side with the 5219 that the ORWO is really unstable. I was watching this video about how Kodak makes film, and you can see how complex and precise the "Hearts" are to perforate the film. Boggles the mind - I suspect ORWO may not have this level of precision, which results in stability issues. Fascinating stuff! Here's the video, I cued it at the perforation section.

-

1

1

-

-

You can get this little device:

https://www.catlabs.info/product/photoplug-optical-shutter-speed-testerI got one to figure out single frame exposure times for a very custom camera that has no manual ? I setup a small flashlight on a c-stand pointing at the lens mount, and then used the app to calculate the shutter speeds. It worked well and the film came back nicely exposed.

-

1

1

-

-

On 5/24/2023 at 7:37 PM, Dennis Toeppen said:

So EK is cheaper if you don't mind dust from DIY winding.

Unless you're a rookie, in a DIY shag-carpeted darkroom with feline assistants, or chain-smoking through your spooling session, dust shouldn't be an issue.

Also with that attitude you prob should go on craigslist you'll have more success with your sale ?-

1

1

-

2

2

-

-

On 5/2/2023 at 8:38 AM, Daniel D. Teoli Jr. said:

What is going on with the RobinoScan? I had never heard of it. Did you build it for yourself or to market the scanner?

I built it for myself, no plan for making commercial machines but may do one or two for close friends.

-

5 hours ago, John Rizzo said:

5244 is not release print stock, it is intermediate stock designed to make a Interpositive from the ocn or a internegative from a interpositive.

Thanks for pointing that out it's fixed now.

He mentions at 2.35min "You are viewing either a release print from 5244 EXR color intermediate film or direct video transfer from the camera negative” - I added the note at the beginning to make sure people knew which one they were watching.

-

Wanted to share this film I had in my collection. I never seen this one online anywhere and I'm sure a lot of you would love to view it.

The film is titled “Vision, the realization of your imagination” and was released around 1996 to introduce their new Vision motion picture color negative lineup. Narrated by John Sawyer, it demonstrates Vision 320T and 500T.The transfer was made on RobinoScan from a 5244 Color Intermediate release print. In one of the test they push the exposure -5 to +5 stops so the highlights are hard, but that's the way the print is and the transfer is not clipping.

I'm sure some of you saw this test film back in the day - would love to hear about it.

Enjoy!

-

3

3

-

-

7 hours ago, Robin Phillips said:

@Tyler Purcell I got my 2 cans yesterday, honestly Im unlikely to be able to do a real test as I'd hoped this month the way things are going. If you want 1 of my cans just DM me and I can send it to you if you wanna run an additional test at box speed so we can all see how it looks.

If Tyler is not going to take it I'll take it - @tyler's test was great but maybe a second opinion / different camera/scanner could be good ?

-

54 minutes ago, Robert Hart said:

Higher resolution scans will yield more detailed grain.

Film images are made of grains.

54 minutes ago, Robert Hart said:16mm film does not resolve much better than original interlaced standard definition television.

