Gregg MacPherson

Premium Member-

Posts

2,628 -

Joined

-

Last visited

Everything posted by Gregg MacPherson

-

Which ACL viewfinder are you refering to? I know of 5 different designs. I've looked through 4. The early Ang. ones on the ACL are a smaller image and maybe not as bright as an SR1, but there was nothing about it that one would have called horrible in it's day, relative to it's peers. The big fully orientable Kinoptik is a big bright, sharp image. I don't have other cameras here to compare, so unlike you, I will not pretend to know more than I do... And again, with this pretending to know ACL intimately and having serviced them. Define "serviced". How many movements have you had out of the body, and what did you do to them....? Now define "countless". Rhetorical questions really. And while I'm in the mood to complain, how about editing yourself Tyler. Write less but more meaningful words.

-

Heroic effort David! Sorry I haven't been able to read all the thread. But I noticed this comment, and having just recently looked at some 1980 prices and 2022/1980 dollar value, I wanted to add something. In 1980 an Eclair ACL II with best Vf, motor, two mags, basic accessories and no lens, was USD21950 (2022 value USD75580). The first LTRs that came to NZ I was told at the time were USD18000, but that might have been strategic pricing. These cameras were, roughly speaking, mass produced. Without scale, the manufacturing costs will rise. Making mechanical parts in China, in even small runs, the costs will lower. Maybe, as speculated already, shifting to electronic rather than mechanical means to achieve some functions, should save cost. Can't miss a chance to upvote for optical VFs. An electronic VF is a really unappealing idea. Was someone on here slagging off about oscillating mirrors when critiquing the new Logmar S16. We've heard this nonsense before. Probably someone pretending to be a mechanical design engineer....It can be easily observed from the ACL, that oscillating mirrors can reduce the bulk of the camera body and can be very quiet. Note that the mirror Hz is half the camera fps. Sigh, whaddaya gonna do. No more down voting allowed. Gregg.

-

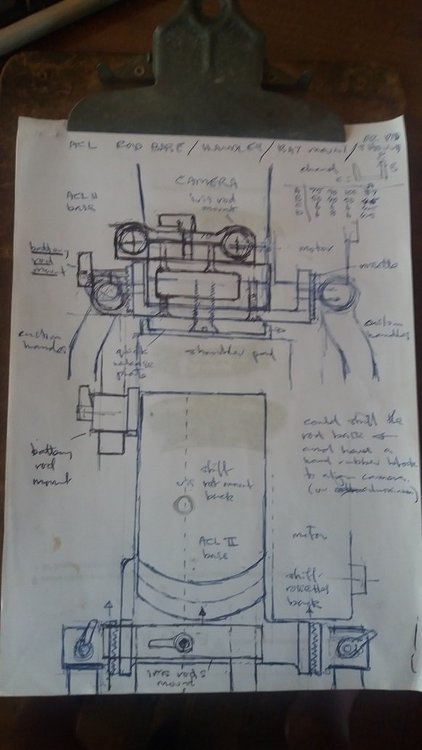

Mostly done on drawings for an integrated base. Hope these pdfs will open. Some version of this looks easy to make. The Chinese fittings are not an accurate drawing of available parts, but useful as is. If I finish and settle on some fittings I will specify. Does anyone know if all the Chinese "Arri standard rosettes" out there actually fit each other..? The handles shown are just bent alloy tube. You can buy Smallrig handle sets that will fit on the rossettes. Still pondering the torque if we have battery and shoulder pad offsets. Maybe a single 19mm rod or square rod. For some reason double rods to the rear just for shoulder pad and battery is really unappealing. I'd rather go back to a 19mm rod base and fix all to that. The common practice of putting a handle set on onto LW 15mm rods may be ok for light cameras, but I think is unworkable for ACL, at least for ACL II. The vertical offset from base to rods raises stress, so a stronger machined part would be needed. Also, it is trickey getting the follow focus far enough back to reach the prime lens gear on ACL. The rod mount part(s) take up space and you need to leave room for access to the run switch on the body. Shifting a handle mount further forward will add more stress to the rod mount and rods. If these pdfs aren't reachable I will try something else. Gregg base plate 5 et al.pdf base plate 5 no camera.pdf

-

UPDATE: ACL techs, Service data, Manuals and Sourcing parts... Please edit and use the bold type headline above for updates. If this thread gets long or confusing it might be useful to post an update now and again rather than having people speed reading pages and trying to interpret...So if anyone is keeping up to date and has the urge... Though the inquisition on the fate of the Arts Media parts may warrant a separate thread...Ha. Gregg.

