-

Posts

301 -

Joined

-

Last visited

Posts posted by Gareth Blackstock

-

-

So recently I bought a Pentaflex 16mm camera, exactly the same, apart from cosmetics, as the Pentacon AK16, and as per the advertisement, it was not working and in need of repair. When I opened it up, it had what appears to be a very common ailment of Pentaflex 16mm cameras. One of its Bakelite cogs had lost some teeth and therefore a side or bottom mounted motor would not be able to drive the camera. It seems that when people who do not know the camera try to manually get it to "turn over" or actuate the movements to see the mirror move, they fail to unlock the drive and inadvertently break off a few Bakelite cog teeth.

So, I contacted a person with a 3D printer, sent them a could condition cog to copy, and they were able to print off lots of cogs for a fee. I re-installed the plastic cog into the camera and it works very well. The repair is pretty straight forward, no electrics, no calibration, and a touch of lubrication. I am pretty impressed with what a 3D printer can print, I imagine there are lots of little bits and pieces from old cameras that have since broken and essentially killed the camera as spare parts are non-existent. 3D printed parts might be a good lifeline for fixing old cameras.

I used Envision Engineering of Queensland, Australia WEBSITE LINK

Below is a link to the cog repair details on my website:

https://canon-s8-repair.yolasite.com/pentaflex-16.php (at the bottom of the page)

The below image shows the printed black cog, the dark brown Bakelite original, and a broken cog mounted on its metal spindle.

-

1

1

-

-

Thanks for the feedback, it was certainly an awesome moment... like that scene from Frankenstein..."It's Alive! It's Alive! It's Alive! It's Alive!..etc etc" you get the idea.

Thanks also Robert, I figure you're pretty busy... all info is good info right now, lots of gaps in my knowledge of this machine.

Gareth

-

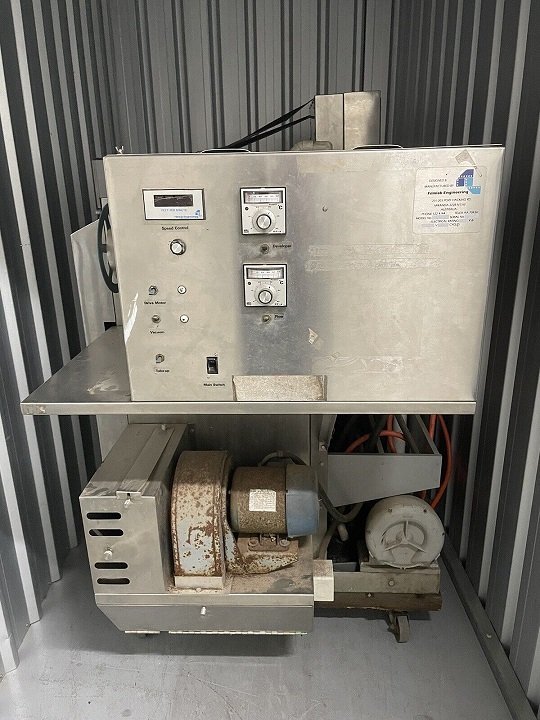

So a quick update: With advice from an electrician I have wired the processor to run on 240 volts house power, however I have disconnected the two 3 phase motors and heaters, just so I can see if the machine is actually functioning.

Well the processor fired up and works very well. I filled the vats with water to help clean and assist with the processor, I figured that as all the rollers are dirty, the built up grime may slow the machine somewhat. I had to manually assist the clear film carrier travel through the vats, obviously some of the rubber rollers need a clean to better grip the film carrier spools that convey the film. The film feed roll system and tension release works well, the take up roller and tension adjust works well, the vat temp gauges work... I could not start the pumps, I am thinking they might be linked to the circuits I disabled.

Next step the electrician will hopefully wire up the VFD I bought (converts single phase house power to 3 phase to run such machines) I next lift out the roller assemblies for a wash and fault check and power wash the vats.