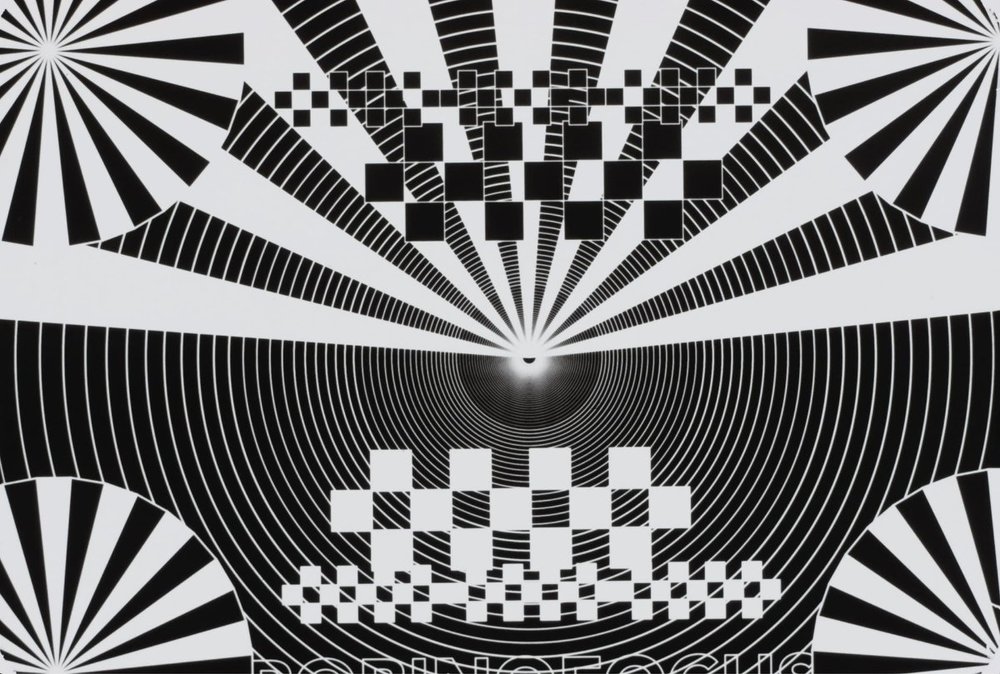

Here's a 16mm frame of a chart I made and scanned in 4K. (can't upload large files here so it is downscaled). I wish interlaced standard def looked like that back in the day ?

Not sure why I'm replying to this troll post but merry xmas everyone!

Edit: ..and this would look even sharper today on my new scanner..

-

1

1

-

1

1

-

-

16 minutes ago, Todd Ruel said:

Then he sends those digitized prints to me, and I do further cleanup with Dustbuster+.

I can't find pricing on Dustbuster+, may I ask how much the software cost?

-

I would have bought rolls for sure - it was a nice affordable alternative to Kodak but not anymore.

-

8 hours ago, Andrew Wise said:

I didn’t have any problems with scratching from my gate until about 6 months of use scanning a lot each week. I’d worn down the nickel coating on the gate, so I had to take it to a local shop to be plated. I decided to chrome plate it which was a bit difficult due to the increased thickness of the chrome, but it turned out fine.

That makes more sense. Was the scratching on the the perf areas or on the actual image?

-

51 minutes ago, Dan Baxter said:

even with commercial equipment the owner needs to properly test it with junk film before they use it with real film.

I built the machine, so of course I tested it with dummy film. lots and lots of them ?

53 minutes ago, Dan Baxter said:You have a gate that appears to have no warped-film clamp, whereas the ones I'm talking about are specifically for warped film so it will get warped film very flat without having to clamp up and down like previous commercial scanners did.

..but you haven't seen my gates Nostradamus, If you are referring to the Kinograph thread - everything on there is super old.

57 minutes ago, Dan Baxter said:you'd need to design your own if you wanted that ability.

Thanks very much I'm good ?

48 minutes ago, Dan Baxter said:Would your design work if the PTR rollers were removed and replaced with regular steel rollers?

Soon it will be only PTRs without the 2 metal tension rollers. Tension will be integrated in the main rollers. PTRs are designed to take out dirt particles not add them like the "friction rollers" example you linked to. My transport is like the Kinetta which is a great machine. Of course you need to keep the PTRs clean and give them little baths in soapy water from time to time.

I really didn't want to derail the thread with my machine, all I wanted was to share the stability I'm getting using perf sensor. I'm not comparing my scanner to anything, there's still so much to do on my machine - probably another full year of development and headaches. It's hard making scanners.

-

13 hours ago, Dan Baxter said:

I note you're running positives, negatives have a thinner base and are easier to damage if the tension isn't right or if there's imperfections in the gate.

The bottom rails are 3d printed and the edge guides are polished aluminum. There's also a spring loaded aluminum side pressure guide at the opening. The bottom rails are printed in the direction of the film and free of zits, there is no scratching. Obviously full metal would be very nice, but this works really nicely and require no maintenance beside a little dusting with a soft brush if needed.

The tension is monitored and adjusted in realtime via 2 rollers at feed and take up side. I haven't observed any differences in regards to the film transport between negatives and prints.

12 hours ago, Dan Baxter said:He can use them, and he does, but he wouldn't let someone else use them because they require maintenance and you need to test it with junk film regularly. That's why the polished steel is much better.

Most likely, it's just a bad design. My gates are very reliable.

13 hours ago, Dan Baxter said:Nice work on the fan, I believe I told you adding a fan should help reduce or completely eliminate heat-based sensor noise with that camera. You should turn the fan on the camera off and do a comparison scan to show what happens when the camera doesn't have that additional cooling.

Camera temps are 32~34c all the time, images are super clean.

14 hours ago, Dan Baxter said:You can't really compare your RobinoScan to any commercial scanner

I'm not, there's still a LOT of work to do on my machine. What I can say though is that my scanner does not scratch film and it's pretty stable.

