-

Posts

967 -

Joined

-

Last visited

Everything posted by Perry Paolantonio

-

I just need to address this specifically because it's been bothering me all weekend. Let's break down Lasergraphics' text, shall we? "Built in color grading tools for easy dye fade correction": This exists, and works to the extent that many people require. "applied during scan, eliminates secondary post processing step": This is also true. If your goal is to make an access copy of a print that has corrected for dye fade, you can do that and it saves a step. If, however, your goal is to make an archival scan of the film, then this is the wrong approach. But this gets back to something we've discussed before: The person operating the machine has to know what they're doing and if you're using the scanner to make archival scans with grading done in the scanner, I would submit that you don't know what you're doing and should do a little bit of reading about how this is all done first before proceeding. The dye fade correction tools are there primarily as a convenience and anyone who is spending $50,000 - $200,000 on a film scanner ought to know that. Even Lasergraphics will tell you this and they will tell you that you shouldn't be relying on their grading tools for mastering work. They are rudimentary controls and there's no way to properly monitor the image because it's all being displayed on a computer screen that is subject to Windows' color management. Basically, don't do that. If you know how to grade footage, you know this is not how it's done. This feature is there for people who want to make a quick access copy. We don't use it, but could, and it works fairly well if the film is consistent (such as a print made from one element with uniform fading). It does not work well if the film is spliced together from multiple sources. We often make a secondary MP4 file alongside a master flat scan, with a one-light grade done in the scanner for the access copy, though we do that one-light manually, arriving at an average grade that doesn't clip or crush anything, even if there are multiple sources. That wouldn't work with this tool, but one should know that before using it. This morning we captured 30 seconds from a short dye-faded 16mm print and I just slapped this video together. The HD version should be done processing soon, but you get the idea even if you're limited to SD playback from YouTube. I am no longer waiting. BMD confirmed on their forum that the soundtrack reader in the cintel is essentially what you get in a projector: a red light source with a photocell. There is no camera there. They are compensating for wow and flutter by monitoring the capstan with an encoder.

-

Daniel, we last scanned film for you 4 years ago and haven't spoken other than via these forums, since. So I don't recall what you're referring to. That being said, we don't put up example scans for the following reasons: To do it properly you need to post, at minimum, ProRes files, or something uncompressed. These need to be viewed on the local machine and *not* streamed. If you put stuff on YouTube or Vimeo, the compression they apply to make it streamable is out of your hands and there's no guarantee it looks correct. Also, the compression applied will in many cases destroy the film grain, so it's not an accurate representation. Every reel of film is different. Posting a test scan from one reel is not representative of how another will look, because there are too many factors involved (type of film, number of generations from the original, damage to the film, fading, quality of the print or intermediate, sharpness of the original footage, etc). Back in the day, when I worked for a company that made one of the early computer-based nonlinear edit systems, we participated in several "shootouts" of these systems. Ours against all the others, using the same footage. Mostly it was about the quality of the picture, which was often coming from an analog tape source like BetacamSP. So you could objectively test, because you were looking for things like the level of compression for the same size image, etc. The people doing the tests were objective third parties. I would be happy to have someone who knows what they're talking about (not Dan Baxter) send us a reel to scan, with specific parameters, if it's going to be compared with other scanners and presented objectively. This means each scan should have the same cropping, should be scanned to the same format, and should be scanned in similar ways (eg: all flat scans). Then someone who knows what they're doing should take those files into a color grading system to look at them a bit deeper and see what they have to work with: push the grade as hard as you can to see where the image falls apart, stuff like that. I'm only willing to do this if it's someone credible doing the work though, because it's too easy (as you can see from the Fleugicker paper you posted in another thread) for someone's assumptions about what's happening to color their conclusions. That being said, I think you'll find that it's impossible to truly, objectively compare these scanners. They all have their strengths and weaknesses. Some are optimized for negative, some for print. They're all going to have different features, so you may not be able to do some tests on certain machines that you can on another, and so on.

