-

Posts

2,364 -

Joined

-

Last visited

Posts posted by Robert Houllahan

-

-

-

2 minutes ago, Tyler Purcell said:

Did Renny make those, or was that home made?

What do you mean "Home Made" ?

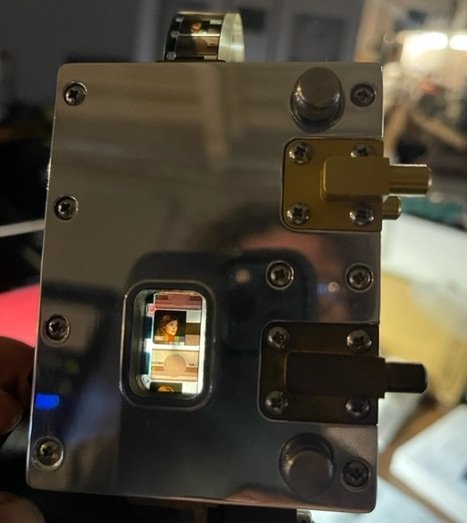

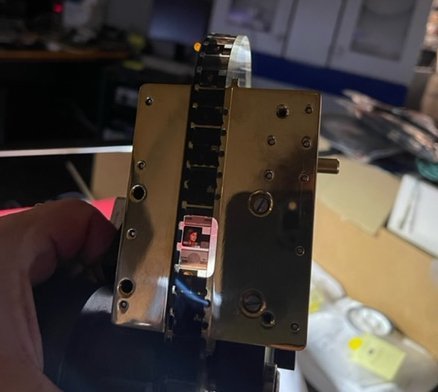

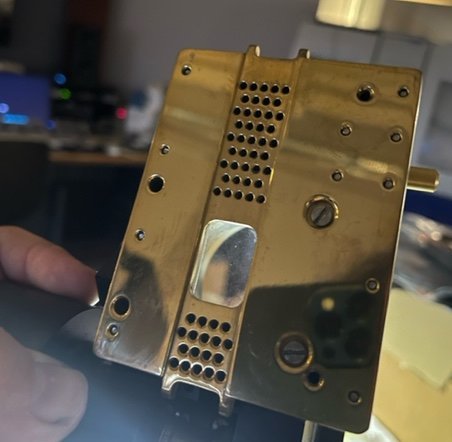

Rennie designed them and they were fabricated with CNC mills out of brass and stainless steel etc. They have a very large flow turnover and the quartz apertures are distanced to make spots etc out of the focus plane, they do not look very different than the Arri liquid gates for the XT they are very costly to build.

-

In response to the OP's question about scanning rates, as others have said the more pixels and DR the more money you have to spend, in a log ca$h curve ;-).

A Scan Station 6.5K in 6.5K mode and HDR runs at 7.5FPS (Same speed as a Spirit 4K) and I think it can go 60FPS in 5K SDR mode for 2K scans.

My Arriscan runs at just about 2FPS in 6K HDR RGB mode, expect to pay more than $2/ft for HDR true RGB 16bit scans and I would expect a Director 13.5K would be even more I am not sure if anyone has one yet but I would ask $3/ft for 6K and $5/ft for 13.5K scans on that machine if I had one.

As for the Archivist I can let you know in about 3 weeks when I get mine, I will sit it next to my absolutely not obsolete Scan Station SSP with 2-flash HDR for 35mm and 16mm. Beyond the perfectly working optical pin registration on the Scan Station as a plus over the HDS+ the Archivist has Mag sound for 8mm and 16mm that works. Add the speed and total reliability plus a million at the same time file output formats to the mix the LG machine is way ahead.

As for Liquid gates I have 8mm 16mm and 35mm full immersion Perc based gates for the Xena scanners (5.4K and 9.4K machines) expect to pay allot of $$ for any machine with real full immersion liquid gates for films which need this for damaged base scratches. Not every damaged film needs a liquid gate but if they do then it is a very consistent way to fix base problems without having the variability of who and how is doing digital repair, the base scratches are gone and more time can be spent on fixing other stuff.

Basic scanning up to 4-5K prices have come way way way down the Spirit 4K I have cost $2.2M in 2009 when it was built, the cost to run it made the cost of scans allot. Also the expectations for fast turnaround are higher than ever so scanning to DPX and rendering even with scan and renders going simultaneously becomes very slow for 4K and higher res DPX scans.