Once thats all finished I hope to get the machine running, write down the various settings, time how long it takes for film to enter and exit to calculate what speed to run the processor on to properly fix and develop film, install stainless steel sealed tubes to reduce the amount of chemical I will need..... and then run of and shoot heaps of expired stock (of which I have loads) and practice not buggering it all up.

Below are links to short clips of the machine rollers turning.

https://youtube.com/shorts/NMHw8LrqKoE?feature=share

-

1

1

-

2

2

-

-

What about an Auricon chop top? They run as quietly as a CP16, variety of ways to run one on a battery, or power point, 400 ft loads... and there are more on ebay than CP16's.. but heavy....really heavy... and a dog leg viewfinder...

-

Hello,

Thanks for the support, i like a challenge... and it occured to me that if i ever get around to shooting my stock of expired film and processing it to b&w... without sending to the U.K or U.S, then id better buy my own processor.... or pay $$$$$$ sending it overseas.

Future proofing i guess...

-

And these two large pumps to filter the developer and wash could perhaps not be used until after the processing is finished, further reducing the power draw.

I will have to draw myself lots of pictures and diagrams to find my way through which does what.... and what items can be switched independently. I like a challenge!

-

1

1

-

-

I also took the opportunity to look over the mechanicals.... as I was worried about the 3 phase requirements. Looking at all the motors and pumps, it is only one motor that is 3 phase, the dryer motor (blows hot air into the drying cabinet)

All the other electricals are single phase, or can run off house power. So if I remove the drying motor, and use a 3 phase converter... then I may be able to run it without blowing fuses.

-

1

1

-

-

So, a quick update on my adventure to get hold of this machine.... I returned to pick it up with a hire ute and a trailer used for bobcat diggers... and using a 2 tonne block and tackle, boat winch, crow bars, ramps, ratchet straps et all...... we finally got the bugger onto the trailer. Getting it home and unloading it alone, my helper abandoned ship early, probably pulled a muscle.... all went well. I threw together this funny little video taken from my security camera. And yes, it is now inside a shed, nice and dry. I needn't lock it away, its not as though anyone can steal it...

-

1

1

-

1

1

-

-

Whoa there..... im not keen on getting into film processing as a business.... in Australia i reckon that would be a very good way of throwing money away.... in a big hurry!

Mostly i was keen as it is thr last machine of its type left running ish in Aussie.... and i do like to tinker.... im not overly phased by the power draw, 3 phase motors can be replaced with modern higher torque single phase motors.... and i looked at the specs Mark linked to, thats a 20 foot processor! Im guessing the one above draws less....

G

-

1

1

-

-

I had a quick conversation with an electrician regarding 3 phase converters, he said that while a converter would likely get a 3 phase machine running, once the machine started drawing big power the converter would fail. And getting 3 phase connected.... thousands. Sadly i do not think 16mm shooting and processing in Australia will last much longer... enthusiasts on the ground are dwindling. And with a kid, house repairs, and a full-time job... i dont get time to shoot film, let alone start a business developing film.

Sigh....

-

Well sadly I have not collected the processor.... I went to collect it with a trailer and some heavy duty winches.... but when I got to look at it, the machine was a monster!.... the photos were of one end, not the most of it as I thought. By my estimation it weighed in around 500 kilos, half a ton. My little 6"4 trailer would have crumpled, if I could have moved the monster onto it!

So it would essentially need a car trailer, several winches, strong ramps, and a powerful car to tow it 300kms back to my house.... and I discovered it needed 3 phase power to run...... So I bowed out, thanked the owner who was very understanding.... and went home. I did find out that the film dryer is included within the beast, so the processor is truly all-in-one.

The owner is putting it up again on ebay in a desperate bid to almost give it away to someone who will use it.... Does anyone here live nearby who wants it?

Maybe I should start a Go Fund Me site?

Gareth

-

Gday, thats a pretty cool idea... i will try that. Usually i have timed shutters by marking film, slowly feeding it through the gate, and examining carefully thr position of the shutter.... but i definetly will try that app.

