Search the Community

Showing results for tags 'mc17'.

-

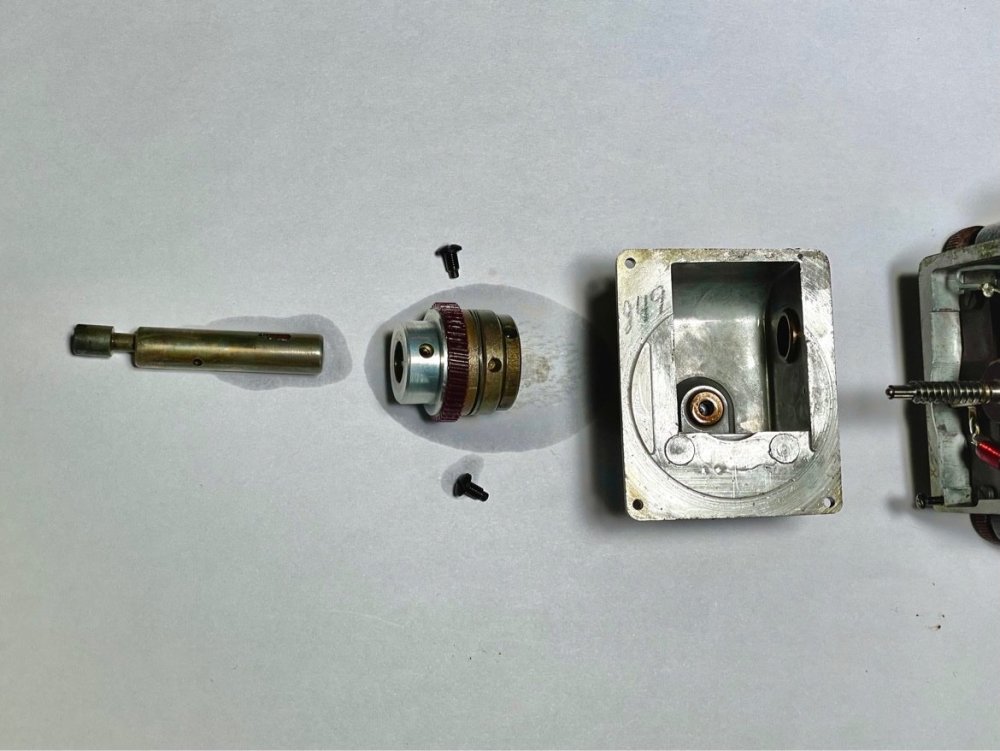

I thought I’d better start a new thread with this, as it’s tangential to the thread it was originally added to: I believe this is an MC-17b motor. I bought it without cables or other accessories in as-is condition. Getting it to run was not difficult, but it was showing signs of corrosion on the fixing bolts so I thought I’d have a peek inside. After dismantling and cleaning I set out to discover how it was meant to work—particularly the “friction drive” mechanism I’d seen mentioned in several related online texts. What I’d originally thought was a clutch/friction mechanism (photo centre) turned out to be something more like a shock absorber made up of several wavy washers and tensioner rings, all pinned to the main gear—which was initially seized onto the outer shaft by corrosion. I’ve studied the manual (which by the way states the motor runs on ball bearings—there are none), and I’m still no closer to understanding what constitutes the friction drive, and how it’s supposed to work. The manual describes mechanical operation: Pressing the motor lever fully home when the motor is not connected to the camera results in the motor running continuously with the drive shaft engaged. When connected to the camera this would mean the camera drive shaft would also be rotating continuously. Is this what’s meant to happen? With the drive motor attached and running, and the camera lever at the “O” position (motor disengaged), is the camera in effect “idling” until the front or side shutter release is engaged? Is this also why the manual advises the motor should not be left on in this state for more than 15minutes (wear on the camera mechanism)? Thank you for reading this far, I’m aware that my assumptions may all be incorrect, in which case I’m happy to be corrected.