-

Without knowing the form of your motor I wasn't suggesting mounting directly to the camera body with the four inner screws. Just wondering if the three screw locations on the small motor mount are an option. If needing the bigger radius of the big outer plate, then those with ACL Is will find the plate probably. VP had them about 5 years ago, probably still do. A few years ago, before (Gerard?) at Arts Media disappeared, I was selling him a lens and he offered me to quickly harvest a stash of parts. To my profound regret I did not act. I wish I had somehow helped to find them all homes that would make them accessible. Gregg.

-

I was wondering if the vertical dimensions of the big multispeed motor might be ok constraints for Aapo's design. But the bottom of the motor is close to being in plane with the bottom of the base on an ACL 1.5, so I'm thinking a riser plate would be needed on an ACL I base. Not a real problem. Regarding the motor mounting plates. An ACL II (and a 1.5 may be same) has a small inner mounting plate that I think fits the small motor, and a larger mounting plate that fits over that and screws to it. The big motor fits that. Would be good to know if the French inner mounting plate is the same as the English one. It's the inner plate that has the screwed connection to the camera. So, thinking of accidents, bumps, there may not be much advantage in retaining the big mounting plate. Big plate might make motor alignment easier if you have limitations in accuracy of the machined mating face on the motor body. Gregg.

-

Eclair ACL 1.5 newbie questions (with pictures!)

Gregg MacPherson replied to Duncan Brown's topic in Eclair

I know the feeling. He repaired a video assist for me so that helped me feel ok asking questions about other stuff. -

Hey Aapo, Any chance of a thread on progress with the ACL motor? You could keep the postings short. Too late to take votes on the ideas? My vote is for... - A form similar to the Aaton LTR/XTR motor, with a small box extending from the motor housing to the rear, and an XLR-4 connector at the lower rear of that - Replicate the Lemo on the camera base that powers the AZSpectrum video assist. Don't know what else that does. - Speeds we have now are ok, but if it didn't add cost, more would be better. - Single frame capable. - Mirror parking. I wouldn't care if it didn't have it, but most people will want it. - I'm sure you have ideas on the LCD display for speed, battery V and footage counter already. Footage counter would be good, as only the English mag is really explicit, and also, the common video assist obscures the mag footage counter. Here's to elegant laziness yielding a simple, robust design. Gregg. PS..Edit..I didn't get the last joke.."Just a thought if someone finds it overly difficult to deal with the original design of the camera..."

-

Eclair ACL 1.5 newbie questions (with pictures!)

Gregg MacPherson replied to Duncan Brown's topic in Eclair

Duncan, Give Andrew at AZSpectrum a call or email, show him the video, you might get some free advice or some idea on cost if he diagnosed or repaired it. I've found him really approachable and helpful. You will find a spare motor if you are patient. I have one here that I am considering selling (mirror parking model). No idea what they are worth now. Ebay sold value could tell us, but after 5 years selling hiatus I am treated like a new seller with limit of 3 items and $200 total listings per month. And squeezed from Paypal towards Payoneer, with a bizzare barrage of security checks. Gregg. -

Not many, if any options back then. The Arri 4x4 was bigger, heavier and no way could I afford it. No internet to go looking for obscure third party providers, and no Chinese manufacturing revolution yet. The Britten brothers, famous for the motorcycle, rented an Arri matte box for the weekend and copied it. Those were the days. The MB shown above has a good long bellows. It's a side loading 3x3. No trays, just slide straight in. I never got around to finishing it, it needed a latch of some kind to keep the side door closed and needed a donut I designed and made patterns for all the castings. The whole thing is very light and didn't affect the balance much when hand holding using primes. Gregg.