-

I have two working eyes and a brain. And I also have email and text message confirmation from Stefan, the CEO of Lasergraphics and Steve, the owner of Galileo Digital, the reseller that it is either/or. You cannot have both, it is one or the other. Ok, whatever you say. The record on this is pretty clear to anyone who wants to search this forum that this isn't true. I don't have time to dig up every claim but you have in fact said that the Archivist has a hardware optical reader, more than once. No, your guessing wrong. We don't have it because we have the hardware reader. The software reader is software. It's part of the application and does not require a license, as it's part of the base module application. If you have a hardware reader, the software reader is disabled You get one or the other. Again, confirmed with Stefan and Steve separately. Why is this so hard to understand? It has nothing to do with model year of the scanner as it's purely a software option, and it is Lasergraphics' decision to give you one or the other. No, this is not how Lasergraphics does it's software updates. If it was there but not licensed, it would say as much in the license window where that stuff is listed. It does not. If you pay for a support contract you get the same software that runs on machines shipping from the factory today. The only features that are not necessarily enabled, are hardware based. For example, the original machines didn't have variable tension adjustment for the dancer arms. Without a hardware update to add that feature, you cannot use those settings in the software. But they're there. You are the one making unsubstantiated claims in a public forum. I'm not going to message you privately about this. You are spreading misinformation about something you do not have direct experience with, and in many cases you're making assumptions based on incorrect guesses as to how things work. Your claims are not credible, IMO, and I wish you would simply stop talking about things you don't know about.

-

Ok, whatever you say boss. Just for the record, every single product catalog photo you've ever looked at for anything (shoes, clothes, film scanners, food), has been photoshopped too. You have said or implied many times in this thread and others that you can get an optical track reader for this machine. Two examples: I am pointing out that the image of the machine that is on their web site, WHICH IS THE MACHINE THEY SELL, is incapable of mounting the optical reader without major modifications that cannot be easily done. The image you are pointing to is clearly an early model built on a Scanstation deck plate. That's why they covered the hole you see. And for the record, no, it's not available as an extra for the Archivist. you're quoting an early price sheet you got from an Australian reseller. Contact Lasergraphics, ask them if you can get this, tell us what they say. They're the final authority, not your reseller. Well, there's the difference. You've got opinions, I've got facts. Show me an example of something that's false or misleading. Don't keep bringing up the Dye Fade Correction, because that, in fact, is a feature that exists on the scanner. It's called "Auto Color" and it's basically the same as auto color in DaVinici Resolve. We don't use it because it typically only works for a single shot and is a bit heavy handed, and it defeats the purpose of doing a flat scan. But I know several home movie transfer services do use it. it works by using the built-in scene detection in the scanner and when the scene changes it apples a new auto color correction for that shot. As you might imagine, this doesn't work perfectly. When I'm in the office I can post an example from a dye faded print with this on and off. It's a real thing that has existed on Lasergraphics scanners for as long as I can remember. I think this is the crux of the problem. You have "beliefs" about facts that are easily provable. I mean seriously? We have a ScanStation and you're telling me things are different than what I see in front of my own eyes *AND* have confirmed with Lasergraphics? We have the latest software. The software soundtrack reader is not there. Does not exist. No software reader. None. not there. No options in the software for software reading. Lasergraphics tells me that if you have the optical reader, you do not have the software reader. But hey, why should anyone believe them? they only made the machine.

-

BTW, I'm happy to test the same track on a Cintel. The person I talked to sold his or he'd have done it. His assessment was that their ScanStation's audio was miles ahead of the cintel, and that the quality on the Cintel reader is "garbage". Which honestly doesn't surprise me given the manual adjustments (actual knobs) you have to tweak to align the reader and the track. Anything remotely shrunken is going to be a problem in that thing. But I'm game if someone has a sprocketless Cintel they'd like to run that film through. I wouldn't want to put that film through a sprocketed machine due to the level of shrinkage.

-

First off, the image you're showing above is an early model. You've showed pictures of this one before I think. We've discussed this already: The Archivist has an optional MAG reader. There is NO optical track reader available for the archivist, it is software only. What you are showing in the picture above is an archivist that was built on a ScanStation deck plate (possibly due to supply chain issues? They are the same footprint in all other respects). Look at the picture on their web site. There is no square opening above the mag reader. This square opening is where the back of the optical reader enters the inside of the unit. The capped screw holes in the photo above are where the optical head attaches to the deck plate. THE CURRENTLY AVAILABLE ARCHIVIST HAS NO SUCH OPENINGS OR SCREW HOLES: The reader you see there is magnetic. It is not optical. HARDWARE OPTICAL AUDIO READERS ARE NOT AN OPTION ON THIS SCANNER. Direct from Lasergraphics, on January 5, 2022 when you first insisted this is available: "the Archivist does not have a mechanical optical sound reader (it is camera/software-based); it does offer magnetic sound readers" -- Look at it. Where does the optical reader go? It is a three-dimensional object that sits on top of the deck plate and extends into the chassis where the connectors are. There is nowhere to put this. You keep quoting an old price sheet. But man, I hate to break it to you: Now is not two years ago.