New LaserGrpahics Xena Kinetta HDS etc. color sensor scanners cost pennies in comparison and scans up to 5K are kind of commodity and the scans are really good. Businesses have to make money to keep the doors open the payroll taxes paid and electricity on, so $0.15-$0.25 more per foot for 4k/5K over 2K is just a really small amount to pay for more pixels in the overall scheme of things.

YMMV

-

14 minutes ago, Phil Rhodes said:

If we're talking about CRI, we're talking about principally white light. Are they using white-emitting, phosphor-converted LEDs for these scanners, then filtering it green for the green flash?

No and LED fixtures like the Arri Skypanel or the Aputure LED do not either they use RGB LEDs similar to the scanners.

From Arri:

"

SkyPanel is a compact, ultra-bright and high-quality LED soft light that sets a new standard for the industry. With a design focused on form, color, beam field and output, SkyPanel represents the culmination of more than a decade of research and development of LED technology at ARRI.

Incorporating features of ARRI’s successful L-Series LED Fresnels, SkyPanel is one of the most versatile soft lights on the market, as well as one of the brightest. The SkyPanel ‘C’ (Color) versions are fully tuneable; correlated color temperature is adjustable between 2,800 K and 10,000 K, with excellent color rendition over the entire range. Full plus and minus green correction can be achieved with the simple turn of a knob. In addition to CCT adjustments, other control options are available such as: hue and saturation, gel selection, RGBW, source matching, x,y coordinates, and 16 professional lighting effects programmed into every fixture."

-

12 hours ago, Phil Rhodes said:

One issue which springs to mind here is that this is, we're told, a scanner using RGB illumination and a monochrome sensor. Much as that's great with respect to getting no-compromise cosited RGB information, using LEDs to do this does raise a couple of concerns. There's a decent red emitter available, but most (not all) LED blue is more royal blue than the deep indigo we might prefer. Green-emitting diodes, in particular, are notoriously not a very deep green. I have never looked into this formally, but I would speculate fairly confidently that there are deeper greens in film negative than the green of the sort of LED that is likely to be used in this sort of application.

For what it's worth, the filters on a Bayer or other CFA sensor also tend to be rather feeble and that's one reason Bayer cameras struggled for years to produce workably accurate colour, until people got smart enough to apply a lot of matrixing. This probably wouldn't ywork so well with RGB LED scans because the problem isn't solely that the green is unsaturated - it's pretty saturated - it's just too yellow. There is not much ability to fix this sort of thing in post.

Does any of that make sense to anyone?

1. There are more expensive LEDs which are in the right color spectrum range for film scanning and also for LED high CRI lighting, so it is just a matter of cost and devices for the LED Lamp for any of these scanners.

2. There is allot Alooooottt of color channel cross talk with any Bayer mask sensor, the dyes used are not strong like a dichroic filter. So that is the big disadvantage with a fast CFA scanner, just like with the digital cinema cameras. A matrix or LUT or combo can tune the system back to better especially if the LED lamp if properly balanced for the film and the CFA of the sensor before a matrix transform is applied.

-

4 hours ago, Dan Baxter said:

Robert, interesting though your vid is, it has noting to do with the question. Bayer scanner question not RGB.

Well the conversation strayed allot and I think people might like to see how a machine like this does sequential RGB HDR color Pin Registered scans.

so there is the Arri

-

-

2 hours ago, Tyler Purcell said:

Don't you have to lock-in a frame rate on a Pro Res file creation as the scanner scans, on let's say a scan station?

You can use Digital Rebellion's Quicktime edit to change the metadata on a Quicktime / ProRes file to whatever frame rate you want. This is just a metadata edit that tells whatever plays the Quicktime file what the playabck FPS is and it is an instant change no render. This same 'Clip Conform" setting was in FCP Studio7's Film Tools.

There are probably other Quicktime editors which can edit the metadata, Quicktime edit is just the one I have been using.

-

1

1

-

1

1

-

-

On 10/1/2022 at 11:53 PM, Tyler Purcell said:

I think it's a one man band.

Similar to Jeff Krienes at Kinetta Rennie runs it and has other people build parts do wiring etc.

The Xena is "technical" but not as technical as running or installing an Arriscan or DFT Scannity or Spirit 4K it is fairly easy to use and I have had staff at Cinelab run Xena scans pretty easily. There is allot more under the hood control on the Xena in the GUI than there is on the ScanStation.

-

1

1

-

-

The Arriscan does 2 exposures in HDR mode the exposure time is set by the base calibration and you cannot change the times on that machine. The Xena Monochrome you can set the exposures for both the first and second flash and the LaserGraphics Director (Now a 13.5K machine) can do 3 exposures.