-

There are cheap V mount mounting plates with 15mm rods clamp. Using one rod only the torque due to gravity may be fine with the batt offset behind the mag, or one may need a pin or set screw with detent. The aluminum tube may bend if it gets a big bump, but that's a good thing, taking energy, and being cheap to replace... Square rod is nice for this kind of problem, but it's a lot of work making the clamps/fittings without the right tools. And using solid square aluminum rod will put big loads on the clamp on the rod base... Re making square holes, witness this slightly masochistic exercise, machined with a drill and file....(40years ago...!) Gregg

-

Eclair ACL 1.5 newbie questions (with pictures!)

Gregg MacPherson replied to Duncan Brown's topic in Eclair

The wings on the metal bodied connectors should grind ok shouldn't they. Will take a steady nerve and some care, skill (I take no responsibility if it doesn't work) Gregg. -

Eclair ACL 1.5 newbie questions (with pictures!)

Gregg MacPherson replied to Duncan Brown's topic in Eclair

Am I understanding you correctly...You just made joins in the wires rather than take the tails of the new connector all the way to the original destination. That's the way I first thought of doing it, then I wondered if there was any reason not to. One of the guys at Panavision Auckand was going to charge NZD300 labor to replace the connector on a camera body, which made me wonder if he was going to do it the harder way. I never asked. Gregg. -

Eclair ACL 1.5 newbie questions (with pictures!)

Gregg MacPherson replied to Duncan Brown's topic in Eclair

Heikki, Did you replace the connector yourself? What was that like to do? Difficult? Gregg. -

Eclair ACL 1.5 newbie questions (with pictures!)

Gregg MacPherson replied to Duncan Brown's topic in Eclair

For the Jaeger, did you try Jean Louis Seguin? He may have some old stock or some ideas. The original plastic cannon 9 pin, with tails, I have got from VP before, was $25 then, they probably still have. But if the metal body ones are interchangeable it's worth the money. Gregg. -

In the idea in my sketch the camera base can snug right into the corner of the C section aluminum. Just need to mill or file out the corner radius. The vertical for the RH rossette is forward of that so the corner radius remains there. Battery rod mount should be less stressed so a had corner may be ok there. With the battery rod mount, sofar all I was doing was trying to improve the mass distribution of the camera, shifting the batt to the rear. It could go all the way to the back of the mag. I never used any of the modern battery systems so I don't know what they require, but one could design a small generalised mounting fitting or plate that clamped onto the battery rod, and tucked around the back of the mag. Then whatever generic or ad hoc battery mounts required could screw to that. If the battery rod/mount idea can be a single rod and cope ok with the torque on the rod due to the offset battery position, good. Other battery positions possible, like beside the mag, but as far back as pos. In that case the mass distribution, L R wise, is same as with the normal onboard battery.

-

Second thoughts, the rod mount won't hide the cannon 9 pin connector. No problem, it will just have a protective cover screwed to the camera body.. The sketch shows a rod base made from a 100x40x6mm C section. A smaller than 100mm width is possible. Just saw some 80x40x6mm rect section in the catalogue. When one looks at the side elevation (can show later) there is room to shift the rosettes and iris rod clamp rearward. The LH rossette sneaks under the motor a bit. Gregg.

-

Duncan's ACL 1.5 "show and tell" reminded me of ideas percolating on an integrated iris rod, handles, battery and shoulder pad mount system for ACL. I had a fun idea a while ago that was conceived with a casting with 19mm rod mounts giving the handle mounts. But that's a lot of work unless one has skills and a mill to machine the casting. So the current idea is just conceived as being cut from an aluminum angle section or C section. Single handle version... An aluminum angle with a vertical face on the RH side. Chinese rossette for a side handle. 9 pin cannon connection safely hidden behind vertical face. Chinese 15mm iris rod clamps screwed to a riser at the front of the horizontal face. The two handle version... An aluminum C section so you have vertical faces on left and right sides of camera, rossettes each side for handles. Same 15mm iris rod clamp idea. A single rod clamp at the right rear for battery mount options. The ideas that I thought about before beginning the exercise. - All load taken through the 3/8" mount under the camera base. - The hand held rig will fit straight onto a tripod. - Maybe a shoulder pad can fit to the quick release plate. - Need good access to the original switch even if switching with the 9 pin cannon on the RH side. - Rod mount must be close enough to the body so that follow focus can reach prime lenses. - Develop some extension to the rear that allows battery position to the rear. Maybe a single rod offset from the mag. The sketch below shows the ACL II version. If I get a chance I will make an an AUTOCAD drawing so these are easy to make Cheers, Gregg.

