Search the Community

Showing results for tags 'damage'.

-

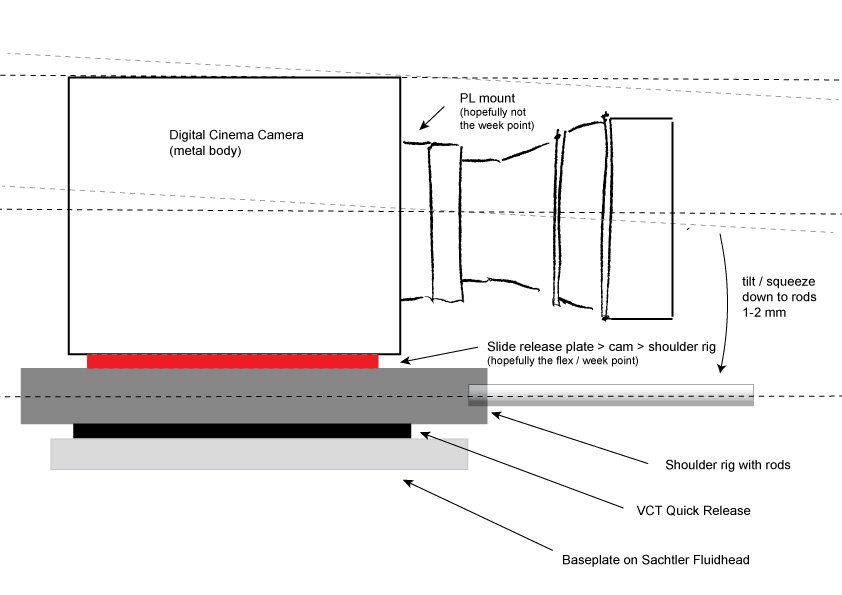

The wireless lens control system used here comes with a very strong default torque, causing a strong pressure from top down on a robust lens when hitting the end point of the lens focus spin, if the calibration has failed or has been accidently changed or reset. I watched with eagle eye how the whole camera body horizon including the lens dipped down on the front side coming minimally closer to the rods, mounted on a shoulder rig and slipped into a VCT plate on a Sachtler fluid head and tripod. I was shocked about this situation, asking myself if there is any hidden damage on the body or the PL-mount or the lens now possible. Since this is an expensive robust cine lens, I do not worry about the lens focus ring that much. But exactly this sturdiness has caused the body-lens axis to come down based on the lens control motorized cogwheel trying to spin ahead. And even serious professional digital cinema bodies come in various levels of robustness and I think/worry about which week point could have been stressed here (and I hope for the baseplate / shoulder-plate connection, not for the bottom of the body or even worse, the PL mount lens connection). I deeply hope that this had no effect on the PL-mount, or the mount-sensor construction, nor on the metal body of the professional digital cinema camera itself and that this small movement is maybe acceptable(?) in terms of baseplate flexibility or the whole rig. Thus my question since I never had such scenario to compare to before. I would love to hear from some long year experienced DPs or Ass. that this minimal dipping is not such a dangerous thing like I think it is, at the moment. Maybe a dip of one or two millimeters, on a lever length of 200-300mm (body + lens) all together. But you can see it when you concentrate your eye on the horizon of the body-lens level in comparison to the rods below and the background behind. The rods stay horizontal while the body-lens axis comes down forced by the pressure of the lens control cogwheel on the lens. Additionally, I wonder if the motorized lens control system cogwheel was always that noisy before, or if it has been damaged by this little event from before? Can anyone share experiences with such situations? I doubt that this is a rare case since such systems often "forget" their calibration end points. All I wonder is, why the torque was so strong that it was able to dip/squeeze the body-lens axis down closer to the rods a little bit. (Torque was 50%). I carefully tried to check the flexibility of the baseplate shoulder-plate connection, but I am not able to reproduce this dipping, so the torque must have been quite strong to create this dipping. I did a sketch of the whole thing to illustrate it better.