-

Posts

3,320 -

Joined

-

Last visited

Everything posted by Aapo Lettinen

-

ALCS cp16r 45-speed crystal electronics

Aapo Lettinen replied to Aapo Lettinen's topic in Cinema Products

longer video with explanation https://www.youtube.com/watch?v=awlTwf3nyZA -

My A-Minima magazine project is moving forward now. Working on a newly made magazine which allows using standard aluminium 100ft daylight spools with the camera. Should have some kind of prototype in September and the final mags shipping before Christmas. I may post some 3d printed examples in August already when tuning the design. Price depends on how many ordered and when they are paid for. Preordered ones are considerably cheaper and preorders will help improving the finishing quality so highly recommended to contact me early on if interested in ordering these magazines. Approx target price for preordered ones is 2.5k or something like that. I will probably make one batch of preordered ones and maybe later on next year one extra batch which is more expensive, about 30% more expensive probably. Will try to keep the price under 3k in any case. They will be cnc machined in any case, made mostly out of aluminium and aiming for very good price-quality ratio. I should have possibility to make 400ft core load mags too if preordered very early on but they would be much more expensive than the 100ft. I would estimate from 4k to 5k price for the 400ft as it needs advanced electronics and more cnc parts and film testing. Dm here or on instagram (aaplet14). Facebook messages don't work

-

ALCS cp16r 45-speed crystal electronics

Aapo Lettinen replied to Aapo Lettinen's topic in Cinema Products

Testing the frequency response of the 6-pin IO module which is shared with the NPR and CP16R projects. doing couple of more tests and then starting to assemble the IO-modules for the final motors https://www.youtube.com/shorts/MSnojN3ciAY -

new ALCS compact crystal motor for Eclair NPR

Aapo Lettinen replied to Aapo Lettinen's topic in Eclair

Testing the frequency response of the 6-pin IO module which is shared with the NPR and CP16R projects. doing couple of more tests and then starting to assemble the IO-modules for the final motors https://www.youtube.com/shorts/MSnojN3ciAY -

ALCS cp16r 45-speed crystal electronics

Aapo Lettinen replied to Aapo Lettinen's topic in Cinema Products

Had to make a small change to the main board to enhance shutter sensor mechanical fitting and move a mounting hole a tiny bit. Waiting for new boards to arrive and working on the software in the meantime. Estimated shipping date is between 12th and 15th July for the preordered kits. I will make couple of extra ones half assembled and can finish them in late August/early September. If wanting to order those next batch ones one can get them for 850usd a piece including shipping if ordered now. Later on they cost from 900 to 950 with shipping. Looks like availability will be limited all the time so necessary to preorder if wanting a installation kit from future batches -

Anyone need a Crystal Sync motor for Kinor 16CX cameras?

