-

Posts

3,324 -

Joined

-

Last visited

Everything posted by Aapo Lettinen

-

yes like others said, find some great local stories and make local micro documentaries and short films based on real life around you. The locals will appreciate it greatly when you want to tell about their life and history and will surely support you in some way. Don't make generic stuff like everyone else in the World does (copying Hollywood scenes and such), tell stuff about the real world you know best and those would actually be much more interesting to outsiders too so it would be easier to post them to festivals and such if you like or gain internet views as they stand out from the basic indie "shoot shoot bang bang" or "boy meets girl beautiful city lights" stuff 🙂 at some point in the future you may have to move to bigger town but at the moment you have to gain experience and have a safe learning environment so definitely stay local for some time first and see what kind of "film industry" you can build there!

-

I will start working on the rods base design later in October. price is 350usd + shipping . It will have additional features I will talk about later when having the basics designed first. It will be really really cool system but will reveal the rest when having the basic body finished first 🙂

-

Eclair Flea Market

Aapo Lettinen replied to Gregg MacPherson's topic in Marketplace Listings Under $200 / €200

can you post photos of the motor which runs slightly too fast? it is worth repairing by my opinion, just wanting to look if it happens to be something I have idea how to open for repairs -

First finished 10-speed motor. Will post better pics later on, will now concentrate on getting the rest of them finished. I still have parts for one or two of these and can assemble them in late October if needed. price 1200usd + shipping. those are the last motors available for the ACL after which one would need to wait to December2025 if wanting any ACL motors and the ACL2025 version is much more expensive than this one 🙂

-

Inside a 24fps Crystal Controller (Photos)

Aapo Lettinen replied to Kamran Pakseresht's topic in Bolex

I have used mcu dividers for many years and almost all the finished stuff uses them, I'm just not using the 328 as have found more practical mcu's for my projects. Even my first Konvas 15epss motor partially used software dividers, it was just a hybrid system which generated some frequencies with "old-school" binary dividers too because it was fun to design and made the dual rotary switch selector system a bit more effiently working. -

Eclair Flea Market

Aapo Lettinen replied to Gregg MacPherson's topic in Marketplace Listings Under $200 / €200

the same technology than the NPR motor uses will be used on the 2025 version of my ACL motor. I also have some Arri designs, eyemo stuff, cinema products, etc but they are a bit different. Designing these systems is case by case and I partially combine projects when possible but most of the time that is not possible. Combining projects saves resources but it does not make it easier to develop them, often it takes more time actually and only done to save money -

Inside a 24fps Crystal Controller (Photos)

Aapo Lettinen replied to Kamran Pakseresht's topic in Bolex

ever wondered why watch/clock crystals are always 32.768kHz? That is because that frequency can be divided with one binary counter IC to exactly 1Hz frequency when the 32768 is divided half 15 times in a row. that 1Hz signal the advances the clock once each second. same logic applies to other crystal oscillators using simple dividers. you know what end frequency you want and what dividing tools you have, then calculate what the needed crystal frequency is and check if that exact frequency is available from the suppliers -

Inside a 24fps Crystal Controller (Photos)

Aapo Lettinen replied to Kamran Pakseresht's topic in Bolex

btw still have tons of my old test boards which use simple counters to make reference frequencies. making new ones too but the old ones are possible to get cheaply and quickly so can be very useful if you for example need 240Hz crystal frequency for something or if that Bolex motor controller is actually 240Hz / 10slot system , in that case I have like 5 or more board options as I used to make lots of stuff for 10slot encoders so you could cheaply add more crystal speeds to that bolex controller by feeding the extra speeds from my board. I used to do old school dividers before getting lazy and starting to do everything with software 😄 the old school stuff is not compact but they are easy to understand and have advantages if wanting to use simple rotary switches for speed selection. and are cooler looking too 😄 -

Inside a 24fps Crystal Controller (Photos)

Aapo Lettinen replied to Kamran Pakseresht's topic in Bolex

for example if you have 24kHz crystal you could use for example 74hc390 dual decade counter to divide the crystal frequency with 5, then divide with two, then divide with 5, then divide with 2 to get a total division of 100 and end result of 240Hz square wave with 50% duty cycle. It is entirely possible they made it this way, you can look what the ic:s on the boards are and how they are connected. It would be very easy to divide the 240Hz with a single counter IC so there is pretty good chance there is 390 ic on board as it would be the easiest and most compact way to get the reference for 24fps if the encoder was 10slot -