-

I am still waiting to hear back from BMD, but have spoken with an owner of one of these who has taken the unit apart. He's also someone who would know the difference between a phototransisitor and a camera. There is NO camera inside for the optical track reader, it works like a projector. Which checks out, as I outlined above, with things like the wow and flutter specs. And they are almost certainly using a hardware low-pass on the audio to cut off everything above 7kHz and 16kHz for 16mm and 35mm respectively.

-

How is that a stretch? it's how sound was read for many decades, including on some late model telecines. Blackmagic bought Cintel for a reason, so it's logical they'd have used some of that tech in their new scanner. As for the timeframe, you clearly have no concept of the work involved in designing a scanner like this. The BMD Cintel is based on late model Cintel scanners, but it's still a different machine. There is no way they could have taken a Cintel sound reader and plunked it onto the new scanner, because it's a completely different machine. A ton of work goes into the design (mechanical and electronic) of these things, even if you're just modifying existing models. If they were behind on something and needed to get the scanner launched for, say NAB, dropping the audio module for a while until it's ready seems like a reasonable decision. Don't forget the cintel design team at BMD is/was tiny. Obviously they planned to include that from the beginning, because the ports were there in the first release I saw at NAB in 2014. In any case we're both guessing so I've asked Blackmagic. We'll see what they have to say. No. you're completely missing my point. I'm not saying they're overcharging. You seem to be implying that because BMD is charging $3500 for their reader, Lasergraphics is overcharging for theirs. This conveniently ignores the fact that the Lasergraphics reader is a totally different design with a totally different way of doing things (I am almost certain) in a totally different class of scanners. As I spelled out above - there are significant differences in how the Lasergraphics reader is working that make it a better design, even if you take the camera vs photocell argument out of the picture. Better design costs more for a reason. I was just turning around your argument to point out that if BMD is not using a camera (as I suspect is the case), the parts involved to reproduce sound are cheap. Of course it costs a bunch of money to design, manufacture and sell these things, and I have no problem with the price they're charging. It's proportional to the cost of the machine. I don't think they're overcharging. In the current lineup, the Archivist is the only way to get the software reader because they don't offer a hardware reader for it. This was confirmed with Lasergraphics last week. The ScanStation comes with the hardware reader. You cannot run both the free software reader and the hardware reader on the same machine. That said, while it's a good value, it is subject to the same issues as AEO-Light is, in that warped film will result in worse sound than the hardware reader. This is in part because the hardware reader is holding the film flatter, but also because it's sampling at a significantly higher rate. What exactly am I "alleging" here? Are you talking about blackmagic? A low pass filter isn't necessarily done in software, though it can be, and in software you can fine tune it to the specific audio you're working with. But if the BMD audio reader works as I expect it does, it's all analog and the filtering is done in hardware: light through the film to a photocell, which converts the light to a voltage. Hardware low pass filters for audio are not especially complex - they can be passive circuits inline with the analog audio signal. Here's a basic explanation of the concept. A low pass filter over 7kHz for 16mm or 15kHz for 35mm (BMD's stated specs for optical audio reading) would eliminate the hiss you hear. Because 16mm sound is mixed to cut off above about 6kHz, and the BMD scanner's frequency response for 16mm caps out at 7kHz, they are likely applying a low pass filter to cut off everything above 7kHz, which would mostly be noise. But as i've now explained at least twice in this thread, there can still be signal above 6kHz, which this kind of filter would ALSO eliminate. In other words: Would it remove the hiss? Of course it would. that's the point. Would it remove signal within that hiss that's above 7kHz? Also yes. Hardware cost for this filter? again, under $10, probably.

