Joseph Tese

Premium Member-

Posts

132 -

Joined

-

Last visited

Everything posted by Joseph Tese

-

Light Rotating around An Individual.

Joseph Tese replied to Nelson JJ Flores's topic in Lighting for Film & Video

Just the casters might not guarantee a smooth swivel, so they make heavy duty lazy Susan type bearings for the center point (talent) then have swivel casters on the sides to help stabilize and support. -

Light Rotating around An Individual.

Joseph Tese replied to Nelson JJ Flores's topic in Lighting for Film & Video

What is the distance from camera to the farthest light ? (The one directly behind talent). Is it close enough where you could safely menace/boom ? If the menace base is right behind camera, then it won’t have consistent fall off and intensity (weaker and flatter on sides than behind talent) because of varying closeness. Does the fixture have to be directional, or do you care if it’s an Omni/lantern type light? - If its okay to spill it away from talent, then you don’t have to worry about panning the fixture as it swings. Is the background black? Any set elements? If just the subject, swivel the chair! If table involved, you can build a sturdy platform with 2x4s and plywood, and by having fixed casters the same distance from a center point (talent), it won’t sway when rotating. -

Beautiful! Would love to see a breakdown of any of your lighting set-ups. Did I see a brute practical in the train scene for the rejoice ad?

-

Hey JD, there’s no 60amp feeder. Where do you see that? In this scenario, it could only be powered by two phases, and by a 50amp (125/250) plug. Each hot is split and a 100amp Bates connector is put on. The connector accepts the 50amp gauge safely. This works fine, but just needs to be clear and heavily labeled so no one gets the wrong idea, as Ed pointed out.. it’s 50amps per line not 100. To me, this set up just felt a little sloppy, and is my last resort whenever I have to pull power from a 50amp twistlock, and wanted to hears other’s thoughts. So in scenarios I can’t do much where I just need one high-wattage light, and the rest are leds (which happens often) are there actual negatives to pulling from one leg?

-

Agreed, It seems like some are and some not, depending on material. Polyester is questionable, but if it's Nylon it is most probably flame-retardant. As you said though, always verify prior to purchasing instead of assuming.

-

Thanks, Phil! I didn't realize Tulle was the same thing. That search alone, yields much more results for a DIY application.

-

Thank you. Didn’t see this one.

-

I read the following thread, which was helpful to a degree. Perhaps an in-depth degree. But I still have some questions, as it seemed to just briefly touch on it. Why is it important to balance the load when plugged into a three-phase building? In my case, we have a company switch tied into a three-pole 100Amp breaker. Does everyone agree I should keep it within 20% difference between phases? Prior to this question, I thought this applied only to gennies, but I thought differently after seeing this video Granted, it's in 240v land - but will the same affect result here if unbalanced to that degree? I've never heard of that happening to a cable. What do you do if you have to run just a 5k on one hot, and the rest of the lights are LEDs.... Obviously imbalanced, so do I have to source and burn higher-wattage ghosts on the other phases to be safe and proper? If a shoot just lasts a day or two - Doable? Is this detrimental to the cable, distro, and anything within the building power? Also, concerning the neutral taking the difference between hots: Does this apply only to single phase situations, or three phase as well? Eg, if I run 50AMPS on one hot, and nothing on the other two, can I expect 50AMPs on my neutral? This may tie into my previous question, but in situations where my neutral is carrying a load, how/why is this bad? or is it not? On a sort of similar note - Here's a pic of a two-fer I had made up. It's so I can use a 100AMP lunchboxes on a 50 AMP CS 6364 (125/250v) connection. It splits each hot to get dedicated 120v. Obviously, I'm limited by 50AMPS on each line, and not 100AMPS. 1) Are there any concerns about this? To my understanding, it's the exact same practice as a consumer Generator Y-Splitter from homedepot 2) When using this two-fer in a 3-phase building, does it treat unbalanced loads differently if used in a single phase?