Thanks, Gareth

-

Wow, there is some really good info here. I looked around the net to see if there was some footage that had been transferred with one, nothing came up. The owner states that it works well, but at USD$370 it is a fair amount of money. It is RCA output and a PAL system. I thought it would be handy, and I already use a projector for viewing, and sometimes I use an old mini dv camera to record "off the wall"

And I guess at the end of the day it's a fair amount of money for very obsolete equipment that if it gets quirky it will be impossible to repair... I'll ask if the guy will take a $100...

Thanks for the advice everyone, I think I'll avoid this one...

Thanks, Gareth

-

Hello,

A long time ago I bought an Auricon quite cheaply, non running with no power cable, just lots of bits and pieces. I finally got around to buying a 120 volt inverter to get it running. After a bit of research i discovered mine was a "chop top" -a common upgrade in the day.

Mostly I started taking the camera apart to find the correct wiring so I did not cook anything, yet it came apart surprisingly well, and I was impressed with the good design and seemingly ease of maintenance. So I kept taking things apart.... I added lots of pics to my website, hopefully if future enthusiasts buy an Auricon the pics will help get their camera running again.

https://canon-s8-repair.yolasite.com/auricon-cm72-a.php

And yes, the camera is running very well, still a little noisy, but good to go. Just gotta time the shutter... there's got to be an easy way...

Cheers, Gareth

-

-

Hello,

Recently one of the above has been listed for sale, apparently in good order for around USD$370. I did some quick research, 410,000 pixels or around 450 lines of resolution. Now I realise that the resolution is woefully inadequate compared to modern scanners... However, could it be suitable for small screens? Would this type of scanner offer good results for small screens, computer screens for instance? Say 20 inch maximum?

I watch a youtube video of a guy saving the scanned footage directly onto a laptop and saving it as Mpg-4. A pretty handy feature. As I have no intention of displaying on a large screen what I shoot, mostly its camera and footage testing15f_2920_Cabrio_a2_resized_y.pdf , I am curious if a scanner like this could suit my needs.

I have attached an article on the TRV below.

Any thoughts?

-

Hello,

I will be picking it up on the weekend, i cannot wait to get a closer look. Hopefully it is complete, i am not averse to modifying or adapting parts from other machines to keep things going. I imagine parts for these are nonexistent.

I will certainly be in touch once i get inside it, lots of pics i shall take!

-

Hello,

Well im not sure about processing more than a couple of experiments to see if i can run it correctly. There are no manuals for it anywhere, most labs probably threw them out once they learnt how to run it... i will have to learn a bit. Also, Mark, i was curious about tanks, however looking at the plumbing out the back i am hoping the tanks are small and inside....

I will have lots of fun i think....

-

1

1

-

-

-

So a quick update.... I am now the owner of a B&W processing machine... 16mm and 35mm.... I saw it come up again on ebay, and contacted the seller. He told me the new owners were unable to collect it. Apparently it weighs a ton.. So it was basically me or the scrap metal merchant. It is Filmlab Engineering machine, very well built, high quality, Australian made, and after I spoke with the now closed company's old head accountant, it is worth a fortune in high grade stainless steel alone.

So I will get it running, and hopefully with help from members here, experiment with chemistry, timing, trial and error until I can state it is back in running condition. I have hundreds of feet of old Ektachrome 7240 news stock I can practice on... I am hoping that when I get into the guts of the machine I may be able to reduce the tank capacities, (without reducing length?) so less chemical can be used at a time. I have no idea how many litres are needed for how much footage etc.

I am sort of excited, it will annoy my wife no end.... I might call it an Eastern European dishwasher to throw her off.. she's sort of used to 16mm camera parts lying around the house...

Cheers, Gareth

-

1

1

-

1

1

-

-

Well I reckon that on the face of it, its seems a reasonable idea, considering Putin's long history of sharing many traditional dictators traits.... however, I disagree on changing the name of this forum.

