Andrew Wise

Basic Member-

Posts

52 -

Joined

-

Last visited

Everything posted by Andrew Wise

-

I’ve seen this same thing, someone told me it was a wax they applied to the film after processing. But I’m not sure if they were guessing or speaking from first hand knowledge.

-

Film Restoration - Magenta/purple dye transferred to film base

Andrew Wise replied to Andrew Wise's topic in Post Production

Thanks for the info, that’s really interesting to hear. Good to know about that to keep an eye out for it. I’m really not sure if anything was used on this film, the other films in the collection didn’t have the same issue, although they were different stocks, and could have been stored elsewhere and treated different before they came together. -

Developing old Fuji Single8 R25 and RT200 films

Andrew Wise replied to Pilvari Pirtola's topic in Film Stocks & Processing

I’ve developed fujichrome r25 in ecn2 and tried a reversal process using b&w as first dev, then ecn2 as 2nd dev. Both worked ok. the remjet is particularly bad, it comes off as flakes and strings, it sticks all over the rest of the film and gets stuck in the emulsion. I used a lomo tank, and I couldn’t fine a way to wash it off successfully. -

Film Restoration - Magenta/purple dye transferred to film base

Andrew Wise replied to Andrew Wise's topic in Post Production

Thanks for all the replies and advice everyone. Thanks Bob, I used the filmfabriek here so I could push the RGB light source, I balanced it to be peak white. I've tried some colouring in resolve but I'm not that skilled, and it just takes away from the other colour of the film. I took some of the leader where the dye had also pressed into it, I couldn't get it out with any alcohol (iso and ethanol) and water. But it could be different to the film base. I could try steal some from the tail. It might be something I just have to leave as is. Just do the best scan I can. Maybe someone down the track can do some further work on the files -

Film Restoration - Magenta/purple dye transferred to film base

Andrew Wise replied to Andrew Wise's topic in Post Production

Unfortunately it’s not just the standard magenta fade that you’d normally see which I can correct, It’s magenta ghosting from the frame that was rolled on top of it in the wind. here’s an example - https://app.frame.io/f/df4571a5-c6a7-40f1-a81f-d48e8f0d563c a friend told me it could be from a tight wind, or maybe film cleaners or lubricants used in the past. -

Hi all, I have some 16mm film with signs of vinegar syndrome, mostly just smell. But it was stored in a can with another film with full blown VS. I’m not 100% sure on the correct word to use, but I believe it’s Ferrotyping? It seems the emulsion has leached some dye, and it’s become pressed into the base. It doesn’t come out with alcohol or water. it’s only purple/magenta in colour. the film still seems to have ok colour going on. its marked as Kodachrome on the film edge. it’s the first time I’ve seen this before. Is there any fix either chemically or in post? thanks!

-

Yeah thats why I keep the horizontal stabilisation off, luckily the gate on the first gen Pictor has two sprung fingers to keep it against the edge which work quite well.

-

That’s another one of my uploads, same YouTube channel. From memory I may have applied translation stabilisation in resolve to that clip to take out the handheld shake. I’m not sure Dan has a scanning company, But no, the place I was talking about that did a transfer on that same film before I did, is quite an old business here in Australia that has been doing it for a while. But they are still using the same old equipment, giving people SD only transfers. They were the best once upon a time, but just haven’t upgraded the machines and workflow as scanners improved.

-

Nothing wrong with the HDS camera, what I mean is when looking at the quality of a lot of 8mm that I scan, I can’t always see much of a different scanning in 4K vs 1080p on the Pictor. There are some films that I can see the difference, quite often actually standard 8 film, I guess the better gate design and prime lenses - I don’t know. And of course there is nothing wrong with scanning at 4K, and in a sense it is nicer to have it play on a 4K monitor. That film was not stabilised in post, but it was stabilised in real time from the scanner software, you can either choose to stabilise vertical, horizontal, or both. I choose vertical only because as we know now the sprocket hole on s8 likes to dance around horizontally.