Aapo Lettinen replied to Aapo Lettinen's topic in Russian Gear

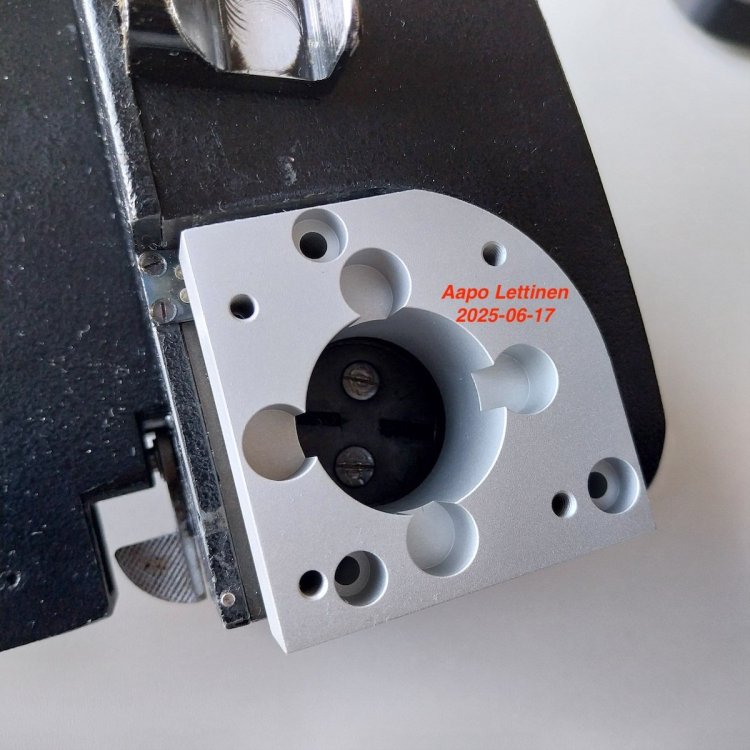

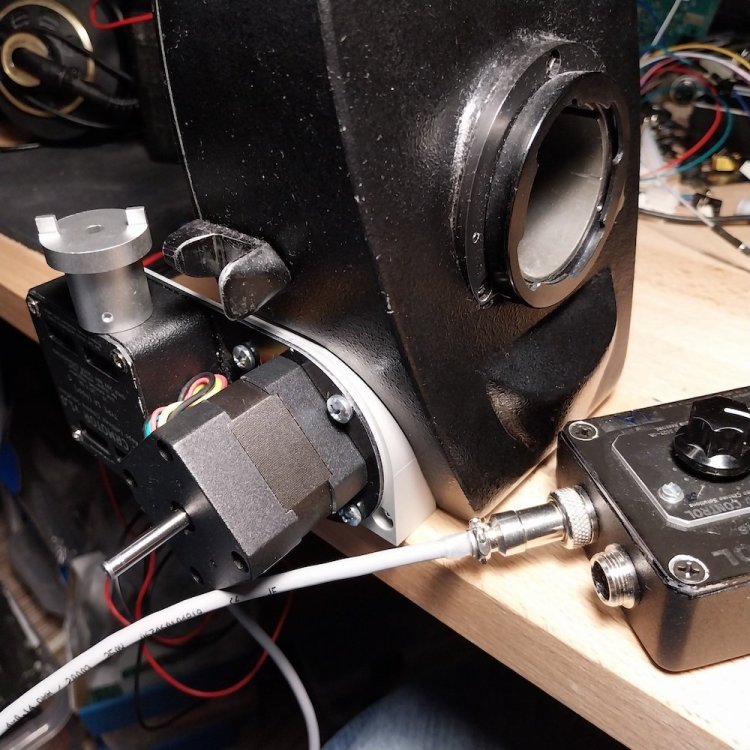

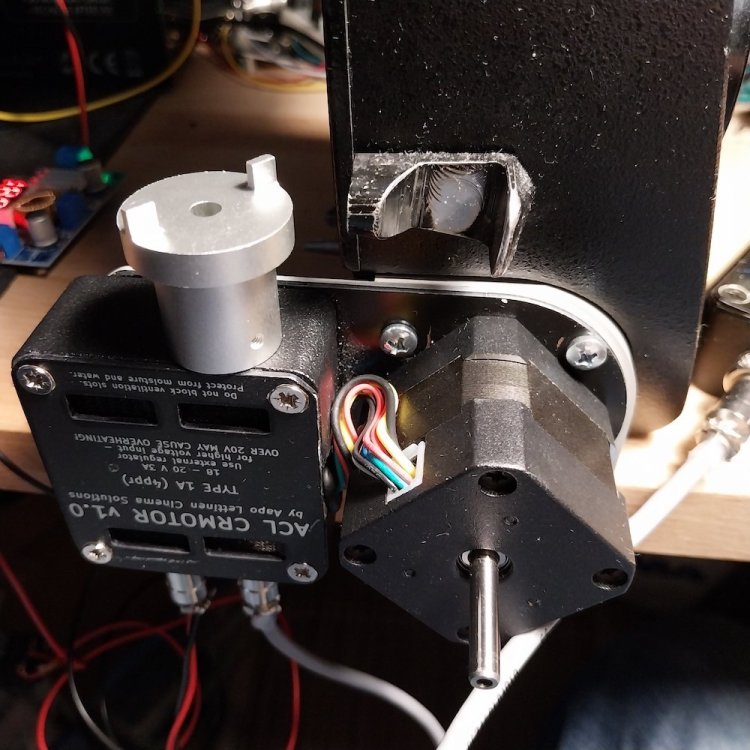

finished the mounting plate and axle adapter to mount my Universal motors to Kinor. tested here with my old 12-speed ACL motor as it has the same mounting system and was easiest available. Will use 10-speed and 4-speed Universal motors with the Kinor https://www.youtube.com/watch?v=66tdXrgfXXc&list=PLXvIUtmF3OxswaCvqLMXPKLQsvMZx9zpo -

Finished Kinor16 axle adapter and mounting plate, testing with my 12-speed Eclair ACL motor. I will make 10-speed and 4-speed Universal motors for my own camera, it was just quickest to check with my old 12-speed system because it has same mounting and was immediately available 🙂 So all the mechanical parts are finished now. Will wait for the 4-speed motor bodies to arrive and will then start assembling. Works fine with the Kinor https://www.youtube.com/watch?v=66tdXrgfXXc&list=PLXvIUtmF3OxswaCvqLMXPKLQsvMZx9zpo

