Duncan Brown

Premium Member-

Posts

549 -

Joined

-

Last visited

Everything posted by Duncan Brown

-

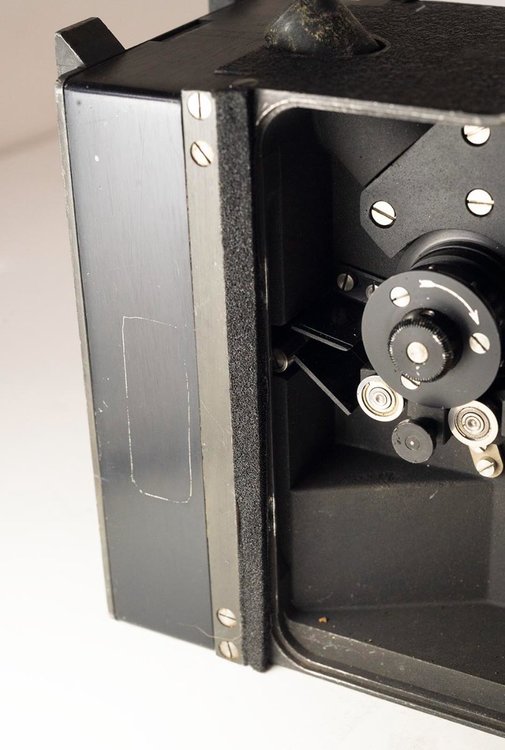

I recently picked up the other, less common, kind of NPR viewfinder so I figure it's time for a thread for all things NPR viewfinder. I'll talk about them, then add all kinds of pictures. First up, the ubiquitous Kinoptik orientable viewfinder. This seems to be on the vast majority of NPRs I see on ebay and elsewhere. I think there's actually a less useful fixed version of the VF but I've never seen one. And of course, since the specs for the mount are identical to the Cinema Products CP-16, and mount made for that would fit too, though the ergonomics might leave something to be desired. The Kinoptic mount can only screw onto the camera one way. There's a little lock lever next to the mount that, when loosened, allows the whole viewfinder to rotate toward the front or back of the camera, a full 360 degrees. There are detents at the most useful positions (every 90 degrees). When the VF is pointed straight back, the image is upright. As you rotate the finder forward, the image starts to spin clockwise, ending up spun 90 degrees for every 90 degrees you rotate the finder. So if you point it straight up, then stand to the VF side of the camera and look down, the image appears upright to you but it's twisted vs reality. If you were to stay behind the camera and look into it, it's on its side. Useful in a pinch with some getting used to it, but mostly you're going to want to keep it pointing straight back (and lock the little lever). With it locked from rotating and pointing straight back, you can spin the more rearward section of the finder to any angle (no detents), also a full 360 degrees. In this case, however, the image orientation does not change - if it's pointing straight back and you rotate it for comfort vs which eye you sue, for instance, the image stays upright. There's a tiny knob near the eyepiece that, when loosened, allows you to make diopter adjustments to match you vision, by spinning the eyepiece. Then you lock it in place again with the little knob. There's a shutter built into the eyepiece. If it's loose, the idea is that it springs into the closed position all on its own, though at this point every one I've seen takes a little help sometimes. Then if you push the eyecup in (with your eye, or with your hands), the shutter springs open and (if all goes well) clicks into the open position and stays there while you film. All in all a respectable little finder, with the caveat that spinning it around in the fore/aft direction makes the image orientation wonky. Some pictures:

-

OK that makes sense, but to a point I think Gregg was getting at, it's kind of unusual to even have an adjustment be so vague. I would expect shims and a spec on backlash or something, not a "kind of move it around until it feels good, or the motor has the least power draw" arrangement. I suspect the one I had was OK when it left the ebay seller, but impacts during shipment allowed it to move. Or perhaps it was the legendary "ACL magazine falls off because you didn't use a clothespin" impact during its last use? But in any event, it's working now, and it all makes sense - nothing inherently wrong with my magazine, and I fixed it the correct way. Duncan

-

That adjustable end cap reminds me of the throttle linkages on my old TR-4 back in the day. Though I think they had a fixed inner cup so that was just to set the friction...and the threaded rod between the links just set the distance between the links. (Not sure why I bring this up, since TR-4 throttle linkages are far too large and heavy for this application!) Duncan