-

I have the first gen launch Pictor, 1080p but with a sound head and the Ricoh lens. I DIY changed it for the schneider kreuznach current lens. (it’s not a quick swap). The build quality of the machine is excellent, I got to see it all when I pulled it apart to see the lens. The Pictor is an awesome little scanner, and would buy another if I needed. The Pictor pro with the slight resolution bump is temping, but 1080p works very well for 8mm I’ve found when comparing against 4K scans I’ve done on the HDS. Software is easy to use, all the options you need are there and straightforward. it will stabilise the image in real time tracking the sprocket hole, similar to Lasergraphics (so I believe, haven’t used one). it works very well to avoid those bumps at splices too. the sound option is very nice, on mine I can capture real time 18 or 24fps as an uncompressed AVI. Occasionally I’ll get a dropped frame, but I’m using a little HP omen laptop which probably can’t keep up. you use the companion software FFtranscode to transcode to ProRes or other codecs while it also applies the audio sync and offset. id normally scan at around 8fps as a DPX sequence so I can use the wetgate and allow it to dry. I’ve been temped to just extend out the film path with some more rollers to allow faster scan speeds with a longer drying path. the light source is more than bright enough, something that irritated me about a different brand I had. And being RGB you can tune it to the film. The colours straight from the scanner are ok, but they do need a tweak to get it right. I worked out a preset for the gamma levels that I always run, and I have a lut that I now drop on the files to correct them. If you ever get one, I’m happy to share that with you. Support from FilmFabriek is good, they reply to my emails same day and will log on remotely if need be. But I’ve never needed support on the Pictor, it’s worked perfectly. I only needed support on the HDS after I changed the camera to get it setup. feel free to ask any questions if I didn’t cover anything. I’ve only got one video uploaded that I scanned on the Pictor Pictor scan example

-

Anyone try the Lasergraphics Archivist scanner?

Andrew Wise replied to Daniel D. Teoli Jr.'s topic in Post Production

As for the standard gate, is it flat also? or does it have a slight curve in it to keep the film running on the edges? -

Anyone try the Lasergraphics Archivist scanner?

Andrew Wise replied to Daniel D. Teoli Jr.'s topic in Post Production

What does the archival/shrunk film gate on the scanstation/archivist look like? And any feedback on how it performs? -

How to work with moisture affected sound film

Andrew Wise replied to Andrew Wise's topic in Post Production

I think it was, local TV station story. It’s positive film -

Epson V850 and DI Style Log Scanning

Andrew Wise replied to Dan Finlayson's topic in Post Production

I’ve had issues with scanning home developed ecn2 vision 3 on the epson v850. I find it impossible to get the right colours, I tend to use a b&w profile. No matter what I do, it still wants to do some auto control. But I’m not a silverfast expert. My uneducated guess and future plan would be to use a DSLR/mirrorless with macro on a copy stand, photograph it and then invert negative in resolve. I’ve experimented using my little aputure MC RBG light as a backlight. You can push it to a blue hue to compensate for the orange mask which is quite cool. I have considered making a little 3D printed neg holder with diffuser to sit over the aputure MC, under the copy stand. -

Hi all, as the title suggests, I’ve received some 16mm colour film with a magnetic sound stripe. it’s a tv reel, a field interview. it seems they kept the box in quite a wet area as there’s a lot of rust on the reels. The film is lightly stuck together, enough that it can be unwound without affecting the emulsion, but unfortunately if it’s unwound the magnetic sound strip will come off, sticking on the other side it was pressed against. I only unwound about 20cm before putting it back to find advice on how to proceed. thank you!

-

16mm transfer options in Australia?

Andrew Wise replied to Patrick Cooper's topic in Post Production

Memorylab do excellent scans, but most labs will only provide you a flat file unless you ask for something else. you’d need to take the footage into resolve and push the footage how you like. -

I’m slowly improving my hand processing using a lomo tank, but the one thing that’s still visible are occasional water marks. also, hanging up to dry takes days. Does anyone have any suggestions? I’m doing the final rinse using distilled water with Kodak photoflo, but they still appear. My solutions are also made with distilled water. But I do rinse the film between steps with tap water. (Maybe this is bad?) I was thinking about making the tail end of a processing machine, the dryer. I was thinking about an acrylic enclosure with the standard long racks to transport the film within the cabinet, keeping it in the warm air for around 7 mins or so. I’m not processing much, only 100ft at max, so I could probably pull it into the enclosure with some leader already laced up, and once all the film was in the enclosure, it could move dead slowly within just to avoid sitting on the rollers for too long before entering the enclosure, I wanted to add an air knife to shoot off the water, particularly what’s held around the sprocket holes. This is always the source of water marks for me… I use some squeegee tongs, but water hides in the sprockets and then creeps out. I was wondering if anyone had any recommendations for off the shelf air knives they’ve seen used in film processors? I have a nice quiet Chicago air compressor here i can hook it up to. Also, if you think my idea is way too over the top, and I should just buy a hanging film heater. You can say that too… I’m just a bit over excited to make things.