-

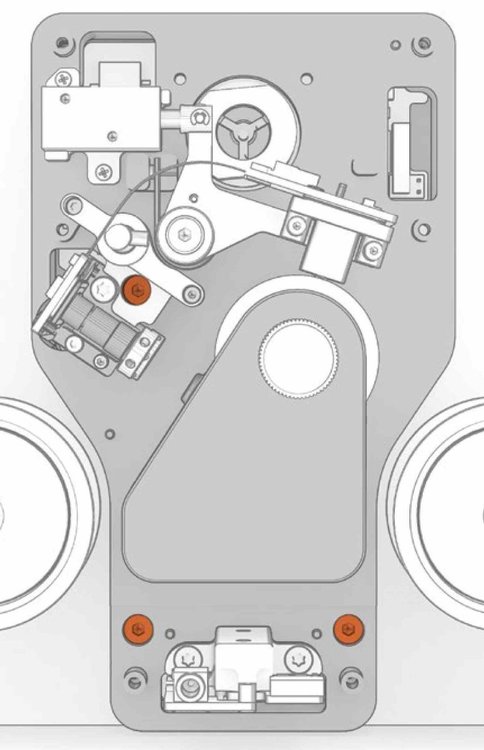

This is incorrect and a quick look at the Cintel manual shows how it works: First, the soundtrack reader and the keykode reader are separate - you thread the film for one or the other through different readers. The optical soundtrack reader is in the upper left. the mag reader is upper right. The keykode reader is on the bottom of the assembly, below the two orange screws. This is all in the manual, from which I took this screenshot. There may be a camera for the optical reader but my guess is that it's using a traditional photocell that's illuminated by the LED shining through the track. This would make sense since that's how other Cintel scanners did it. This is far simpler and cheaper and given the price of this part, it seems more likely.. Another clue is in the specs. The Cintel gives specifications for wow and flutter, which would mainly be a factor in a system where the sound is captured in real-time (or close to it, as the Cintel does) and would be subject to fluctuations in motor speed. A system that uses a line scanner to capture the frames can easily get around this in a couple ways, and wow and flutter isn't much of an issue. If it works like the scanstation, it uses the known position of the film to track and eliminate wow and flutter (see below). Wow and flutter simply aren't an issue on the ScanStation. In our recent tests, the Philips Spirit had major issues with this, due to film shrinkage and the motor constantly struggling to keep up. Again, nobody is saying it's perfect, except you in your straw man arguments... But the ScanStation's method is better. The Lasergraphics reader has a camera that is zoomed in on the soundtrack. The film is wound around a free-spinning chromed drum that effectively flattens the film out while the image of the track is being taken. The image captured by the soundtrack reader uses the edge of the film to align the soundtrack into a perfectly straight line, basically in the same way the scanner does horizontal alignment for Super 8 - using machine vision algorithms to "see" the edge of the film, and make sure the track is precisely placed before any sound is extracted from it. This is far better than any system that relies on rollers alone to guide the film through the reader. And in the case of the cintel, you have to manually adjust using thumbscrews on the outside, to position the reader over the track. Said with such confidence, and yet ...wrong. Keykode numbers are there for us humans. Keykode readers read the burned-in barcodes that correspond to those numbers. We have a $20 USB barcode scanner we use daily for checking in and out customer materials. It's nothing fancy, the technology for that thing has been around for decades, and it's not expensive or exotic hardware. The Cintel uses a completely different reader for keykode, and it's likely a typical laser scanner like you'd have in a supermarket, only smaller, to read the barcode. Reading the numbers wouldn't make any sense. This is not a practical test and won't work the way you assume. In the ScanStation, the position of the film in the scanner is based on the frame (from the end user's perspective), though it is using a closed-loop servo motor which means it knows down to a fraction of a rotation where it is at all times. The current frame is the one in the gate, but that position varies. Because the ScanStation uses a constant motion transport with an oversized gate, and a camera that takes an image of the frame at high speed while it's in motion, the actual position of the film within the camera gate will almost never be in exactly the same place on two passes. This is by design, to allow for shrunken film. Basically, the frame is never in the same place relative to the edges of the gate, on each pass. And that's fine. There is a target location it tries to hit and if there's shrinkage, it may drift from that target one way or another over time. The scanner compensates for that by speeding up and slowing down the motors when necessary, in tiny increments. This affects the speed of the film through the soundtrack reader as well. The optical audio reader, however, is simply reading samples as image of the soundtrack goes by. The drum the film passes over has an encoder, so it knows where it is, and this is correlated with the captured samples so that the fluctuations in motor speed are irrelevant - preventing wow and flutter. But to do the test you're suggesting would only work if you could match the two captured tracks down to the sample, which isn't a simple task. In any case, it's pointless, because as I said above, the soundtrack reader is a better design that ensures that the film is held flat when the soundtrack is read the film edge is tracked to perfectly align the track the encoder in the sound reader is used to correct for any fluctuations in motor speed, eliminating wow and flutter The Cintel is doing what it's doing because by design it's a scanner based on an old telecine model - realtime capture - and everything is optimized for that. Based on the specs they give, I'm pretty certain that it's using a light and a photocell to read the soundtrack. That's why it can only operate within certain speed parameters, and why it needs a specially designed capstan to compensate for wow and flutter. I mean, on the Cintel you have to manually turn dials to adjust the position of the track reader for optimal results, and the film is not being held flat while the track is being read, it's happening in a roughly 6" gap between rollers. That's far from precise.

