-

Posts

30 -

Joined

-

Last visited

Profile Information

-

Occupation

Grip

-

Location

La/SF

Contact Methods

-

Website URL

http://www.mikethebest.com

-

It might be too much for what you need but Fisher does make "ice wheels" for there fisher dolly's. I have used them when I was doing a show back east and we where on ice. As for how we pushed the dolly we found some boots for glacer climbing that had small rubber knobs on them that gave us a pretty good grip on the ice.

-

Overhead lighting - Practical location

michael best replied to Gregory Earls's topic in Grip & Rigging

if your in an office odds say there are ceiling titles so you can try these clamps http://www.filmtools.com/matscisclamw.html. aka scissor clips they can hold a par can with no problem. Then other option is to remove the ceiling titles and see whats above. lots of times there are cross beams or places to mount lights. -

SF Bay Area rental houses?

michael best replied to George Ebersole's topic in Accessories (Deprecated SubForum)

Chader camera or video fax are your best bets there are a few other smaller houses but those are the big ones. also try www.reeldirectory.com its a Sf based industry guide/listing -

I used to use excel However I found a program called PAID for both mac and PC it has some nice features that apply to the film/tv world. And it can be set to tell you when invoices are 30,45,and 60 days past due. I also keep and old fashioned paper calendar with job names and on it and a google calendar via my phone/computer

-

You have a lot of Legal options... If you worked in the state of California no matter what you signed as a film tech you are an employee. As such they are required by law to pay you at the time of your termination. (aka when you are laid off due to the job ending.) We normally give producers 2 weeks on a time card job and 30 days on an invoice. What lawyers have had me do in the past for non paying employers is at 30 days send a friendly notice saying something to the effect of just a friendly reminders that I have not been paid, if there has been a problem with my time card/invoice please let me know. If you dont hear back from them and no check comes at 45 days send them a firm 2nd notice via certified mail or ups fedex ect. And take a video of you putting the invoice/letter (if its a time card) and handing it to the mail clerk. At the same time contact you local labor office http://www.dir.ca.gov/dlse/DistrictOffices.htm and start a non payment claim. If you want and it is recommended hire a lawyer. And you will get paided pretty quick and they will go after out of state companies if you where hired in the state of CA. Most companies pay as soon as they are served by the Labor office and you most likely will get a small amount of intrest and you can ask for lawyer fees to be added if you hired one. However if the company challenges your claim you will end up in civil court but these judges tend to rule harshly on non-paying employers. This does take time and energy but its the best legal way to get paid. However do watch out of companies that claim bankrupsy as if they do they can avoid paying you all together. If that's the case you need to get a lawyer right away to get on the list of creditors. Also when invoicing never include labor and equipment in the same invoice as it makes it easier for an employer to claim you are not an employee but an "company" or independent contractor, which would fall under different laws. But once they give you a call time, and tell you when you can break for lunch and release you, you are an employee as stated under state labor laws. (this also means they have to pay SS, taxes, and provide workman's comp. regardless if you are invoice or payroll. The things we let slide in our line of work...)

-

Lighting Gell - Grip truck owners.

michael best replied to David Ross's topic in Lighting for Film & Video

If you can only have 3 rolls of diff. I would go Opal, 250, 216. I know with a 1 ton space is a huge issue, but having 1/8, 1/4, 1/2, and full + and - green is a good idea. If you can find away also have Hampshire and 251 to the list 129 is great but in a 1 ton you tend not to have many big lights so it won’t be used that often. Also you may want to invest in 1/4, 1/2, and full grid as well, but on the west coast most camera men use the white diff over grid. Heat shield is a good thing to own. Soft Silver Flex, Thin Silver/Thin Gold, and Rosco Scrim are huge money makers when used... John is right Gel/expendables in general are a huge money maker for grip trucks, Tapes, sprays, beadboard, foam core, and black wrap are where most trucks make there money as the basic grip package on the van might only make 200 a day and the lights need maintance and up keep. While I have seen owner operators sell the same piece of foam core 8 or 9 times to different productions. -

who makes this motion control rig

michael best replied to thomas-english's topic in Visual Effects Cinematography

That looks like the arm made by a company called autofuss. Its a San Francisco based company that was started by some former ILM people. -

Just had to deal with something similar to this today, it was an Image 80 but it weights about the same as a parabeam. The room was about 30x35 so wall spreaders where ruled out. We used the Max arm and it was perfect. If we had not had one of those on the truck we probably would have done goal posts with truss makers or a steel pipe, and asked the art department to help hide the stands if they edged frame. Hope this helps.