-

I think that will increase the moire'. I was trying to see if there was a cheaper alternative.

-

Hello, Has anyone found material that would be comparable to double bobbinet rags? My fabric store search wasn’t successful. Then there’s the issue of side stitching so it doesn’t tear? For smaller or custom applications not involving a frame maybe this would be useful to know.

-

Light panel and diffusion frame on same stand

Joseph Tese replied to Stephen Lewis's topic in Lighting for Film & Video

Grip helper? https://products.msegrip.com/products/grip-helper I think there’s baby ones, too. -

Grip Truck - Liftgate Recommendations..

Joseph Tese replied to Joseph Tese's topic in Grip & Rigging

-

Grip Truck - Liftgate Recommendations..

Joseph Tese replied to Joseph Tese's topic in Grip & Rigging

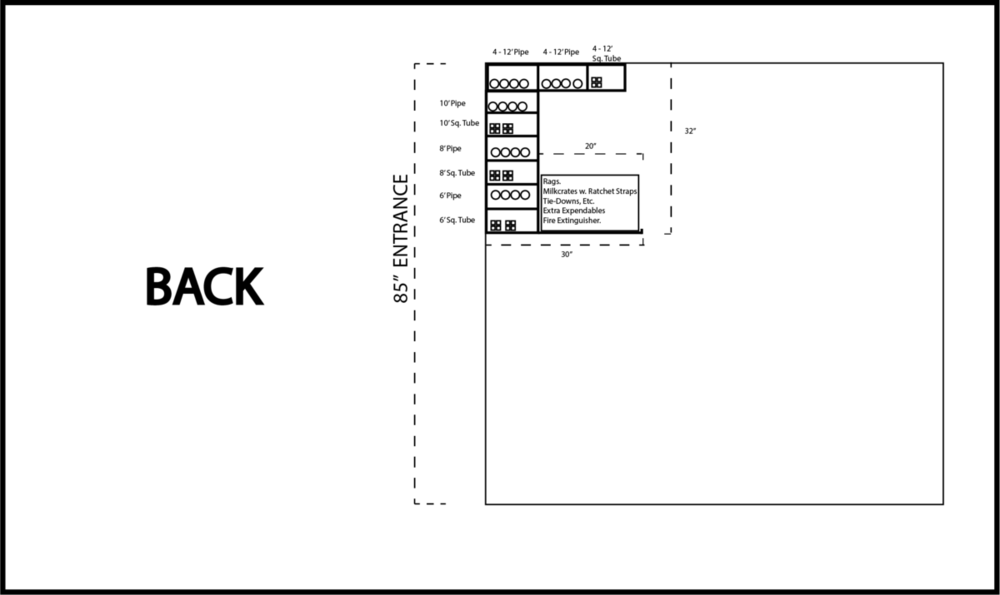

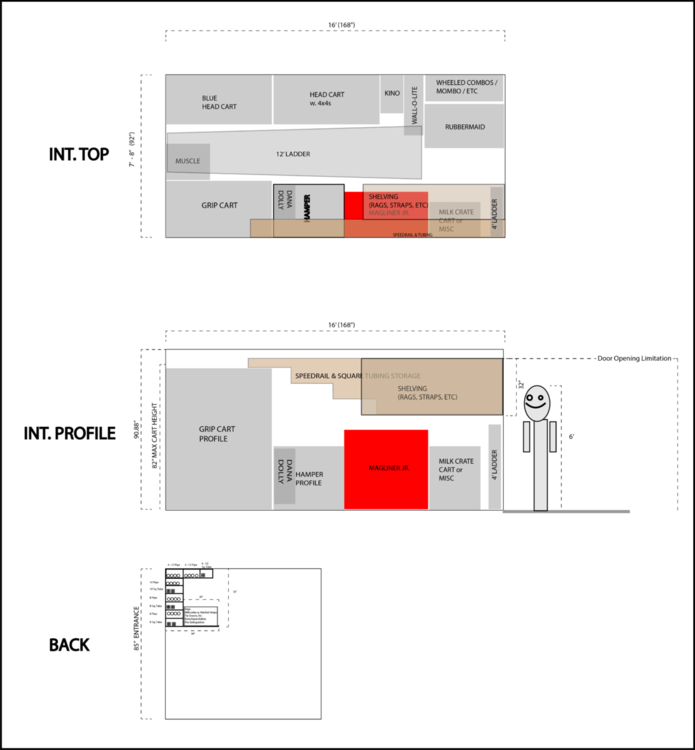

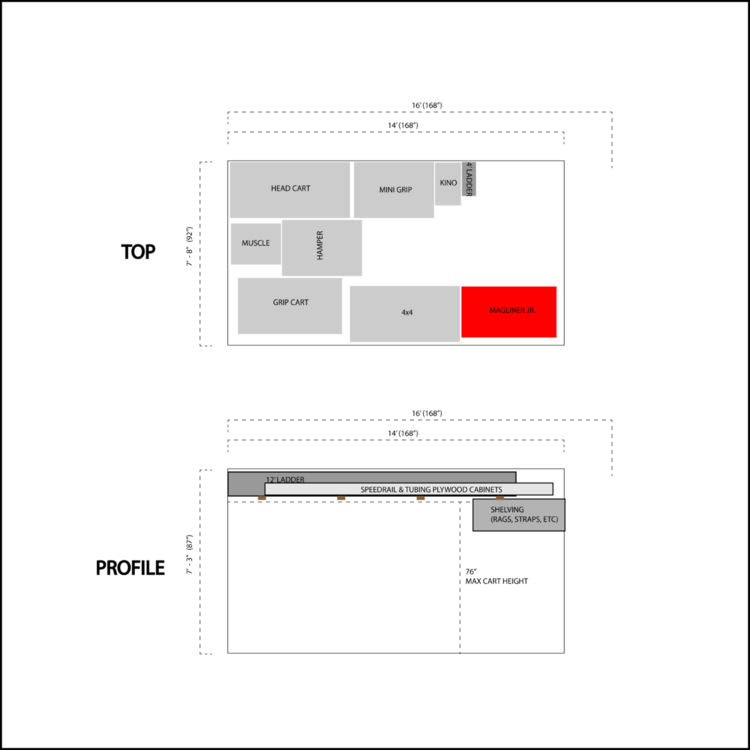

Thought I'd update in case anyone was interested in a more detailed drawing of the planned layout. Wouldn't mind if anyone chimed in with feedback or suggestions. See attached .png -

Help with lighting white cyc.

Joseph Tese replied to Cameron McAlpine's topic in Lighting for Film & Video

Do you have a height limitation? What's your ceiling look like? If you're limited on height like we are, we found that a ladder light system is incredibly useful, and also incredibly soft due to its large source. See pic: Please ignore the temporary rigging and droop