45K for a film scanner that scratches film is unacceptable. I feel bad for Tyler having to build a new gate for his commercial scanner and having to figure out how to make it more stable.

14 hours ago, Dan Baxter said:it's designed to take small reels, it doesn't look like full 1200ft 35mm negs would fit, and certainly 2,000ft full print reels wouldn't either. It wouldn't be just about fitting them on but then doing the engineering work for tension control etc.

The design is ready for 2400' platters but I'm still using a prototyping frame. Swapping to larger platters takes 2 min with a screwdriver and approximately 20min to run the tuning/calibration motor sequence. The software and tension sensors do the rest.

I'm currently borrowing 1200' platters from an optical printer until the final frame is finished. I'll order laser cut 2400' platters in time.

------

-

12 minutes ago, Tyler Purcell said:

Heck if we ran the HDS at this slow of a capture speed, you'd never see the perfs being unstable.

I can do real-time. Scanner was set to 12fps when I took the video. Here's faster.

16 minutes ago, Tyler Purcell said:The scratching is unacceptable. It took us quite a bit of work to get it NOT to scratch. Polishing, machining, re-polishing, etc. We finally got it, but the fact the first roll we put on it, got damaged, scary. The good new is, the older gate, which they were very happy to help us acquire, does not damage film period. It's just less stable, so we had to make some changes to make it stable. So now it's a lot more stable. Is it pin registered? No way. But it's fine for 16mm.

Sounds like a nightmare, how much did you pay for this?

16 minutes ago, Tyler Purcell said:I'd love to see this in 16mm.

Maybe when I swap the gate I'll post a video.

-

My scanner (RobinoScan) uses a perf laser sensor and stability is good on both 16/35. There are some micro bumps at splices, but nothing too bad. You won't even notice splice bumps if the splice is clean. In general with fresh film it's pretty much rock solid.

I do stabilize in post right now, mostly because of splices and old warped films - have to do this until I the final capture software is done (using openCV) but in general, it's very stable.

It's crazy to me that the FilmFabriek HDS+ is so unstable and scratches film out of the box (according to Tyler Purcell). Sounds like a terrible scanner to own.

Here is my scanner stability at capture, without any post-stabilization. Please excuse the crooked framing as the camera is unscrewed from the mount at the moment.

-

3 hours ago, Tyler Purcell said:

We just printed our prototype fix last night, the scanner is now stable enough for me to be satisfied. My "guess" was accurate. The capstan is not round, thus the film warps slightly and just enough to make it unstable. Our fix, seems to solve this problem. Now we can integrate it into the gate, which should solve all the problems. It'll take a hot minute, but hopefully spring time, we'll have a new gate which solves all these issues.

Can you post pictures of your modified gate?

-

1

1

-

-

Beautiful! - I love the look of Ektachrome. Makes me want to go canoeing ?

Also wanted to thank you for recommending thenegative.space, you saved me a LOT of money and I can't recommend their service enough. Super efficient and pro - I'll be recommending their service from now on.

-

On 11/17/2021 at 5:07 PM, Karim D. Ghantous said:

The whole of Eyes Wide Shut was shot with a two stop push, and that was on 5298.

Grainiest film I ever seen. But I love it.

-

1

1

-

-

On 10/21/2022 at 7:19 PM, Larry Baum said:

I dunno, I wish I was wrong, but it is starting to seem like I was likely correct.

Can you post examples? And if you don't have any examples on hand, shoot some film and have it scanned by Robert on his Xena and LG - a third scanner like the Scanity HDR would be helpful as well for comparing the results. Share your tests here so we can look into what you're talking about.

There might be a simpler reason why LG is not getting back to you. You might "feel" that you are correct but without anything to back it up it's not worth much.

Edit: Also get a DSLR scan of the same film, you said they had wider color gamut.

-

1 hour ago, Perry Paolantonio said:

It's barium sulfate mixed with acrylic white paint. It's basically harmless. You can buy it at Amazon, in fact.

Heres the MSDS for barium sulfate.

Exactly.

It's also used in medicine as a radiographic contrast agent. Mixed in water, patient drinks the mixture and it helps the contrast on Xrays in the GI tract.

https://www.mayoclinic.org/drugs-supplements/barium-sulfate-oral-route/side-effects/drg-20062255?p=1

-

Video Assist Sony xc 999 Wiring Question

in 35mm

Posted

You have pin 3 and 4 inverted. The correct pinout is as follow:

pin 1 : - GND

pin2 : +12VDC

pin3 : Video GND

pin 4 : Video Out

pin11: +12VDC