-

The ACL (and, I believe, every other camera on the planet OTHER than the A-Minima) uses B-wind. The A-minima needs more than just A-wind film, it needs those goofy reels. And unless Kodak is supplying it on those reels, it seems pointless to care how the film comes for an A-minima, since you're going to be respooling it onto your own existing A-minima reel anyway, no? The NPR mags can actually be loaded with EI (normal) or EO film. But does that mean it can also be loaded with A-wind film? My brain hurts trying to figure that out, but it's academic in terms of your question, since there are no 200' NPR mags anyway (that I know of). Duncan

-

I have a thread about NPR mags, might as well have one for the ACL too, since I bought a used one that had some issues and took it apart to fix it. The usual disclaimer about NEVER disassembling your gear - leave it to the pros. This is not a how-to guide it's just some pictures I took along the way, that belongs in a thread for discussions of ACL magazine things. One of two 400' mags I bought was jammed - you couldn't turn the thumbwheel in the takeup side of the mag, the drive spigot wouldn't turn. Sometimes it would move a bit, kind of like jumping a gear tooth distance, then it would jam again. So I decided to take it apart. I started inside the takeup side of things and it turns out, for this problem at least, that wasn't required. But it was good to learn how that stuff all goes together. You take off a thin cover plate which exposes the belt a bit, Then you take off the legend plate of the thumbwheel, which also pins in the drive sprocket plate, because the rest of the drive assembly won't come off until you do. Then the whole drive assembly comes out, with two springs in holes that press up against the little pinch roller assemblies. Then you can see the whole drive belt (and where I discovered the mechanism was still just as jammed.) So on to the other side of the mag, where the counters and drive spigot are. Two screws remove the whole counter assembly, and this is one of those parts that goes SPROING when you remove it, as it is actually the thing providing the spring tension on the follower arm. When putting it back together you have to take the legend plate and window off of it to be able to hold the wheel at the right spot, with tension, to get it all back together properly. (If this all makes no sense, then remember what I said about leaving it to the pros!) With that off, I can see the drive assembly cover but the gears are inside it. Taking off the cover with two screws and then the solid machined piece, which also holds the drive spigot, reveals that it's a worm gear in bearings on the spigot and a gear on the back of the thumbwheel. And now everything spins just fine. I clean it up, regrease it, put it back together loosely and everything is still spinning fine. It's not really obvious what was jamming it. I tighten down the screws to the machined piece and... jammed. I loosen it up a bit, notice that there's a tiny bit of play in it. If I shove it down towards the bottom of the mag it's jammed. If I shove it up towards the top of the mag it spins freely. So I push it to that side and crank down on the screws and all is well. NOT a big fan of a design where a piece is loosey-goosey like that, and where, say, a sharp blow (like dropping the mag) would allow things to get jammed. But now I know. (And so do you!) I put everything back together and now it works perfectly. Below are a few pics I took. Note that one of the screws that holds the drive spigot machined holder on is longer than the others! I have a pic where they are lined up with the holes they came out of, for reference. Duncan

-

Eclair Flea Market

Duncan Brown replied to Gregg MacPherson's topic in Marketplace Listings Under $200 / €200

Completely off topic for the flea market thread, but anyone know how hard it is to extract the ground glass from an ACL? The NPR has a little filter slot right below the ground glass that you could always slide something with markings into, in a pinch. Duncan -

Eclair Flea Market

Duncan Brown replied to Gregg MacPherson's topic in Marketplace Listings Under $200 / €200

Wasn't there a whole other cause of flicker that had to do with light sneaking in around the recentered lens mount on a S16 converted camera? I'm sure I read that somewhere around here. But it sounds like you are talking about potential flicker on even a stock ACL. Duncan -

Eclair Flea Market

Duncan Brown replied to Gregg MacPherson's topic in Marketplace Listings Under $200 / €200

Easily fixed with a pencil, I hear! ? Duncan -

Eclair Flea Market

Duncan Brown replied to Gregg MacPherson's topic in Marketplace Listings Under $200 / €200

Well you know me - I assume no access to competent service or parts, and pay bottom-feeder prices accordingly when able. It's weird how all the French cameras have become more quickly orphaned, despite being some top of the line stuff back when they were widely supported. (Don't even get me started on my experiences with Pathe and Beaulieu gear...) Duncan -

Eclair Flea Market

Duncan Brown replied to Gregg MacPherson's topic in Marketplace Listings Under $200 / €200

Well sure, if I were in the market for that camera at that price I would have hit Buy It Now instead of posting it here ? But there are forever people asking for Super 16 Eclairs, so I post them here when I run across them. Duncan -