-

Kodak Vision 3 & Color Chart funky colours

Andrew Wise replied to Boris Kalaidjiev's topic in Film Stocks & Processing

What’s the incentive to cross process it? I just don’t understand the appeal when we have such a variety of negative stocks. (I’m only very new to shooting film) -

Macbeth colorchecker filmed on Kodachrome

Andrew Wise replied to Andrew Wise's topic in Film Stocks & Processing

Thanks for all the input. I thought it was a very very long shot! I once scanned someone’s fathers 8mm where he had shot a variety of focus charts from some amateur photography magazine. I made me curious if someone had gone so far to shoot a Color chart. But you’re right, why would they think they needed to! i did manage to buy an it8 Kodachrome slide on eBay. -

Thanks Richard. I did a google search using soft touch rollers and came across this site JJ Short but they appear to be rubber, and a pretty dated site. Silicone would be much nicer ? the 3D printing doesn’t really leave the nicest surface even after sanding. I find on the loop where the edge of the emulsion is contacting the roller, if it tracks sideways slightly it will rub a slither of emulsion off. It’s far from the image area so not an issue, but just gets stuck on the mohair paint roller. I was hoping that I could use the soft touch rollers, but maybe they were not intended for touching the emulsion. Maybe I’d be best to find someone to make some up on a lathe with a very smooth surface.

-

Kodak Vision 3 & Color Chart funky colours

Andrew Wise replied to Boris Kalaidjiev's topic in Film Stocks & Processing

It was E6, tetenal kit at home, so variable/depending on my skill lol -

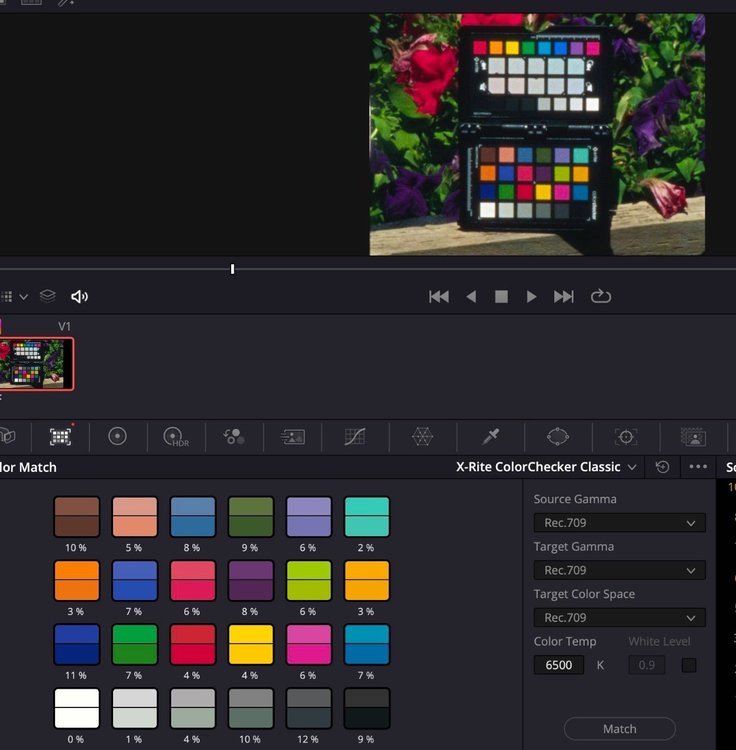

Kodak Vision 3 & Color Chart funky colours

Andrew Wise replied to Boris Kalaidjiev's topic in Film Stocks & Processing

This was ektachrome BTW. I'll have to give vision3 another go -

Kodak Vision 3 & Color Chart funky colours

Andrew Wise replied to Boris Kalaidjiev's topic in Film Stocks & Processing

I've got it working close to where it should be, but still not perfect. I scanned something at a high gamma level of 2.4, then chose rec709 for all the 3 options. It still made it contrasty and a little saturated. But it's on the right track! -

I've made a little jig for helping wipe off remjet after hand processing film in a lomo. The rollers I'm using are 3D printed, contacting the film by just the edge. But I'm curious about the foam rollers used in processing machines. They look like a shrunk down version of one of those foam rollers people use under their back, with all the little bumps. Or a paint roller designed to give texture. does anyone know of an off the shelf product I could cut down?