Inside a 24fps Crystal Controller (Photos)

Aapo Lettinen replied to Kamran Pakseresht's topic in Bolex

normally older crystal sync devices use binary and decade counters to divide the crystal frequency to a frequency which is the same than the amount of pulses per second coming from the motor's encoder. So if for example encoder generates 10 pulses per one frame of film shot, one would use dividers to divide the crystal frequency to 240Hz square wave for 24fps (24 * 10) and then make circuits which match the motor speed to that 240Hz signal. using binary and decade counter dividers necessitates that the needed end frequency is directly dividable using this simple counter technology. so only certain encoder slot counts and certain crystal frequencies could be used to get the needed end result. For example if using 10slot encoder (10 pulses per frame) it is possible to divide the needed 250Hz for 25fps from 2.048MHz crystal and 240Hz for 24fps from 2.4576MHz crystal. But both 250 and 240Hz cannot be divided from the same crystal frequency. So if you want to have multiple speeds which cannot be divided from the same crystal by simple old technology you would need to make two separate crystal oscillators with separate dividers (for example one generating 12.5fps, 25fps, 50fps, etc. and another generating 12fps, 24fps, 48fps, etc.) . with microcontrollers one can do the division with software which opens tons of better possibilities including creating both 24fps and 25fps references from same crystal etc. you can see the old technology limiting factors when looking the crystal frequencies the old crystal motors can run at. if starting to calculate the frequency dependencies you will notice that they are all divided from the same source and that is why there is some oddball frequencies too which may not be used for anything useful, they were mainly added just to get more presets because more is better 🙂 on newer systems where programmable dividers or microcontrollers used the selector may have every preset carefully though through and selected rather than taken what you got. big difference when you can actually decide what fps each preset is rather than selecting a set of random framerates easiest to divide from single source just because there is one fps you want and the rest "come with it free of charge) -

Eclair Flea Market

Aapo Lettinen replied to Gregg MacPherson's topic in Marketplace Listings Under $200 / €200

for example if checking that original crystal on the old camera motor you would need a frequency counter which is orders of magnitude more accurate than the crystal. 10 times or more should be enough but it warrants a frequency counter which uses tcxo or ocxo as a reference -

Eclair Flea Market

Aapo Lettinen replied to Gregg MacPherson's topic in Marketplace Listings Under $200 / €200

the crystal generates a multi-megaHertz signal which is divided down to suitable level to be used as a reference for motor timing. most older motors work so that the crystal frequency is divided enough to create low frequency signal (like 600Hz) which is same frequency than the signal expected to come from the motor's speed encoder if the motor is running at the desired speed (for example 24fps). the electronics compare the motor signal and the crystal signal which are supposed to be similar: if they are not, the electronics adjust the motor power up or down until the signals match close enough. so if the crystal frequency is shifted from the original it causes the whole motor to run slightly faster or slower than it was originally intended to be. it has no way to know that there is something wrong because the crystal is its only timing reference so it has to trust the crystal is always right 🙂 getting "exactly correct timing" is a huge issue in electronics in general. All clocks and oscillators have drift and inaccuracy and you need much much better clock to be able to compare if some other clock is "correct" or not. None of them is really really correct in any case but some of them are "closer to what they should be" than others. for example on the NPR motors I use temperature compensated oscillators which are more precise than 2.5ppm (parts per million) over the operating temperature range. normal crystals used on crystal sync motors, old or new, have accuracy and stability between about 20ppm and 100ppm when the crystal is new, but it can be pretty poor accuracy after five decades of use even if the stability is still fine. For calibrating the 2.5ppm oscillators I need a frequency counter which has 0.1ppm accuracy in its timing reference and I need a much more accurate gpsdo to test the counter before use and to lock it to if needed, the gpsdo typically has the accuracy around 0.5ppb to 1.5ppb (part per billion). With this setup I can tune the NPR crystal oscillator to be about 0.2ppm accurate in room temperature when it is shipped. Keep in mind that the 2.5ppm is over the full operating temperature range from freezing to over 80°C and if using the camera in room temperature the accuracy is much better. Every clock is always wrong, it is just the matter of making the error acceptable enough in the specific use you need it for. Mechanical watch for example has poor accuracy but they are perfectly fine for most uses they are intended for if you check and correct them daily. But like mentioned if you want to calibrate a clock you need much better clock and calibrating and testing that again needs much better clock. At some point you need to spend hundres of k's to a rubidium atomic clock and even then it still is not dead on accurate and you need something better to check if it is entirely correctly running or not 🙂 -