-

19 hours ago, Larry Baum said:

The data has to be stored relative to something though doesn't it? I'm still not understanding how now. Either simply whatever the filters on the scanner's camera are or something else if they decide to remap it. At the end of the day, it's basically just a DSLR inside the scanner in a sense, taking a digital picture of each frame. Any DSLR RAW photo stores it's data relatively to the raw performance of the sensor + color filters. Any program like say ACR in Photoshop that loads it properly goes to a custom table that the software maker creates to look up what they found the proper primary locations to be (would be nice if the camera makers just gave it in the metadata but they seem to wanna be all secretive).

Well actually not really, especially on "real" RGB scanners which shoot each color with a monochrome sensor and RGB+IR LED lamp pulses, these are mapped into a Cineon Log curve to make 10bit RGB DPX frames. So there is no "Raw" file to be demosaiced as each channel is a full scan record. With a 16bit DPX or Tiff the linear data is mapped into the 16 bits from the sensor, the Arriscan for example uses a 14 bit ALEV monochrome sensor and in 2-Flash HDR it is a full 16 bits of data per channel for each RGB color. So it pulses the lamp R+ R- G+ G- B+ B- (and IR if a dirt map is to be made) in 2-flash HDR 16 bit mode, which runs at about 3 FPS scanner speed. The important thing is not to clip the file, i.e. to get all the density range on the film into a digital container without losing any detail in the shadows or hilites.

Scanners with CFA cameras (Scan Station Kinetta etc) basically mimic to the best degree possible the operation of a "true" RGB scanner by setting each RGB LED lamp pulse to just below clipping on the clear part of the film base, then they do either a Matrix or 3D LUT in the scanner to fix the color channel cross-talk from the sensor's CFA dyes and that is generally then mapped into a RGB file like DPX or ProRes4444.

I can ask some high end colorists who work on Marvel films etc. but in general there is no setting color space from a film scan the color space is set really by the display device and space you are grading in, not by the scanner.

-

1

1

-

-

On 9/27/2022 at 7:55 AM, Simon Wyss said:

Do not expose more than 4,000 frames on a nominal 100-ft. roll. Lab workers need the freedom to shorten the developed length back. Else a portion will get longer and longer by the overlength you claim and the leader added by the lab, if necessary for printing. Of course they will respect the netto length how ever it lies within the brutto, say, 109 feet.

We only really cut a few inches off either end of the roll to build a processing flat (usually up to 2000 feet of film) so I would recommend just shooting the whole roll and be aware that the beginning (usually exposed from loading) and the end will have a bit taken off for processing.

-

1

1

-

-

So try and find out, load a 100ft roll in open light and load a roll in darkness, this is a medium experiment for yourself.

If you load your Bolex in bright sunlight you will most likely get allot of flares on the edges of your film stock. If you load your Bolex under a blanket you will get not much or no edge flares on your daylight roll.

Hold your daylight roll up to Sol and get super mad flares on the roll.

-

1

1

-

-

Or honestly go waive $60k in LaserGraphics direction and get a Archivist, LG had worked out scanning for the non technically minded.

The machines just work and you don’t need to know CERN scientific Linux (Arriscan) or what the encoder count to perf ratio of your gate (Xena) or Suse Linux Cinfigs (DFT Spirit/Scannity)

or go ask Jeff about the baby Kinetta if you don’t have or cannot get $60k he told me that machine is $35k with a 5K camera.

-

If you need a small machine for 8/16 you should look at the “baby” Kinetta from Jeff Kreines its in the $35k range.

sorry to be sharp toned but even LaserGraphics is a fairly small company and other smaller scanner builders are even smaller. They don’t have staff like Mercedes so more concise communication is necessary.

-

1

1

-

-

Companies that make specialized machines like LaserGraphics, Phase One DCS Arri etc. are pretty good at being able to tell real customers from people who will never buy anything.

They call me back, because I have spent hundreds of thousands of dollars on equipment.

If you don't have a phone how are you going to run a business or buy a machine?

-

2

2

-

4

4

-

-

3 hours ago, Dan Baxter said:

Lasergraphics finally let you have HDR on the SS Personal?

They can have bugs, however even with bugs they are dead-reliable. You rarely need to put film through them more than once, and that would be important to many customers that don't want their film "over handled". They'll cope with warped film that other scanners won't do as well.