-

Arriscan film scanner price list / brochure

Perry Paolantonio replied to Daniel D. Teoli Jr.'s topic in Post Production

No. They're incredibly reliable machines. There's probably a lot of back and forth when someone is new to a machine or to an upgrade but once you're up and running, it just works. We've found that we get our questions answered promptly. In the 8 years or so we've had our ScanStation, one thing has broken on it. The replacement cost was reasonable and the turnaround time was quick. -

Wait a minute. You made this about sound quality. In case you forgot, these are your words: "To be fair optical audio off a Lasergraphics is unmitigated shit." But once again, you are comparing apples to oranges. The Cintel sound reader (as I understand it) is essentially what you get in a projector: an exciter bulb and a photocell. Please correct me if I'm wrong. Because if I'm right, you could just as easily say Cintel is overcharging by thousands for $10 in parts.

-

If it were me, I'd believe the person who uses the machine every day. But I'm biased and clearly don't have a clue what I'm talking about. That being said... Here is what it boils down to: The lasergraphics hardware reader captures an audio frequency range of up to 20kHz. This is more than an optical soundtrack can reproduce. Much more than a 16mm optical track can reproduce. The gap between the top end of the frequency range of the signal and the top end of the sound reader, at least for the frequencies within the range of human hearing, will be mostly white noise. "Hiss" is white noise. White noise is random. Film grain is also random. The white noise you hear is the sound of the film grain in the frequency ranges above top end of the signal. In the case of 16mm that means almost everything between 6kHz and 20kHz is white noise. A 16mm soundtrack would have been mixed to cut off the signal above 6kHz because a 16mm optical track projected at 24fps can't reproduce frequencies much higher than 6kHz. 35mm can, in part because the film is moving at a faster speed per second through the machine. If 16mm film ran through the projector at 48fps, it would have a frequency response similar to 35mm. In a projector or a telecine that uses a light and a photocell, there is a hardware low pass filter that cuts off just above the top end of the signal. This removes the hiss above 6kHz resulting in something that is more immediately pleasing to the ear. HOWEVER, it will also remove valid signal above 6kHz, weak as that signal may be. The optical track reader in the Lasergraphics scanner captures the sound at a sampling rate of about 80Khz. It does this by compiling a long, skinny image of the soundtrack, with one line of the image representing a single audio sample, 80,000 times every second. (And unlike traditional optical reproduction, slower speed through the optical reader means better resolution of the image of the soundtrack, because the number of samples is constant - run the film faster and you get fewer samples per given length of film. Run it slower and you get more). In any case, the long strip image is a digital image representing the optical track on the film. This means it sees the grain as well as the signal. And the grain is random. And random grain = white noise. The signal you get from the optical track reader is the same, regardless of whether noise reduction is on. Without noise reduction, you get some white noise from the film grain. With it on, you get the exact same signal without the white noise. because the white noise is the film grain and the film grain is gone (see below) The optical track reader on the scanstation reads the soundtrack while the film is going around a roughly 2" diameter drum. This is a relatively tight radius and has the effect of flattening the film, resulting in a sharper image of the soundtrack, and getting better sound reproduction than a reader in the middle of a straight run of the film, or a picture of an entire frame of film, a la AEO-Light. Lasergraphics Optical Track Noise Reduction: I've spoken at length with Lasergraphics this week about what exactly is happening under the hood here, so this information is from their engineers. I was also incorrect about how they do their noise reduction. When you capture with NR on, they are not applying noise reduction to the captured sound. What they're really doing is grain reduction on the image of the soundtrack *before* the image is converted to an audio file. This removes the white noise caused by the film grain, without affecting the image of the waveform. Thus, the same signal with and without noise reduction, but no white noise (film grain; randomness) on the NR version. We are actively investigating whether we want to start capturing optical audio with the noise reduction on, now that we have this information about how it's doing that noise reduction. We'll likely do a lot of testing on this before making a decision. In the mean time, we will continue to capture as we have been because even though it's capturing some noise (film grain) it's also capturing the full signal. And it's easy enough to remove the noise later if need be. The track reader in the Archivist is different - conceptually, it functions like AEO-light, by looking at the overscanned frame's capture of the soundtrack (however, it is Lasergraphics' implementation, and isn't the same code as AEO-Light). Each frame's length of soundtrack is stitched to the next frame using some overlap, to form a long image that is then decoded into sound. Both AEO-Light and the Archivist software-based sound reader suffer from the same issue: If the film is warped when the image of the film is taken, stitching is harder and you may also get warbling in the sound, due to the out of focus image of the track. Additionally the resolution of the soundtrack in these cases is significantly lower than in the hardware Lasergraphics optical track reader, and is dependent upon the resolution you scanned the picture at. Archivist Software/AEO-Light reader: Let's assume you're scanning a 5k (full overscan) image. Just to make the math easy, let's look at 15 frames of footage, scanned at a speed of 15fps (not relevant here, but is below): That's about 3800 vertical pixels times 15 frames, or 57,000 pixels of soundtrack information per half second of footage. Some of that gets thrown out because it has to be used to overlap with the next frame when stitching so the number would be lower. Figure 200 pixels per frame overlap, and that leaves you with about 54,000 samples per 15 frames. Lasergraphics hardware reader Assuming you scanned at 15fps, that 15 frame length of soundtrack is represented by 80,000 samples (because it took 1 second to go through the hardware reader, at 80,000 samples per second). That is all dedicated to the soundtrack. There is no overlap necessary because it's separate from the image camera. Scan it at 7.5fps (the standard speed for 4k HDR on the ScanStation), and that same 15 frames of soundtrack is represented by 160,000 samples. Based on specs, sound quality, and implementation, the hardware optical reader in the Lasergraphics scanner is gets you better reproduction of an optical soundtrack than a traditional projector/telecine exciter bulb and photocell setup, and in most cases a much better track than is possible with AEO-Light or implementation like it, that are based on scans of the picture+track. (and for Dan Baxter: we tested this on our Scanstation with and without NR, a Philips Shadow HD Telecine across town, and on AEO light. Happy to try other track readers, but we don't have ready access to any)