Eclair Flea Market

Aapo Lettinen replied to Gregg MacPherson's topic in Marketplace Listings Under $200 / €200

or could be aged caps on the crystal which don't have the right capacitance anymore. Or could be both. In any case I think it is the timing reference being off and nothing else wrong with the motor. It is normal for crystal to age and drift and need changing after some decades and the caps will age too even if ceramic which are pretty long lasting. the crystals have estimated aging and drifting values on the datasheets, they all do age and drift more or less. the crystal itself on the crystal sync motor is easy to find and usually possible to change by a person not specialised in crystal sync electronics. the crystal sync devices themselves are often very complex and difficult to tune and repair but if only checking the crystal and its capacitors it could be easy enough for some "normal" electronics repair person to do. If the motor is easy enough to open enough to get to the crystal, it depends on the exact motor model how easy or difficult it is. some motors need almos complete disassembly and some are pretty easy. -

Eclair Flea Market

Aapo Lettinen replied to Gregg MacPherson's topic in Marketplace Listings Under $200 / €200

did not watch the video but that small of a difference might be caused by the crystal aging too much. If it really keeps sync but just runs a little too slow / too fast and the amount is the same all the time. Crystals can often be changed, might be more or less work depending on the construction of the motor (how much it needs to be disassembled to get to the crystal itself) . Some circuits may have calibration trimmer for frequency adjustment which could be off but I have very rarely seen that on crystal motors so probably it is just old crystal being a little too old -