Well they did not "let" me have HDR for the SSP I paid allot for it, but it fixes my primary issue with the machine which is the FPN on the 5K Cmosis camera and that makes it a more useful machine for 35mm and 16mm scanning.

The Scan Station has some sharp turns so it is not perfect for the most warped film but it works mostly, I have put film through the Xena that just would not go through the Scan Station.

-

1

1

-

-

I would just run it as normal E6 as 9 years is not too long really and it is a slow speed stock.

-

1 hour ago, Daniel D. Teoli Jr. said:

That's an impressive machine. They offer training videos and they give you all the prices upfront!

Does it come with a dedicated computer like the Lasergraphics or do you supply your own?

How is the image qualty for 16mm compared to the Lasergraphics? You mention 8mm. Is that your main use for it?

How is it with warped film? Maybe they will make a tabletop archivist model.

I Have two Xena running a Spirit 2K a Spirit 4K an Arriscan and a Scan Station SSP with HDR now.

I am likely winding down the use of the Spirit(s) as they are great but complex and power hungry.

The Xena system is sort of what you build it to be, or what you have them build for you. I am re-arraigning one Xena shortly adding a 9.4K x 7K sensor that will scan 8mm 16mm 35mm and 65mm/70mm. The current Xena 6.5K config has been used to scan work for NFL Films Nike Studio TV and major Music Video work in 16mm and 35mm. It makes DPX frames and is not slow but not fast either. Xena has features like GPU Perf stabilization. I have a second Xena with a 4K Sony pregius (4112x3008) sensor that I run all of my 8mm on at Cinelab, I can scan 16mm and 35mm on that machine I just run 8mm on it though mostly.

Scan Station is unparalleled in it's dead reliability near bug free and fast operation, the scanner just works and runs like a top. Argue the fine points but everyone has a Scan Station and they work.

Xena is fussier and you can get access to all the "under the hood" stuff you can build you own transport configs quickly so if you have 7 perf 35mm scientific film from a camera built by a maniac by hand you can just config the transport and GPU perf stabilization to run it.

You can DIY a IMAX gate and transport setup and config a Xena to work. You can select the camera you want and integrate it. So build a Xena with a 6.5K Sony and a top quality lens and you can get results on par with Scan Station or Kinetta it will not be as fast nor as dead reliable as a LaserGraphics scanner but it works and works well.

Totally different approaches to building a scanner.

-

What manufacturer is the processor? Allen?

B&W Negative is pretty easy to setup and maintain honestly it is the simplest chemistry basically wash developer wash fix wash final drybox.

B&W Reversal is allot more complex and the chemistry exhausts allot faster than negative.

The machine itself is fairly easy to setup and get running as long as things like the tires and spring bearings etc. are good and or available. Most of the rest of the machine is drive components like motors and chains and sprockets or tanks and pumps which are all off the shelf kind of parts.

DM me for more advice..

-

1

1

-

1

1

-

-

18 hours ago, Larry Baum said:

But whatever loads them needs to know what the R, G, B values stand for. Where on the CIE plot is the red primary that the data is in reference to, to make it easy assume an 8bit per channel (and yes I know it's more), so what would 255,0,0 represent?

I think this assumption is incorrect the color space for a film deliverable grade is chosen and the film scan is a RGB value (linear or log) with 0-1024 values for each color in 10bit. As long as the scan is not clipped either in the shadows or the hilites the color balance can be set to the desired look of the colorist. Same with Arriraw or other formats they are color space agnostic.

-

2

2

-

-

On 9/17/2022 at 3:36 AM, Larry Baum said:

Another problem is if say the files really did have wide gamut primary referened data in them, then if the DPX16 files has zero metadata about the color gamut at all then how in the world would any program know what to do with it?

I question your workflow from this.

Motion Picture scans generally do not have any color gamut assigned, you take a DPX or TIFF scan and put it into Resolve or Baselight etc. and then work in the color space you want to work in, the scanner does not assign a color space. So you can take the 16bit TIFF sequence and run in ACES or BT2020 etc. and off to the races you go....

DNG is not really a format that any motion picture post uses to work in, so I have a few questions.

1. Are the cDNG files directly from the Scan Station?

2. Are the cDNG files from a Negative scan or Print positive?

As far as I understand the Scan Station can make cDNG files but they are just the unprocessed data from the Sony Pregius IMX342 sensor so a negative scan will not be encoded into LOG nor will the cDNG file appear loaded into a piece of software as a positive so you will have to do that transform.

The LED Lamphouse is set to the just below clipping balance of the film stock per color channel which is your primary light source for scanning.