Eclair Flea Market

Duncan Brown replied to Gregg MacPherson's topic in Marketplace Listings Under $200 / €200

OK, for a less sketchy deal, how about this "Eclair direct descendant" camera package? https://www.ebay.com/itm/325841548465 Aaton LTR54 Super 16, highly accessorized, only $9995 in Los Angeles Duncan -

Eclair Flea Market

Duncan Brown replied to Gregg MacPherson's topic in Marketplace Listings Under $200 / €200

Oh, it goes without saying on any of these listings I link to - Caveat Emptor. I like how he says the conversion "might have been done by Les Bosher" - yeah, because he's well known for modifying the ground glass markings badly, with a pencil? And with his dumb c-pl adapter in the way we can't even see if the lens mount has been shifted (I'm guessing not.) It looks like a 1.5 body to me, but isn't that an ACL 1 viewfinder? Duncan -

Eclair Flea Market

Duncan Brown replied to Gregg MacPherson's topic in Marketplace Listings Under $200 / €200

Another fairly complete nice-looking, heavily accessorized S16-converted ACL setup, this one located in Poland. $7500 or Make Offer. Way too many important details for me to list here, go check out the auction while the link is still good. (Sorry, people reading this thread years down the road!) https://www.ebay.com/itm/285508791395 Duncan -

Replacing the felt band in ARRI 16ST magazines

Duncan Brown replied to Fabian Schreyer's topic in ARRI

My immediate thinking is the same foam used to replace the brittle/gooey mess you find where light seals used to be in SLRs of the era, but let me have a look at one of my magazines when I get a chance. Duncan -

I usually take pictures of everything just so people can follow along but this one went so easily I didn't even bother to get out the camera and lights. I have a 400' French magazine where the size sensing lever was really sticky and basically had to be shoved to move it either direction. I had a hunch what was wrong and it turns out I was correct: behind the engraved metal plate covering the remaining-film dials is a clear plastic piece with an indicator line painted on it. With age and heat, the portion over the core dial had sagged slightly, until it was rubbing quite heavily on the center of the dial. (The spool dial has a center post that sticks up through a hole in the clear plastic, so it is supported better and not as likely to sag.) As happens often in my life, my lifetime hobby of collecting pinball machines informs me of how to fix everything. Sagging plastics are a fact of life with older pins, and there are several effective methods for flattening them out. But in this case, I didn't even need to do that! Just flip the clear plastic over, as it is completely symmetrical in that direction, and put it back together. The indicator line is now painted on the bottom of the plastic instead of the top, but it's just as (poorly) visible as before. The droopy portion now faces up, making it a tiny bit harder to screw the metal plate on top, but that's fine. No more rubbing, lever moves smoothly, easy fix! I will note that when I removed the 4 screws holding this together, one of the side ones was shorter than the other 3, so I made sure to put that back where it came from, but it's also possible someone just grabbed the wrong screw when assembling this; not sure. Does it bug anyone else that the footage dial only goes to 390 when fully retracted? They didn't even paint 400 on the dial! Duncan

-

The smaller platters make complete sense in terms of the instructional stickers not being covered up. I wonder where all those bigger platters I have came from, and why? I could also believe the original lid seals were stiffer rubber, though I have yet to see one that isn't a petrified mess. I think whatever was there was 5mm wide, but I'm using 6mm to get exactly the sort of tight pushback against the lid that you are describing, with the foam I am using. If I can find stiffer material then I could try 5mm wide strips. Duncan

-

Interesting - as I'm working through all these things adding stainless wires and foam, I notice a somewhat random mixture of platter sizes. There are big ones (400'-ish diameter) and smaller ones (200'-ish diameter.) Does it matter? Most mags have one of each, which makes me think one is supposed to go on one side and the other on the other side. If you put the big one on the feed side, you can no longer read the EI/EO feed arrows so it seems like that side should always have a small one. But what a weird reason to have a platter smaller than the film going on it: so you can see a sticker. It makes total sense to have a big one on the takeup side, if you want 400' of film to take up tightly there. But there's a sticker on that side that gets covered up with the big platter too. Most of these (old, heavily used) mags have wear marks at both diameters on both sides so that's no help. I can't find any clues in the NPR manuals either. Weird. Duncan