Firstly, for some reason this forum is the only one named after a culture, Russian that is. All the other sections are by manufacturer. Odd. Perhaps the forum should have been named Kinor/krasnogorsk/kiev/ et all... but that would not have been a good choice, not enough users of each brand to justify it. So Russian gear it was it seems.

Secondly, Russian gear, as it appears to me, loosely represents all the film equipment manufactured within Russia, either before or after the USSR fell. And includes all the equipment made before the revolution of 1918 (not much used in Russia was made there anyway) And in my mind, if the forum is going to be named after a culture, and not a manufacturer, I think even Russian's would prefer it remained Russian gear and not Soviet gear. Then you would be labelling an entire industry after a political regime.

For example, imagine the 16mm forums were named after cultures instead of manufacturer, you could have American, European, British, and Russian gear. Not a bad idea perhaps, now changin the Russian gear forum's name to Soviet gear because of putin would be like changing American gear to Mc Carthism gear, or Bush era gear because Trump gets elected. British post-war gear could be created from European gear because of brexit, etc.

I imagine many people within an industry would prefer not to be labelled as per the political regime of their time. And I doubt many Russian's employed in the film equipment industries would like their equipment being denoted as Soviet.

Putin hardly represents Russian culture, and i hope that when he is gone, normal everyday Russian's won't have to bear the inevitable collective guilt of their country's leader being responsible for throwing the world into turbulence.

I think the loose term Russian gear fits well over the enormous amount and variety of equipment manufactured over God knows how many areas and regions within the Russian borders over the last hundred years. And I think changing the forums name would mean all the old posts might get deleted....

Gareth

-

Thanks for the really helpful replies, so i lost the bid, perhaps If I had bid more the machine would have gone for a great deal more.. its hard to tell how much another person wants it. I actually intended on getting it up and running, servicing it, running some film through it, then donating it one of the small home labs in Melbourne... I enjoy mechanical challenges, and I understood pretty well running the machine would probably cost more than I could justify as I do not shoot much film these days.

I saw recently a giant colour negative processing machine from Filmlab Engineering recently sold for under $100 in canberrra, the guy I spoke with told me such large machines used to sell for around 1.2 million.... I did'nt have the heart to tell him one sold for less than scrap value. He seemed saddened by the companies demise, he told me he was the last person employed, and it was his job to donate anything of value, scrap the rest, and bin anything else.... machine blue prints, intellectual property etc etc.

These stories I find interesting, we all remember Kodak's demise and struggle to remain afloat.... but the hundreds of stories from people who witnessed items being scrapped when just months earlier the items were highly prized. Imagine how many machines from the processing industry have been disposed, sold for scrap, accessories and people with years of knowledge laid off... obsolescence can be cruel..

This is the one i went for...

https://www.ebay.com.au/itm/284961827189#vi__app-cvip-panel

The below link was for thr very big processor...

-

Hello,

I recently saw a black and white 16mm and 35mm cine film processing machine come up on an auction site.... and although I do have heaps of film ready to shoot, and eventually process... and i love a tinker project... is it worth getting one's own processing machine.... even if just for consistancy of results over home processing?

It is starting really cheap.... but i am nervous about buying a machine that may require specialist adjustment or at least a manual.... does anyone have experience with these machines?

Gareth (in Australia)

-

Hello,

Yeah, my CP is a project in waiting.... when I first got it I treated the circuitry with Inox protector to try and slow future oxidisation, and also wiping down the interior magnesium with Inox to try and prevent oxidisation buildup. I have found on an auction site 20 volt rechargeable batteries for power tools, I suspect the amp might be too high.

https://www.ebay.com.au/itm/384820897329

https://www.ebay.com.au/itm/224109974939

You can also get on the same site adaptors to take the battery and you can hard wire the adaptor into the camera, thereby just clicking the battery into place, just like a powertool attachment. I am pretty keen to try it out...

.jpg.42f660a670f0f26736406e04a5973355.jpg)

Pentaflex 16mm cog repair

in 16mm

Posted

This picture shows a mock-up of how the cogs sit on the camera body and their relation to each other