-

Arriscan film scanner price list / brochure

Perry Paolantonio replied to Daniel D. Teoli Jr.'s topic in Post Production

thanks for clarifying -

Arriscan film scanner price list / brochure

Perry Paolantonio replied to Daniel D. Teoli Jr.'s topic in Post Production

First: No. It's pretty clearly spelled out in the product description in the price sheet you posted. IR requires Infrared lighting. That means there's a hardware component to generate the IR light and some amount of software to output the dust map files (usually mono dpx). So the $18k enables the IR option and has nothing to do with Diamant. The files it generates can be used in any restoration software that works with IR dust maps - MTI, PFClean, Diamant, etc. Diamant is a standalone restoration package made in Germany, that is software only. It looks like for $23k you can by the above mentioned hardware IR stuff, plus you get a special version of Diamant that runs on the Arri's host PC under linux, to automatically do dust removal using the dust maps generated by the scanner. I know reading is hard, but ...really? 16mm Archive Film Gate: $33,670 The thing listed for $370 is (i'm guessing from the description) probably a plate for the takeup reel to keep warped film from telescoping off a core. All of this is written in the price sheet. Using words. In English, even. The lasergraphics warped film gate option is about 1/3 the cost of the Arri gates. You get gates with pressure plates as well as a complete set of special rollers. And if you buy multiple gauges at once the price per gauge drops. So 8mm, 16mm and 35mm gates combined cost *LESS* than the Arri 16mm only gate. -

Why was the Imagica cine' scanner so slow?

Perry Paolantonio replied to Daniel D. Teoli Jr.'s topic in Post Production

haha. that would be amazing. I always thought they were super cool. They were capable of analog video capture (with an add-on card) and didn't cost that much more than a fully tricked out mac with a video board at the time. There was even a version of Premiere that ran on it, I think. I also accept Aaton donations, by the way. No questions asked, you can just leave it at our door. -

Why was the Imagica cine' scanner so slow?

Perry Paolantonio replied to Daniel D. Teoli Jr.'s topic in Post Production

It's from the mid 1990s and it was one of the earliest 4k motion picture film scanners. Everything inside is custom hardware. It uses an ancient SGI 02 machine (I always wanted one of those) to control it. It takes an hour to warm up the lamp before you can start scanning and the lamp only has a lifespan of about 150 hours. This is slow because it's old. It's a monochrome 4k line sensor with a corresponding fiber optic light pipe, which we've discussed here before. The sensor and the slit light are synchronized and both sweep past the film, which is held steady with registration pins. it does this three times - once for each color channel - then combines them into a color image. We just got rid of ours, which was 80% of the way converted into a modern film scanner. It went to someone locally who is going to finish converting it. It's a very nice transport. Originally it was used for scanning short shots of film, not entire films. At the time, nobody did that. This would have been used for grabbing a scene from a film reel probably for visual effects work. The lens inside (a 95mm Printing Nikkor) is worth almost what they're selling it for. The rest, not so much. it's about 400-500lbs of equipment too. Impressive that it's still working though. it's a very complicated machine. The prayer cards inside the door are missing. They're there to ward off evil spirits. It's probably cursed. -

it is. Yes, we agree that we are not audio engineers. Which Is why I consulted one before posting. The *only* assumption I've made is that a sound reproducer that is outputting audio without the hiss is likely doing some level of filtering after the image of the soundtrack is picked up, probably a low-pass filter, but possibly more. This is a reasonable assumption. The hiss is the grain of the film, which manifests as white noise when quantized. The way to get rid of it is to filter it. Some machines do this while capturing. Some machines don't. I'd prefer the former as much as possible, so that we can control it ourselves. To me, that is certainly the better option. Just as capturing a flat scan without grading is a better option. We don't want to bake in any assumptions to the capture. If you would like to keep ignoring what I've been saying, that's fine. But just to reiterate one more time, we would rather capture everything and then tease out the details, then cut off those details when capturing in order to get something that sounds better immediately. That's not a good trade-off, if you ask me.