-

CAD 3 view drawings (or 3D model) of Aaton LTR

Aapo Lettinen replied to Gregg MacPherson's topic in Aaton

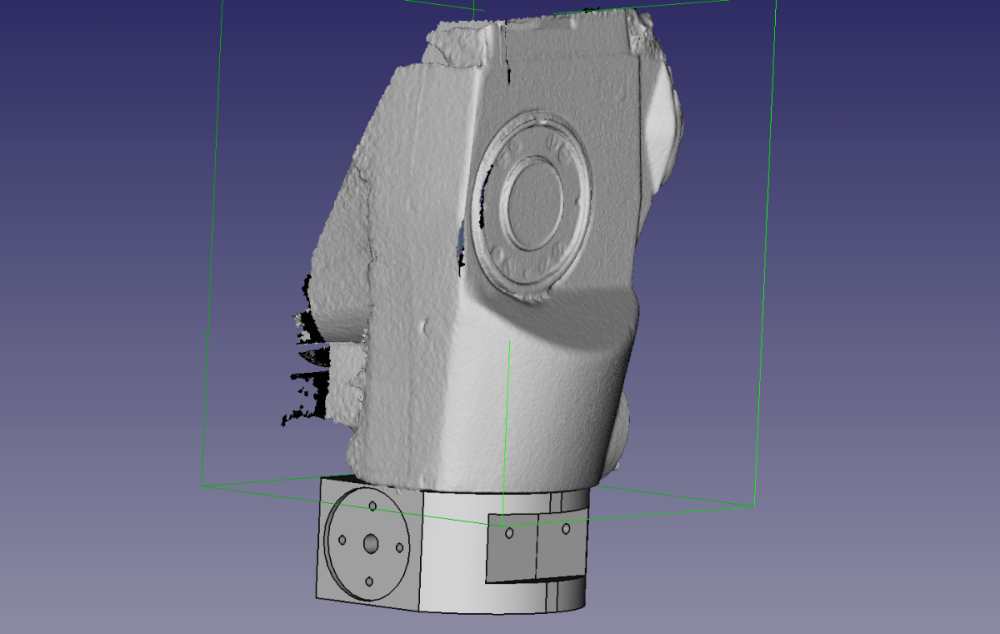

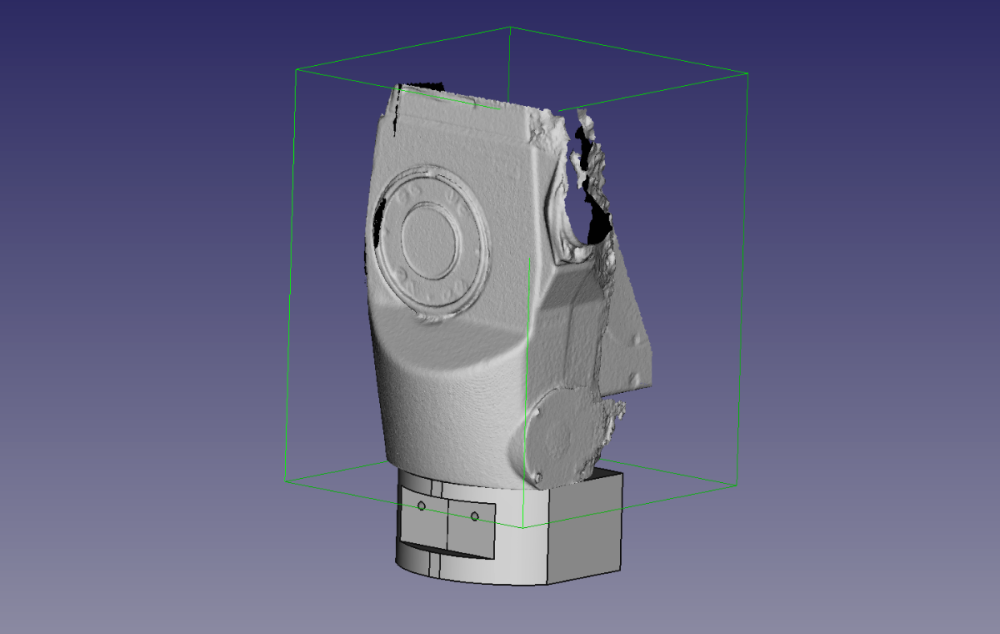

My scanner can do this type of basic stuff. Usable if you can verify the exact dimensions and fitting with the actual camera body constantly -

CAD 3 view drawings (or 3D model) of Aaton LTR

Aapo Lettinen replied to Gregg MacPherson's topic in Aaton

My current scanner is not very good so probably not worth to scan my ltr with it for this project but if you can use something like 1k or more on the 3d scanner you buy a pretty usable device. Most accessories can be made just fine by normal measuring without the need of 3d