new ALCS compact crystal motor for Eclair NPR

Aapo Lettinen replied to Aapo Lettinen's topic in Eclair

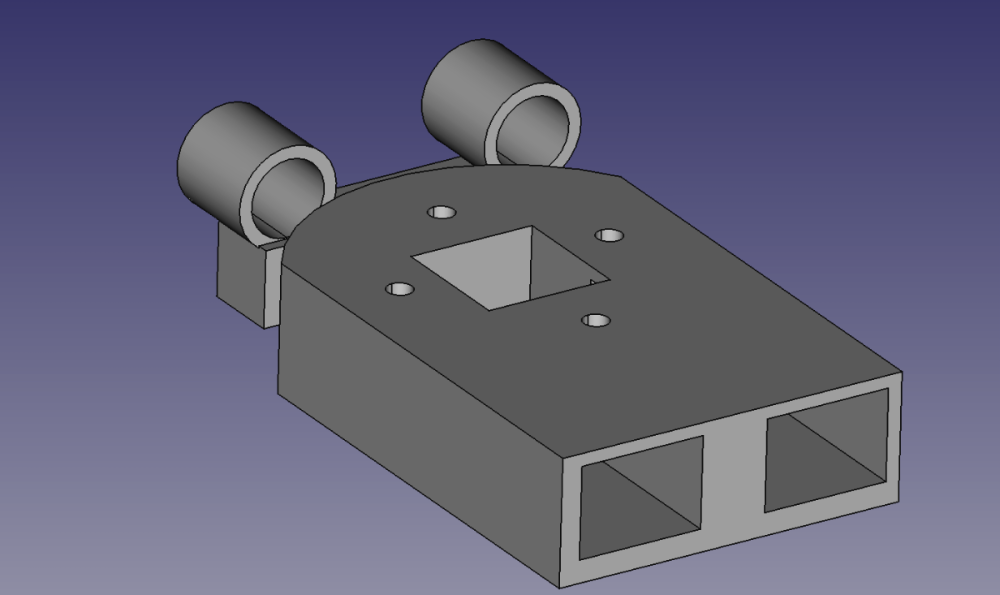

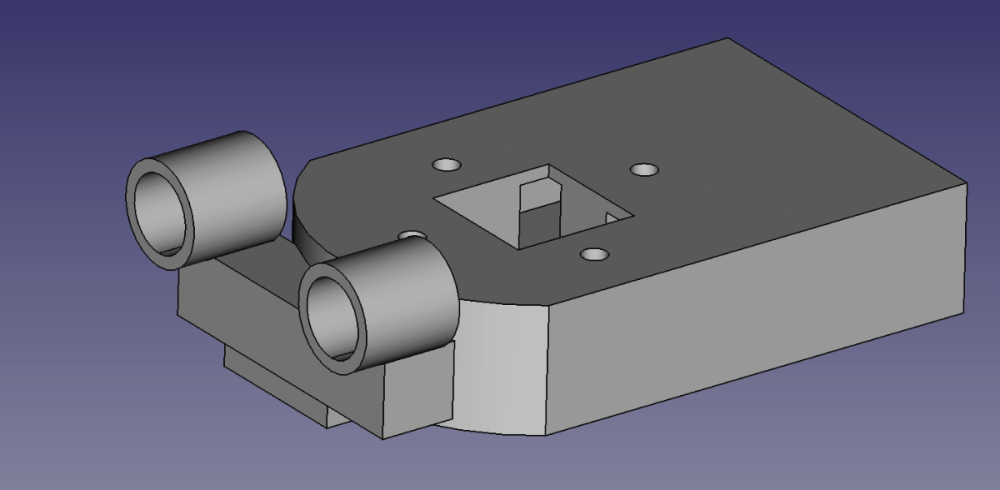

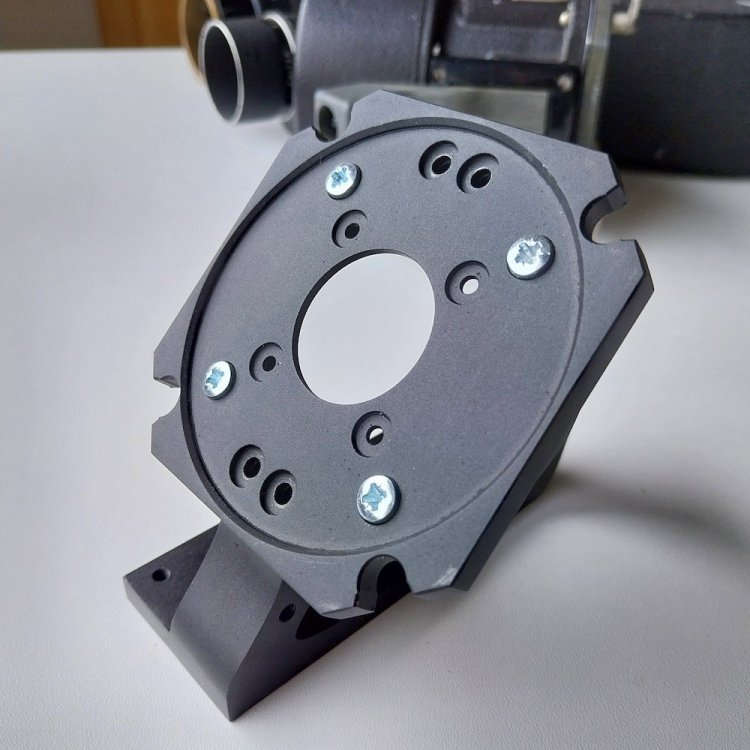

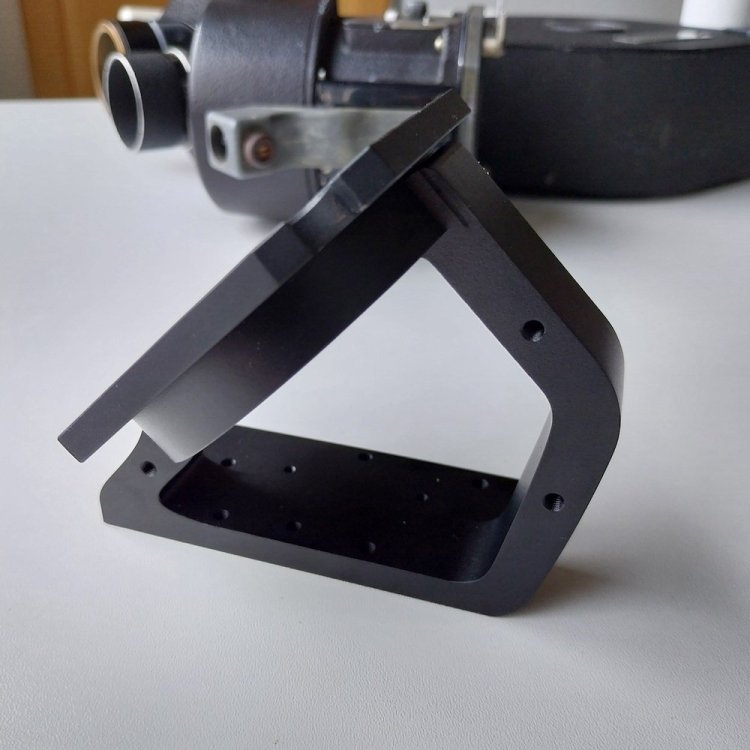

The final CNC machined support bodies of the NPR motor. Very very sturdy, I could stand on it no problem. This is the part holding the weight of the camera and the "skeleton" is machined out of single piece of aluminium which makes it very strong. the camera side mounting plates were sent to final machining now. I will next order at least half of the needed support bodies. -

Some people have asked me about making new electronics for the GSMO camera. Is there anyone here with a gsmo which has non-working electronics and need to restore it in working condition? price range would be something between 1100 and 1500usd for the update and about half a year or so to develop it but would know better if there is orders for this kind of system 🙂

- 1 reply

-

- 1

-

-

mattebox hard mattes to mask out any out-of-frame stray light possible. might help a little

-

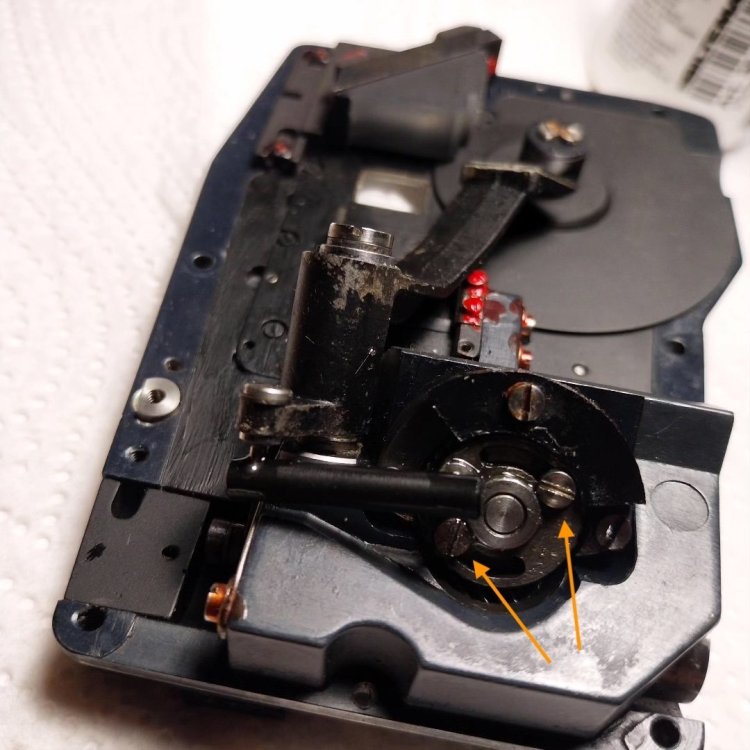

the mirror timing is kind of a matter of taste, has pros and cons how it is exactly adjusted and possibly modified when modifying the gate. I think the most common issue with lenses is that the back element is relatively large and far away from the gate so that the mirror can mask the stray light inside the cavity more easily. so the asymmetrical mirror causes a "shadow" of the stray light which is slightly darker on every other frame when the mirror is on the camera right side, slightly closer to the gate and lightpath when the shutter is open. It is pretty much a matter of tons of testing and when finding a more problematic lens then deciding if wanting to use it anymore. but first maybe checking that the mirror is not badly out of sync, a technician can look your camera to see if it can be better than it is now. Hard mattes should help a little with the flicker issue I think but would not eliminate it, maybe just saving a shot or two every now and then. if being brave enough it is possible to diy adjust the mirror timing if wanting to just try different settings and fine tunings. A camera tech can do it better but it being like me who can't wait for cameras being shipped back and forth then it is interesting to try diy repairs 😄 these screws hold the mirror timing locked and one can fine tune it if loosening them carefully and altering the timing a little. Not recommended to remove any gears for larger adjustments because that will likely cause more harm than good and they are very time consuming to get back to correct alignment, the spacing and everything. So flicker fine tuning possible by those two screws, other stuff dont touch 😄