-

No i'm not. Because I never said that. You keep putting words in my mouth in order to further your argument, as you have done on other forums. Please, show me where I said that. You are doing what you always do - deflecting and ignoring facts. One last time, for the record: I would rather have a scan that captures everything than one that removes stuff while capturing. Scanning the sound a second time on another machine takes a lot longer then applying a filter and rendering out the sound. And with the method we're using, you have the original scan to go back to if you need it for fine tuning. That is a fundamental difference between archival scanning and scanning for quick release of a product on youtube

-

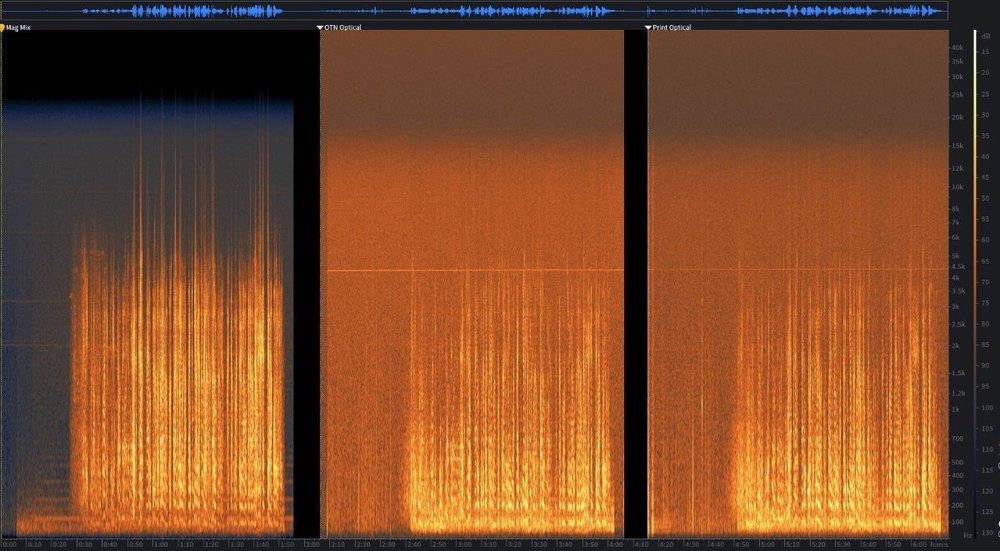

Honestly, Dan.This is the second time you've accused me of something like this (once in a private message on another forum) and it's getting really old, bordering on libel. I use this machine day in and day out. We've run well north of 3 million feet of film through our ScanStation. And you're making claims about things that seem to be primarily based on third-party information rather than first hand experience. I think I'm in a better position to speak about the quality of the audio on this scanner than you. The bottom line is: If you're using an archival film scanner like the Lasergraphics machines, as much as is possible, you don't want the scanner affecting the image or the sound when capturing. I'm not going to argue that the audio from a Sondor is likely to sound better directly off the machine . Of course it is, because it's filtering out that hiss on the film. I do not know what methods it uses, but it's likely (at least in part) a low pass filter, which means it's cutting off any frequencies above a certain value. And that's a very effective way of dealing with the hiss. But it's also a very effective way to remove any signal that might be above that cutoff value as well. If you capture it all, you can fine-tune later to recover that signal. What I have showed you in the image above is the sound captured from a 16mm B/W film that I happened to have the elements for, so we could quickly take a look at what's happening. You can clearly see in the two optical tracks that there is signal above 6kHz. It's not much because it's buried in the hiss. But it's there. A low-pass filter will cut that off and it will be gone. But capturing it gives you the chance to recover that later using other tools. How is that conceptually different a flat scan of the pix with no grading? The whole idea there is to not affect the image when scanning, such that there's as much to work with as possible after you scan. This argument about the lighting on the picture side is a red herring and I'm not going to get into that. Nor have I said this is the case, so I'm not really sure what you're getting at here. It's more about what you do with it (via filtering, etc) than the method of converting the image of sound to an actual sound. Applying noise reduction or a low pass filter during the capture is permanent, and you will never be able to get at the signal that may have been captured, but was filtered out. Once you've done that, it's gone forever. It's fine to run those filters, but after you've captured the sound, where you can see the effect it's having and maximize the signal that's there. A projector is a different thing, with a completely different purpose and a totally different method of capturing the sound. When you project, you are watching the film and hearing the sound immediately. You make a compromise and apply a low pass filter or EQ the audio to get good sound because there is no time to process it more than that. A low pass filter can be implemented in hardware with basically no latency. It's also a 100% analog signal path so yes things like hum from the power supply can manifest in the sound. This isn't a problem with a digital capture of the track, though, so that's kind of irrelevant. But you don't use a scanner to project film, you use a scanner to capture the picture and sound, with the intention of doing more work on it afterwards, in the digital realm. And even so, as I've said above, if what you're looking for is an immediately viewable file from a scanner, you have the option to apply a grade while capturing, and to capture the audio with noise reduction. But we wouldn't do that for an archival scan because it's eliminating data during the capture that can never be recovered. And the scanner you're saying produces terrible audio is an archival scanner, doing what it's supposed to do. It's not a telecine. if you want a graded scan with filtered audio, use a telecine.