scanning. Rounded irregular shaped surfaces may need scanning but if you make cheeseplates etc you usually mostly need the mounting points info and some clearance details which can be measured just fine -

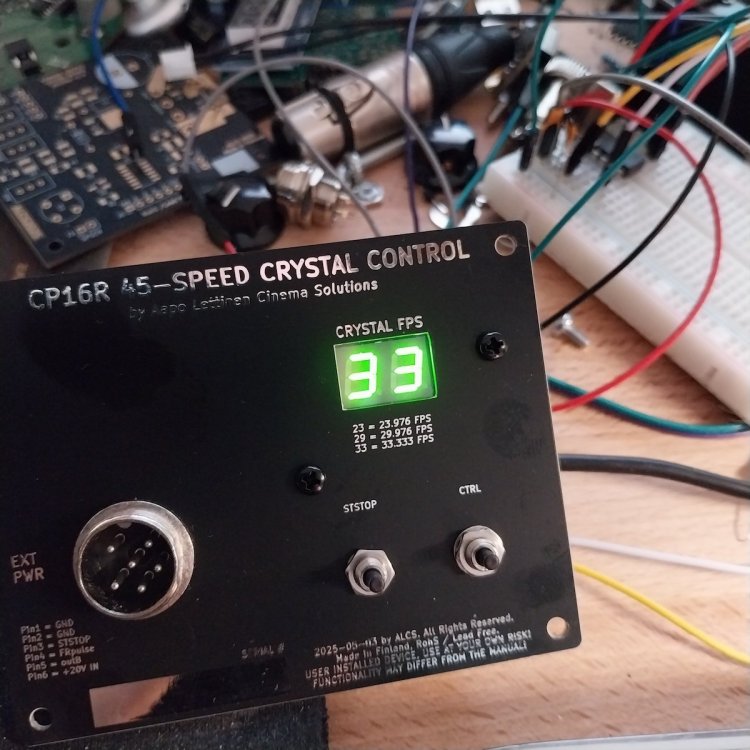

ALCS cp16r 45-speed crystal electronics

Aapo Lettinen replied to Aapo Lettinen's topic in Cinema Products

Prototype board for CP16R has slightly different connectors than the final ones will have to ease testing and the ICs are socketed whereas on final boards the ICs are directly soldered in place to make the board more reliable. functionality is the same so will finish the software with this easier-to-test board and then assemble the final ones when the software is final. -