-

There is very simple way to determine if the cause is the mirror. The mirror swings to left for one frame and to right the next frame. So mirror flicker is every other frame slightly underexposed/slightly overexposed. If your scanned film shows this alternating higher-lower exposure on adjacent frames then it is the mirror. Open the scanned clip in resolve, slowly move forward frame by frame and look on the waveform scope if the waveform slightly jumps up or down the same amount every time you advance a frame forward

-

The acl has asymmetrical mirror swing and certain lighting conditions + lens + settings combinations may suddenly cause visible flicker, or not. Should not happen often/all the time though. If your camera visibly flickers all the time get the mirror timing checked. The acl is built that way to make it smaller. People are fine with it most of the time. But if it starts to give you trouble then get it checked and retimed or modified further to reduce the issue to acceptable level. If it is just one lens giving trouble then trade it to some other lens. If most lenses do that then it is the camera body itself

-

new ALCS compact crystal motor for Eclair NPR

Aapo Lettinen replied to Aapo Lettinen's topic in Eclair

Two days left to order at the normal price 😮 -

yes Panasonics have very different look. they are great for documentary and mixed format stuff but the codecs etc are not super handy for narrative production and still camera body is not optimal for that kind of stuff either. When they at some point get cfexpress and internal raw codec to their full frame cameras it will be better codec-wise but proresraw is still not very optimal for fast-moving productions because it does not work with resolve and no one wants to edit anything serious with premiere and fcpx lacks the good enough grading features so it needs to be transcoded to really work efficiently with it. so on most stuff one either shoots normal prores or similar easy-to-manage codec, or if exclusively using resolve for anything then can user blackmagic raw. the Pyxis might be much better deal if they get the imager updated and some framerate stuff more attractive. There is still the issue of Blackmagic generally making unreliable products but I hope they will improve eventually so that the end user does not need to do the quality control which really should be done in the factory instead of shipping non-checked cameras which might or might not work

-

ALCS Single-Speed Crystal Controller for CP16R

Aapo Lettinen replied to Aapo Lettinen's topic in Cinema Products

It looks like it is good time to wrap the 1-speed CP16R project for good. There was very little demand for it after all ( I sold two kits and installed one to my own camera). And frankly speaking I want to get rid of the bits and pieces I have saved for this project and only save the essential stuff needed for possible repairs of the existing systems. I am concentrating on Eclair and Arri motor projects for now as there is more demand for them and I am able to finance the projects better than these Cinema Products systems which seem to create lots of losses and there is fewer active users. It is still possible to order custom made crystal update kits for the CP16R of course, for example multi-speed ones with basic display and shutter parking etc, but there is minimum order amounts for custom work (typically from 2500 to 3000 usd minimum order paid upfront and one would get maybe 2 or 3 kits with that price depending on features). Custom work has the advantage of being able to affect the features and user interface if you have special features in mind. The disadvantage of custom stuff is that it is not possible to order single ones (well it is but it would still cost the minimum of 2500 or 3000usd so as well you could get two or three and sell the rest to others). -

yes looks like a lost loop or more generic pressure plate issue

-

new ALCS compact crystal motor for Eclair NPR

Aapo Lettinen replied to Aapo Lettinen's topic in Eclair

One week left to order at the normal price. I will need to send the first final mechanical parts to cnc machining next week which is why the prices will go up 2nd October as it will cause me extra costs if needing to order multiple batches of parts. So like mentioned before, I really need to know the exact amount of motor orders soon! if being late then the higher price needs to be paid so that I can cover my extra costs. Payment schedules can be negotiated and it is possible to pay these in 3 parts if needed. It is just that I need to get all the custom mechanical parts made in batches of 5 or more to get good price on them and I am only ordering the exact amount needed to save resources on other parts of the project (the mechanical parts are expensive enough that I can't stock extra ones, could lose thousands of dollars if doing so)