effect. This was taken mid set up and unfortunately don't have a pic of it final. This works for a very high key look, with other fixtures on the ground to help shape the talent. This also has helped eliminate the annoying shadows on the ground if doing anything full body. It would also require either cyc lights or something like 4 bank kinos/leds to bring the wall up, and just play with the ratios. Again, if you're limited on height, then the cyc lights have to be placed further back to reduce fall-off. -

I bought a pelican rifle case for ours. Obviously not a soft case, but works. How many are you wanting to store? I'm assuming it's the t12 size. On the same vain, here's a soft rifle case that comes in 51" lengths. Don't know if the shoulder straps would become a nuisance. Maybe the extra compartments would be handy for accessories, if applicable. https://www.amazon.com/Savior-Equipment-Warfare-Tactical-Backpack/dp/B07QLBPZ1L/ref=sr_1_11?keywords=long%2Bsoft%2Brifle%2Bcase&qid=1566224290&s=gateway&sr=8-11&th=1&psc=1 Ahh.. Realized you said "tube". I would second Stuart, but also assuming you have a 4' tube? So maybe a longer version like this: https://www.amazon.com/Adir-641-Telescoping-Document-Resistant/dp/B00AFXINTM/ref=sr_1_24?keywords=long+tube+case&qid=1566224575&s=gateway&sr=8-24 I would get OCD about it banging around in there. If you can access both ends, which it seems like you can, Maybe cut out a circular piece of foam and epoxy it to the inside for the entrance and end?