ALCS cp16r 45-speed crystal electronics

Aapo Lettinen replied to Aapo Lettinen's topic in Cinema Products

Working on the CP16R software now. The 45-speed system will have PHASE CORRECTION function too, tested it today and works fine! so lots of value for the money I think Current feature list: 45 crystal speeds from 5fps to 50fps. will test if 3fps and 4fps work, if they do then they are included too very accurate tcxo crystal oscillator for extremely good sync accuracy even if shooting the full 400ft roll at once automatic shutter parking after shooting a take electronic inching with adjustable inching speed. makes it possible to check the gate by inching the mirror open after shutter parking possibility to feed external power to the camera and use the onboard battery at the same time (two power inputs on the circuit board only original electric motor drive needed, other stuff is replaced by newly made boards including the tachometer board, main circuit board, back panel and connectors as well as switches start-stop button and inching button when running, the inching button works as PHASE button bloop marker output to use with visual and audible bloop marker devices 1 pulse per frame output for external footage counters connector on the main board for sync warning led light back panel 6-pin connector (gx16 type) has start-stop, frame pulse out, bloop marker out and power in front panel 6-pin connector (hirose 10A type7 fm) has start-stop, inching, frame pulse out, blooper out and 4.6v 80mA power for external counters, switches etc. the 45-speed kit has the belt drive gear type (24fps black gear/25fps red gear) changeable from the display menu so it is compatible with both type of camera mechanics out of the box external footage counters available separately if needed, prices approx. 160usd to 350usd depending on features the 45-speed kit is user installable. Includes the circuit boards, new back panel and the small front panel with 6-pin Hirose, necessary switches, wire bundles and connectors. Possible to get without the wire bundles for cheaper (from 150usd to 200usd cheaper) . One gets good discount if purchasing more than one kit at once. the first batch of 6 is already sold out but one can order a installation kit from the next batch which will ship in August-September. If ordered before 1st July it is possible to get the kit from the second batch for 850usd including shipping. Later orders are 900usd including shipping. Only tcxo version available, there was no demand for the normal crystal version so will make all the circuit boards with tcxo dm on Instagram (aaplet14) or here . Facebook messages don't work -

Moonlight Color Temperature

Aapo Lettinen replied to Vivek Venkatraman's topic in Lighting for Film & Video

ungelled HMI is usually colder than 5600K, it should be something like 6000K but can be more depending on bulb condition and type etc. The ones I have used have often been a bit colder than 6000, I think they could have been closer to 7000K than 6000 -

ALCS cp16r 45-speed crystal electronics

Aapo Lettinen replied to Aapo Lettinen's topic in Cinema Products

Sent email now from underline***...gmail address -

I would get the LLC for insurance etc responsibility reasons if something happens during the production which could potentially create huge costs. You don't want to be personally responsible financially if someone is injured or a set burning down etc during production. Financial risk in case a project fails somehow other way is another reason like if the production stopped midway and cannot be finished, the debt goes to the company which is bankcrupted and you will walk away without your personal savings and 401k harmed

-

Anyone need a Crystal Sync motor for Kinor 16CX cameras?