-

Ah, good point! Keep light out, keep sound in. I haven't yet had to replace any of the three sound deadening pads inside each of the mag doors, though I did have to Pliobond a few back into place. Thankfully they seem to hold up OK. Dynamat would probably do the trick as a replacement but it's hellishly expensive. Duncan

-

Then there is the front edge of the compartments. Most of my mags have foam which looks just the like stuff on the face: hard, tired, no longer performing any function. Some have foam that has been replaced with clearly non-factory foam. But some are clean as a whistle, clearly having never had foam there ever. Was this a running change Eclair made? Or is all the foam I'm seeing there the result of technicians adding it over the years? Anyone know? In any event, it seems like a worthwhile idea, and it's much easier than fitting foam into slots. I used 3mm thick foam and cut it into strips 6mm wide. Drop it into place up against the front mounting block at the mag opening (one on each side of the mag) and cut it to length and you're good to go. First picture is some nasty crumbling replacement foam that certainly didn't come from Eclair. Second picture is one of the mags that clearly never had any foam. Next is my new foam strip installed with an open mag for comparison to the other pictures. And lastly is a picture showing how it smartly fills the gap there and prevents any possibility of light sneaking in that way. Duncan

-

Next up: foam. If you've owned old still cameras, you're familiar with light-sealing foam which crumbles or turns to greasy goo. NPR mags did not escape this fate, though it's easier to overlook (and then wonder where the light is sneaking in.) First, the face of the mags has a die-cut rectangle of foam in a groove, meant to keep light from sneaking in to the film/gate after mounting the mag. All of the mags I have, have at the very least flattened-out foam which is no longer guaranteed to fill any gaps between the mag and camera. Some of them have even worse: crumbling/missing chunks of foam. What follows are three pictures. One of a typical used mag with tired flat foam. The next is one where I've removed the foam to show the channel it fits in to. (This particular one had some weird replacement foam that was attached using some glue that turned very hard and stubborn over the years, thus the overall nasty look to things. Normally the channel looks a lot cleaner than that.) And last is a magazine where I replaced the foam, inexpertly but good enough. (I'll get better as I do more.) After cleaning the old foam out with an orangewood stick, I cut some 2.5mm thick foam into 4mm wide strips, then cut the strips down to length and carefully set them into the channels, using the orangewood sticks again to gently press them into place. They have adhesive backing, so you just get them lined up then carefully press them home. 2.5mm was my best guess as to the original thickness but if you just wanted to get all 3mm thick foam that would probably work just fine here too. I got an assortment of thicknesses on amazon.com but it's available lots of places. I got it in sheets that I then cut strips out of with an exceedingly sharp razor blade. I don't have a die-cutter to make rectangles so I did the long sides first then cut the strips to fit between those sides. Duncan

-

Eclair Flea Market

Duncan Brown replied to Gregg MacPherson's topic in Marketplace Listings Under $200 / €200

Give us here first shot at it ? Duncan -

Eclair Flea Market

Duncan Brown replied to Gregg MacPherson's topic in Marketplace Listings Under $200 / €200

He dropped the price to $2000. If I didn't already have two very nice NPR motors I'd probably buy this just for the cool motor alone! Duncan -

Eclair Flea Market

Duncan Brown replied to Gregg MacPherson's topic in Marketplace Listings Under $200 / €200

I think your near-unicorn ACLII S16 kit was definitely a fair price, but I would be even more brutal with discounting other kits for sale. Can you even get a S16 conversion done on an ACL any more? And as always, no matter how shiny and seemingly unused one of these ebay deals is, especially when coming from an absolutely clueless seller (as most of them are), you just never know what expensive/fatal surprises await you when you receive it. I much prefer to pay parts-camera prices and be pleasantly surprised when it mostly works, than to pay market prices and end up with a very expensive doorstop. (I'm too broke to pay fair prices for fantastic rigs like yours; I can only play in the pig-in-a-poke market...) Duncan -

Eclair Flea Market

Duncan Brown replied to Gregg MacPherson's topic in Marketplace Listings Under $200 / €200

Another probably-overpriced-but-certainly-appealing NPR kit on ebay in LA. Perfectone Compact (crystal sync) motor, Angenieux viewfinder, Bernie-brightened screen (just regular-16 though), 3 400-foot magazines with two covers, standard C- and Cameflex mounts, but with the Arri-B adapter with setscrews that lets it take Arri-S lenses. Says it works great, but no battery or cable in evidence, so there's that. $3600 or Make Offer. https://www.ebay.com/itm/325780641216?hash=item4bda0a15c0 Duncan