-

Eclair ACL 1.5 newbie questions (with pictures!)

Gregg MacPherson replied to Duncan Brown's topic in Eclair

Just thought how easy it would be to make up a rod base with handle mount(s) for your 1.5. All load taken through the 3/8" mount under the camera base. I prefer to do my thinking with drawings rather than thinking out loud but.... An aluminum angle with a vertical face on the RH side. Chinese rossette for a side handle. 9 pin cannon connection safely hidden behind vertical face. Chinese15mm rod clamps screwed to the front of the horizontal face. The two handle version. An aluminum C section so you have vertical faces on left and right sides of camera, so a rossette each side. Same 15mm rod clamp idea. One needs to look carefully at the drawings or model first, but some people just do, fiddle, play, refine... The ideas that I thought about before on this type exercise. - The hand held rig will fit straight onto a tripod. - Maybe a shoulder pad can fit to the quick release plate. - Need good access to the original switch even if switching with the 9 pin cannon on the RH side. - Rod mount must be close enough to the body so that follow focus can reach prime lenses. - Develop some extension to the rear that allows battery position to the rear. Maybe a single rod offset from the mag. Cheers, Gregg. -

Eclair ACL 1.5 newbie questions (with pictures!)

Gregg MacPherson replied to Duncan Brown's topic in Eclair

I'm thinking the tape spacers offset the motor a tiny bit, allowing motor mounting screws to adjust the motor/camera alignment for noise. The tape may have lost it's thickness dimension and elasticity so the exercise might have to be repeated. The differences in thickness of the various original spacer offsets may have been very small, hard to measure, but I would be curious and lay a rule between spacers and vernier down to the motor mount plate. Without carefully measuring, roughly how thick are the spacers? There is a faint chance that someone offset the motor to make it easier to press the drive pins into the rubber rather than align to the holes. Quelle horreur..! Or maybe the rubber block was non standard dimension. Probably you will just remove the spacers and see what the natural motor alignment feels like. Maybe someone can measure a rubber block for you if you want to check yours. When mounting motors be really careful and gentle. The drive pins and holes in the rubber block you can align just by eye to some arbitrary axis and they will slot in. The original plastic 9 pin cannon connectors need care when fitting the motor. You hold the motor offset in correct position and gently wiggle till the connector and drive pins slot into place. Were you able to test the rotary speed selector switch? Gregg -

Eclair ACL 1.5 newbie questions (with pictures!)