Aapo Lettinen replied to Aapo Lettinen's topic in Russian Gear

Now when I have the mounting plate and axle adapter finished for mounting my Universal motors to Kinor cameras, I will assemble the two remaining 10-speed Universal motors soon for Kinor use. Will probably keep one for my own camera to be sold with the camera later, and another motor is for sale with Kinor mounting parts. Let me know by DM or on Instagram (aaplet14) if wanting to order a 10-speed motor for Kinor. Only one available as I have prepared to mainly sell 4-speed motors for Kinor use. Price 1000usd with shipping and all the necessary parts to mount it to Kinor 16cx cameras. -

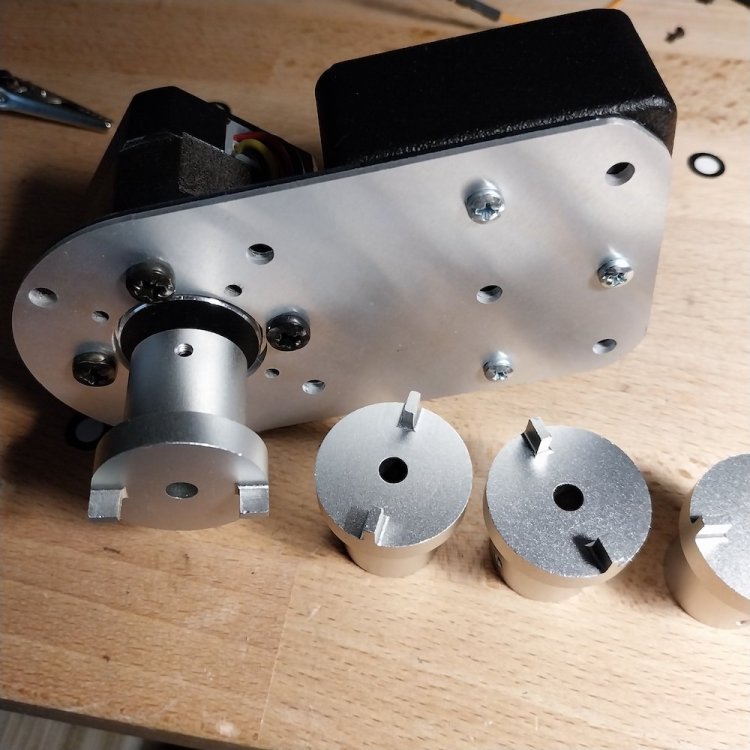

the 3d printing test was ok and I ordered three of these motor bodies in aluminium now. Should receive them in the end of next week. Because I have tons of other projects at the same time, I need to make smaller batches of these than originally intended. The June2025 batch of three motors is already sold but if you want a motor from the Late July / Early August 2025 batch let me know asap and I will order another batch of parts in mid July. Will need to know how many motors needed, if you need mounting parts or not and which mounting parts for which camera. usually I only stock one or two kits of mounting parts so will need to know 3 weeks beforehand if more mounting parts needed. DM here or on Instagram (aaplet14)

-

Final Kinor adapter to mount the 4-speed and 10-speed motors to the Kinor16 cameras! cnc machined aluminium. one can order the motor with this mounting adapter and axle adapter or get the bare motor and use the included cad files to make these adapters elsewhere. Or if you want to make some super special "add a huge cheeseplate to the adapter with v-lock mount and integrated light" then you can use the cad file and just add to it the stuff you need 🙂

-

I make custom crystal sync motors, control boards and software and can often troubleshoot and repair old motor electronics too if it is some simpler issue. Complex issues I often solve by designing and changing completely new control circuit boards which can have more and better features than the original electronics had. Located in Finland though so shipping is more costly. Advantage is that I can still make small production run custom stuff out of scratch (other techs sell existing old crystal sync designs so usually don't want to make new models with different boards and features or for different camera) . I can be subhired too if someone is for example just needing circuit board designed and assembled and handling the mechanical work by themself