The Sony Pregius IMX342 sensor has a CFA (Color Filter Array) built by Sony and the color dyes are not something a scanner manufacturer can choose, these are off the shelf machine vision cameras used by LaserGraphics / Xena / Kinetta / VarioScan etc. So the scanner manufacturer has to do some math in the Debayer and encoding and if you scan from a color sensor system to cDNG you are likely missing any color science the scanner manufacturer does to write to DPX or TIFF or ProRes and also the cDNG precludes using a 2-Flash HDR process etc.

So if I were trying to figure this out I would drop all the still processing apps and work in Resolve or some other system for motion picture work and go from DPX or some other motion picture file format.

-

1

1

-

-

If you want to DIY I would strongly encourage a look at the DCS Xena system.

You can buy a full running pinless GPU registered scanner or a full running Oxberry pin reg scanner but you can also buy modular parts from them to build your own machine. The software is extremely sophisticated and has all the features like GPU perf stabilization and proper sound reading. There are basic modules and when is supplied is the software, a motion control and LED lamp control module and a LED lr LED+ IR lamp.

I put more than 200,000 rolls of 8mm through our 4K Xena in the last four or five years with excellent results for example and scans from the 5K and 6.5K Xena machines have run for NFL Films Nike Major music videos and features etc.

http://digitalcinemasystems.net/?page_id=17

-

1

1

-

-

1 hour ago, Tyler Purcell said:

That's what I'm also very confused.

I guess his idea is that because digital cinema imagers can deliver a wider gamut, why can't film scanners.

Yeah i am a bit confused too.

As far as I understand it film scanners generally do deliver wide gamut and I don''t see how in the imager/lamp or lin-log or demosaic math the gamut would be intentionally limited.

This is particularly true with a "True RGB" scanner that uses a monochrome sensor and multi flash R,G,B IR or a 3-line array.

I know the LEDs used in the lamp on all of the newer scanners have specific qualities and center point wavelengh for each color which are then modulated for intensity for each R,G,B channel. The basic idea is to set each channel's intensity to just below clipping on a clear part of the base as that gets the basic color balance and most DR set to the particular film stock.

Both cmos and ccd sensors are linear devices which usually have 12-bit A to D (some are 14bit or even 16bit) so when scanning negative the linear response of the sensor has to be encoded into Log as part of the process, positive films are scanned linear. Multi flash gets you 2-bits more precision and can help overcome the noise floor a sensor might have.

It would seem to me that any gamut limitation would be in the area of the spectral response of the LEDs used in the lamp and the color dyes used in the CFA Bayer mask on the sensor. I doubt any scanner manufacturer is choosing LEDs with limited spectral response. The color cross-talk between channels on a Bayer sensor can be considerable and a matrix or profiled 3D Lut is probably in the pipeline to deal with the characteristics of the color sensor used and there may be some limitations there in comparison to a True RGB scanner.

-

1

1

-

Is it possible to get wide gamut color out of Scanstation scans (color primaries wider than sRGB/REC709 locations)??

in Post Production

Posted

The Spirit (all versions) uses a Xenon lamp (700w on the newer 2K/4K) and it has a filter wheel and a few other filters auto drop in which alter the light before it hits the quartz rod to illuminate the line slit on the gate. These filters do not do RGB balance but are for different stocks like positive or negative etc. The color separation is done with dichroic filters on the CCD line arrays.

There was a telecine made by Sony called the Vialta that initially had a Xenon lamp and a dichroic box like the B&H printer and a F950 3xCCD camera image head. I know they eventually went to RGB LEDs for the lamp house in a version upgrade. As far as I know that early Vialta was the only Xenon RGB balance-able lamp house scanner made. Everything else has been a hot lamp Xenon or Metal Halide (Northlight) etc or eventually individual RGB+IR LEDs

The Arriscan has always been RGB+IR LEDs in a (beautifully made) integration sphere. The Northlight 1 and 2 eventually saw FilmLight make a RGB+IR LED replacement lamp.

I think with the right high end RGB LEDs (maybe a mix of 2 colors of R and G ?) that LEDs work as all the scanners running these days (except the Spirit 2K 4K) are running some form of LED lamps. I am not exactly an engineer but nobody is complaining about Arriscan or Scannity scans color fidelity as far as I know.

I was thinking that a newer daylight balanced Xenon equivalent LED film lamp might be a possible replacement for the Xenon lamp in the Spirit 2K/4K series scanners to keep these true RGB scanners relevant.