Gregg MacPherson replied to Duncan Brown's topic in Eclair

Duncan, Show and tell time, that's what they called it at my son's kindergarten (pre school). I wonder what the weight is down to with the small base and the orientable Ang viewfinder. The ACLII with big base, big motor, big Kinoptik viewfinder, video tap, ergonomic handle and battery gets heavy, like an SR, even without a zoom. The ACL I with small motor, early Ang viewfinder, zoom with battery on your belt was really light on your shoulder and nimble. If you have separate battery and are plugging/unplugging a lot with hand holding then the XLR-4 would be better at that. I'm not a fan of on board batteries, not at the weight of NiCad/NiMhi. Maybe a Lithium Ion batt is light enough. The other issue is the fore and aft mass distribution of the camera on your shoulder. Even with a prime, it's a bit front heavy, and I always dream up ways to shift the battery to the rear. So a design opportunity I think, maybe integrating rod base, handle, battery support, shoulder pad. I tried to read everything and make some notes... - I didn't understand your observation that "..the film loop comes back into the feed side of the magazine, and passes through to the takeup side internally..". It just takes an oblique path through the dividing wall, from feed to take up....Moving on. If it's a while since CLA, it doesn't hurt to take the light traps off and check for dust etc. While there check that all the rollers feel super light and free. - The Jaeger connectors on the camera get a lot of wear and tear and stress (this is less important if you aren't using it a lot). The Jaeger connector on the cable, even worse. Having the Cannon (XLR-4) on the camera like on the ACL II is a better idea (the II has the camera and battery connectors switched). On the ACLI there didn't look like there was enough depth in the base castings to do it. If the 1.5 is maybe deeper and you can do it..? Generic XLR-4 connectors are quite cheap. I gather you are good with small fiddley soldering etc. Soldering/fitting the Jaeger I found trickey, but my skills in that department are meagre. Cannon (XLR-4) is pretty easy. - The sliding run switch does feel odd at first, you get used to it. On my ACL I I had a custom double handle casting pointing to the front and it was easy to start the camera with my thumb while hand holding. The original bottom handle I don't like much. The factory ergonomic handle is really nice but give not enough position options for good hand holding. So there's some freedom to explore useful options for design of front/side handle/rods...I've seen pics of a custom made handle that fixed near the end of a rod that extended forwards, downwards 400mm at about 45deg. If using a ready made two handle set that fits to a 15mm rod set, I think some rod base designs may not be strong enough for the weight of the ACL at the rod, base connection. The little handle mounting module on the RH side that you are missing has a rossette that is a good mount for handles. It's attached to the camera with two small screws. I think the engineers think like aero engineers, applying load cases to find critical loads, and allowing for limit loads and failure loads. The result is very small screws, that may not be big enough for the modifications, adaptions and accessories that third parties apply. - The availability of components (motors, viewfinders etc) maybe comes in waves. Five or ten years ago there were quite a few components on eBay. If the weird prices from camera brokers make it hard to know what things are worth. - What's with the custom tape spacers on the motor to body connection? Was someone trying to adjust the noise level that way. Some people do it by making tiny adjustments to the motor mounting screws. Also, I see some extra holes drilled in the rubber drive block (see it at the centre of the motor mounting plate on the camera) Re these drive blocks. On a thread about flicker, Dirk DeJonghe jumped in with the comment that back in the day when ACLs were numerous and busy, a flicker problem was often traced to the rubber drive block, easy to replace. I quizzed him on what it was about, had it lost it's mechanical properties, were the holes worn, was there some untoward resonance between motor and camera, but he didn't know. Cheers, Gregg -

Zeiss 8mm, T2.1, Arri-B mount, with PL mount. For 16mm. These were designed for standard 16 and have a very small vignette on S16. Often used for digital with a lttle crop. Very sharp, it looked as good as the S16 format superspeeds, which resolve 200 lp/mm. It looked a good match to them. No marks, haze, fungus etc. Focus is smooth, with nice viscous damping. No bumps or defects. Iris is smooth and light. This generation of the 8mm has the same body design as a MK II superspeed but with slightly shorter barrel length. Integral focus gear and 80mm front. Focus throw is about 180deg. Focus marks in m and ft. The mount is fixed with eight screws. Comes with a stainless PL mount to replace the Arri-B mount. A lens technician will normally need to adjust collimation with shims after swapping mounts. Techs who collimate a lot with access to a lens projector are quite quick. Edit: PL mount comes without rear light baffle, but I think it has the standard thread to receive one. Some guys use them without baffles. You could 3D print one. PRICE..$1200; SHIPPING Was quoted 2-6 business days, but may be a bit longer. USA...$51.00 UK and Europe...$44.00 Other destinations just ask. No returns unless item is not as described. Any questions please ask. May have to space the pics over more posts.

-

Eclair ACL English 400'magazines (two).

Gregg MacPherson replied to Gregg MacPherson's topic in Cine Marketplace

The mint looking take up door that can go with mag2...It is missing it's light seal. It's the same diameter rubber as the throat light seal. Gregg.