-

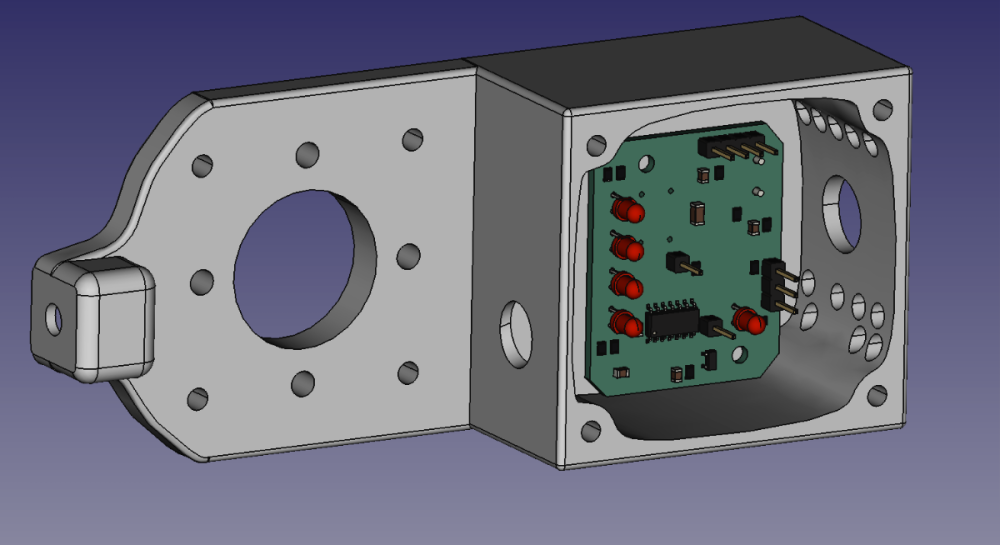

cad designing the 4-speed motor's aluminium body. will 3d print a test piece of out plastic to ensure dimensions and motor drive fitting, possibly this version can be sent to cnc machining already but we'll see 🙂 (circuit board cad model intentionally altered to not show all the details. I already have the final circuit boards and working on the software at the moment)

-

cad designing the 4-speed motor's aluminium body. will 3d print a test piece of out plastic to ensure dimensions and motor drive fitting, possibly this version can be sent to cnc machining already but we'll see 🙂 (circuit board cad model intentionally altered to not show all the details. I already have the final circuit boards and working on the software at the moment)

-

not knowing about the current reliability of Blackmagic cameras but would guess they are better now than in past days. In 2021 we had two Ursa Mini G2 's straight from factory and one of them did not turn on out of the box, completely bricked and had to be sent back for replacement. The replacement worked but was a bit unreliable at times. It improved however when there was some, ehm, theatre blood incident with the camera completely splashed and some of it got under the buttons etc. It was sticky after that but reliability bumped to full 100%, never had any issues with it anymore except the buttons being a bit sticky now 🤣 so back in the day they seemingly did not test the cameras in the factory, just put them in the box and let the customer do the quality control. I would guess they nowadays have someone to check that the cameras at least turn on before they are shipped as people would kind of expect that 😅 If the shoot is next year and you don't have tons of other stuff to shoot before that, I would maybe wait for half a year to see how other people like the 12K before purchasing. you will need it couple of months before shoot to ensure that it can be replaced if needed etc. but over half a year or close to a year is too much I think. when the budget and funding is secured then would be good time to proceed with the camera purchase. ------- For best possible lens options and super affordable shooting I would choose the L-mount version as you can use very wide range of lens adapters with it and there is autofocus lenses and cheap stills zooms etc available. I have shot low budget stuff for some years with Panasonic S5 and Atomos combo and have pretty good PL mount adapter for it and basic quality NikonF and EF adapters too. I normally use oct18 Lomos with the PL adapter and if necessary switch to Nikon AI-S lenses or L-mount zooms if needed. PL adapter would be very useful if you have proper lenses for it, saves lots of time when having sturdy mount with proper locking and good lens mechanics. just ensure the PL adapter is mounted very firmly with additional support so that it stays in place firmly and it will work great. If needing some lens option which cannot be sourced or afforded in PL you would just quickly remove the adapter and mount some L-mount lens or Nikon lens or EF lens to get the focal length or range etc you need. then switch back to PL when shooting basic focal length dialogue stuff or other stuff where pl lenses would be most useful