-

The Lasergraphics is not "hissy." Your implication with this statement is that it is the scanner that is introducing noise that wasn't there, and this is incorrect. What you are hearing is an accurate representation of the soundtrack as it exists on the film - that white noise is there. It is a part of the soundtrack that has always been there. In an analog playback system (say, theatrical projection), that would get cut out in the sound reproduction path so you wouldn't hear it. But you'd also be losing some information in that process. And as audio isn't my area of expertise and I don't want to be speaking about things I don't know about, I did a test this morning: I captured the 16mm mag mix, the 16mm optical neg and 16mm Print of a short film I made 30 years ago. I sent the files to a friend of mine who is an audio mastering engineer. Here's what we found: On the left you see the mag. This is the mix, which is obviously the cleanest version with the most dynamic range. This mag is a dub of the same mix as the element that was sent to the lab that made the OTN (which in this case was a Nagra tape), so the sound hasn't been compressed into the frequency range required for 16mm audio (about 100Hz-6kHz). That was done by the lab when the Nagra master was played into the optical track recorder. The Track neg and the Print are in the middle and right, respectively. Horizontal axis is time. Vertical axis is frequency. The audio is the same ~2 minutes from the beginning of the film. All three were captured at 24bit/96kHz to WAV files. The brightness of the color indicates the level, and as you can see the optical tracks have brighter backgrounds, which we perceive as hiss. the line at about 5kHz in the optical tracks is an artifact of the Nagra tape (the pilot tone that's reference below). Here's their explanation: In other words, because of the limited frequency range of the optical track, most everything above about 5kHz is noise. And because that's all higher frequency, and because there's little to no signal there, we perceive it as extraneous hiss. The ScanStation is capturing the sound as it exists on the soundtrack, and not processing it further to remove that. As an archival scanner, this is the correct way to do it, and I wouldn't want it to behave differently. If you don't want the hiss to be there in the captured audio, you have the option of applying noise reduction to the capture. We don't do this, because from an archival perspective it's the wrong way to approach this problem. The right way is to do it post-scan, on a copy. Again, I defer to the audio expert for an explanation: This is trivially easy to do even with free software. Resolve has a pretty decent de-noise filter and it does a nice job most of the time with just the default settings. Again, I would ask you to please stop spreading misinformation. The scanner is doing exactly what it's designed to do, and if that isn't what you want, then there is the option of applying noise reduction at the time of scanning. Though, anyone thinking they can use a modern film scanner to create a final product directly off the machine, is using that machine in the wrong way,

-

strange light flicker cause?

Perry Paolantonio replied to lars preisser's topic in General Discussion

haha. it's subtle, but the flicker was definitely there before it was repainted, and gone afterwards! I bet with something like Black 3.0 paint, it would be totally eliminated. Though I'm not sure how well that stuff will stand up over time, since it's more of an artists paint than an industrial paint. -

strange light flicker cause?

Perry Paolantonio replied to lars preisser's topic in General Discussion

Something else to look at: we've had two customers with ACL S16 conversions that had a similar issue. In both cases the problem wasn't a light leak per se, but some of the black paint inside the camera body had been scraped off during the machining. Light was bouncing around inside the camera body, causing reflections that lead to a similar flicker. It's worth taking a look to see if you need to touch up any painted areas. -

That's completely ridiculous, and also untrue. It is in fact, among the best optical soundtrack reproducers currently available. We've had filmmakers who are intimately familiar with their own soundtracks tell us they've never heard their optical tracks sound as good as they do after we've scanned them. Honestly, what is up with you and spewing information about a machine you have apparently never even used? Why do you insist on spreading misinformation like this?