-

I'm curious why no one mentioned the Litepanels Gemini? Too pricey? I'd say it's way more manageable than the S60.. I'm also surprised to see its current retail price. I feel like it was available for high 3s, low 4s USD at one point.

-

"Beauty Light" Recommendations w. Parabolic?

Joseph Tese posted a topic in Lighting for Film & Video

We might get a Joker 800 soon (Took long enough!) Been digging the look of a parabolic, and would like to have that option with the J800. What has been your success with the Joker 800/ Parabolic combo? Are the k5600 Kurves my only option? Any other reflector recommendations? Would like to know what other continuous light sources are commonly put into parabolics as well. -

Compared to your original alternative, and as already mentioned, the Modern slider (010-2050) is very short and probably meant for a single piece to go through it, not two pieces. Wouldn't feel good about that at all. Even though the longer Modern (010-2029) has more set screws, the length is what's going to make it a safer and more stable option.

-

Grip Truck - Liftgate Recommendations..

Joseph Tese replied to Joseph Tese's topic in Grip & Rigging

Definitely going with Palfinger ILM, 2500, single piece (not split) gate. Would be nice to have a cantilever style but, you know, money. Did a lot of research with comparable models between the "three" leading brands, if anyone needs to know. Pretty sure our payload would be appropriate for Class 4. -

Grip Truck - Liftgate Recommendations..

Joseph Tese replied to Joseph Tese's topic in Grip & Rigging

Ed, A mostly aluminum gate build should live between 700-1000lbs. Once I confirm model, I'll keep that in mind. Called Morgan, and said that a 16' box can be between 3,500-4,000 lbs. Of course a little less for 14'. Figure 5,000 LBS for the Box & Gate to be on the safe side.. My guess at calculating the actual load would be dodgy at best...Maybe 4,500lbs? -

Grip Truck - Liftgate Recommendations..

Joseph Tese replied to Joseph Tese's topic in Grip & Rigging

I'm all for making stuff, and make attempts myself when I can. Would absolutely love to see what you have, especially if it makes it easier for a local source to replicate.. -

Grip Truck - Liftgate Recommendations..

Joseph Tese replied to Joseph Tese's topic in Grip & Rigging

Can you guys also speak to truck class ratings for this set-up and weight? Class 4 NPR's are the most common in this size. (14-16ft) But can a Class 3 Box do it as well? Any recommendations on the box layout / installs (Such as caibnetry, etc)? -

Grip Truck - Liftgate Recommendations..

Joseph Tese replied to Joseph Tese's topic in Grip & Rigging

I wish I could find used carts on CL where I live.. -

Grip Truck - Liftgate Recommendations..

Joseph Tese replied to Joseph Tese's topic in Grip & Rigging

Looking at the ILM 72" depth. The ILK seems like it would have larger install costs, but will look into those as well. We will see how the quotes stack up. Spoke to rep, the ILK requires a higher bed height (ground clearence from ground to bed floor). Also the ILK might blow the budget. We're also switching to a cuter, 14' box, probably 94". The rep says an ILM Railgate Style will accommodate the whole width. He says the terminology on the website (Looks like it's all 88" for ILM models) is not accurate? Don't know what the deal is there, but will find out. With these factors, I feel like the ILM will probably be the cost effective option for our size box and application. Here's a rough outline of carts. 92" worst case scenario. Ed, do you have an opinion on Backstage vs Studiocarts?