-

ALCS cp16r 45-speed crystal electronics

Aapo Lettinen replied to Aapo Lettinen's topic in Cinema Products

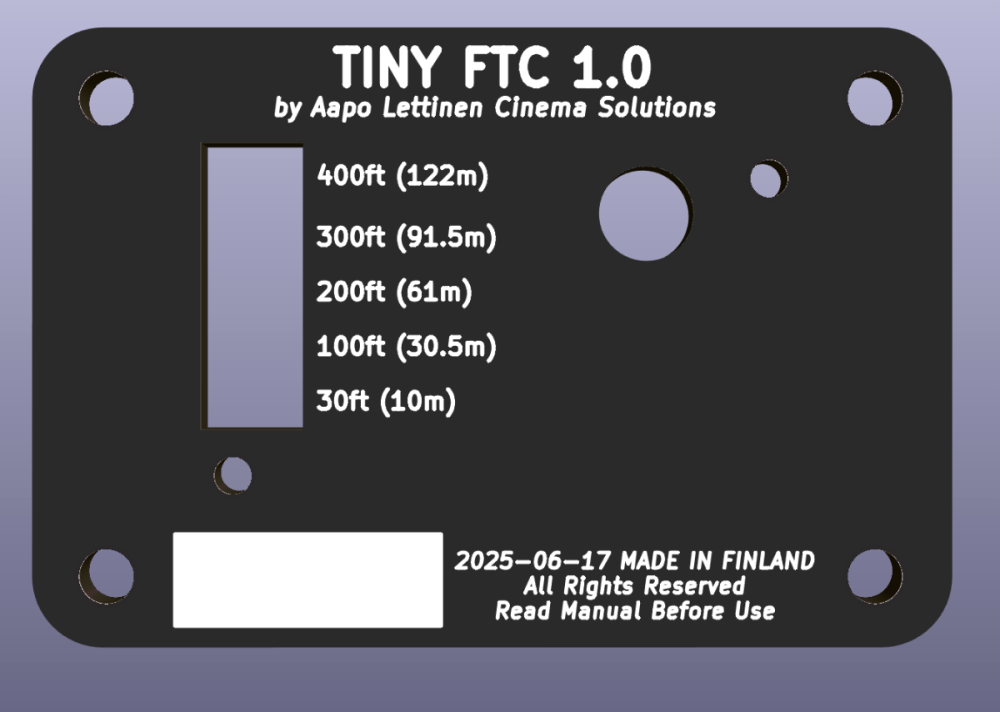

If needing a footage counter for the 45-speed system, you can check my Tiny Footage Counter v1.0 for very simple affordable counter, and it is possible to make other types of counters too like with 7-digit led displays or oled displays https://cinematography.com/index.php?/forums/topic/103526-acls-tiny-footage-counter-for-cp16r-and-other-cameras/ -

I am working on a small footage counter device, literally matchbox sized, which works with my 45-speed CP16R crystal update but is compatible with other cameras too. The same device would work with original CP16R electronics too if the operating power and correct signal is taken from the original circuit board which is why I made a separate thread for this device. Or could work with other cameras too if proper operating voltage and a 1 pulse per frame signal can be provided for the counter. It is, like mentioned, designed to be almost exactly matchbox sized and relatively affordable, something between 150usd and 180usd depending on how many orders I would get for the first batch which affects how much the cnc machined body of the device costs. The circuit board itself does not cost much, I am using almost all the money on the outer casing and connectors to get them finished nicely. The device is connected to the camera via a thin cable, the 45-speed system uses Hirose 6-pin connector to connect to the camera but original cp16r users can use whichever connector they like or permanently connect the wires inside the camera. if using the device with cable and connector, it would be possible to attach it to the magazine with velcro etc to keep it with the magazine rather than attached to the camera. Possible to reset to 100ft, 200ft, 300ft and 400ft and one led light to show each amount, additionally 30ft led to show when the mag is almost empty. Footage amount is stored in the internal memory and counts down until reaching about 3ft after which the small internal summer starts buzzing. Reset the summer with the button, then can reset the counter back to 100/200/300/400ft and shoot again. It is already possible to order these, I ordered the front panels now and have the circuit boards already with test samples assembled. Will work on the software and outer casing when having time from the NPR motor project, should be ready for shipping somewhere in August or September or so. dm here or on Instagram (aaplet14)