-

A tool belt is a very personal thing. I have yet to meet two people with there belts set up the same way. This is what I keep on mine for the most part. However I do add and remove things depending on the job and what the job needs. A Lindcraft “gaffer” pouch – I like this one because the flap folds down when you open it so you have easy access to your tools but you can close it should you be working around cars, or climbing scaffolding. I wear a Husky padded belt. From right to left with a too, pouch, tape loop with a ½ roll or less of photo black paper tape, and a very small roll of 1” white gaffers tape to label things. (a dog collar is what I use), a water bottle pouch (I found if I have a water bottle on me I drink it and if I don’t I don’t drink much water) A walkie holder, hammer loop, a leather pouch for a small steel workers c- wrench, and a tape measure holder. Inside the pouch. A 6” ultra wide mount C-wrench – This is big enough to fit a 7/8” cheese boro while light enough to not bother me after a long day. 4 in 1 screw driver - cheap one from ACE or Home Depot so when I lose it I won’t care. Probably the least used tool on my belt Allen set- useful for fixing lose risers and rigging. 3/16 allen speed wrench – you can buy the modern one for make one from a ¼ socket wrench and 3/16 allen on it. 3/16 works on 99% of all speed rail fittings, so it gets used a lot. Small LED flash light – a use a LED mini mag as its semi cheap, puts out a ton of light and holds up well. Matte Knife Small channel locks – like them small so they don’t weigh much but useful for grabbing stuff. Diagonal cutters – for grip chain, or anything else you might need to cut. 9/16” speed wrench – 9/16’s is the head size of a 3/8” bolt which is the size allen screw you use for speed rail. It comes in handy for rigging. Sharpie & pen, and something to write on for notes. Pocket knife – does not have to be super good but its fun to have a good benchmade or emerson . I wear gloves, as I like to wear them when handling wood and speedrail. Other things on the belt: A 10 oz hammer. – comes and goes depending on the job, but it’s super useful, 25’ fat max tape measure – fat max so you can extend it out to about 12’ before it flops down. A dog bone – this is a 7/8 speed wrench on one side and a ¾” speed wrench on the other, very useful for cheese boros and the ¾” work great if you are working with pipe and base rigs. Other items I have in a tool bag: Full size channel locks 8” c-wrench – the 6” ultra wide mouth does 98% of all jobs but you will meet some Keys who want you to have an 8” c-wrench so its good to carry one. Drift pin – useful when working with truss Scissors- always come in handy Metric allen set – I have found these useful more then I would have ever expected. A socket set – most keys will have in there work box but on commercial and smaller jobs they can be a life saver. A torpedo level Needle nose pliers A small file Chalk line – useful for cutting lumber or long gel cuts. And a few other odds and ends that I have found useful over the years. If you are new to the industry and still working as both a grip and Electric you might want to have a volt meter and volt sniffer in your bag so when you juice you are ready. A few guys I work with like to have there tools in lots of smaller pouches across there belt while other people, like one big pouch. It really comes down to personal preference. One good rule is to have it be conformable to wear and have the tools you need. But depending on what jobs you’re on you may have other tools that you may want, or find handy. A few other things you will want to have are: a really good set of rain gear and rain boots. (don’t skimp buy good quality stuff as there is nothing worse then tearing it because its cheap or sweating up a storm inside because your body can’t breath.) Super comfy shoes, and a set of comfy work boots. A hat for sunny days sun glasses and a good warm jacket for cold days or night work. Also if I wear pants to set I have a pair of shorts with me and if I wear shorts I have pants standing by. Hope this helps a bit.

-

Freyer Light 510-835-5800 Lighting by Steinheimer 415-672-4658 and DTC 510-595-0770 all 3 should be able to help you. Mike

-

I have to agree with Matthew, If you have not been trained you probably should not try and build one. when we put a 20x on a condor we are pushing the limits of what they are designed to handle. The CSATF class cover a lot of what we can and can't do with condors, and more importantly covers which condors we can and can't use. The best advice I can give you is to hire a Best Boy who has taken the proper training and ask him to build them for you or have a grip who has been trained come out and build them the days when you need them. I know this is probably not what you want to hear, but its better to be safe then risk killing or harming someone.

-

Lighting a bedroom night scene- thriller

michael best replied to Zakaree Sandberg's topic in Lighting for Film & Video

Without seeing a location I would say tent the windows from the outside and bounce your light in. But some places are ahrd to tent so you may want to talk to your key grip and see what he thinks. -

Its a motion control/ remote dolly, so the 2 grips the trained to set it up and handle all the software issues/needs. http://www.hotheads.tv/furio.html

-

Floor Stand Extend Long Arm China Ball

michael best replied to Ronald Gerald Smith's topic in Grip & Rigging

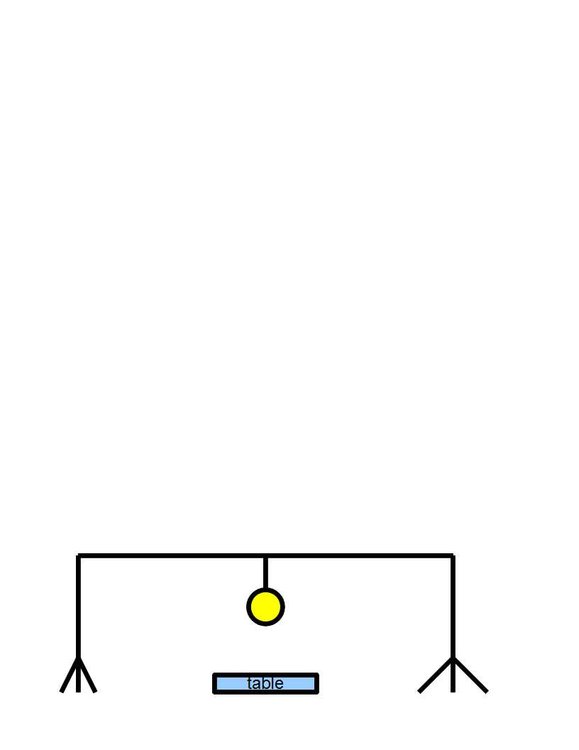

Tape is probably the fastest way to put the china ball up. But if you think the ball might need to move around a bit or that the 1 china ball might become a chine ball and oh wait can we add a pepper oh and a inkie you might want to make a goal post. all you need is 2 stands (3 riser combo, high roller, or mombo depending on how high you want to go and if you want it easy to move around.) a piece of 1 1/2" or 1 1/4" speed rail that will span the room, and 2 ears or big ben clamps to mount the speed rail to the stands. Then uses some #2 grip clips along the top so you can use the V top part to run your cable and you can tie off the china ball where ever you want it. And if say you need to add a small light or 2 you now have a mounting point for them, just add a pipe clamp. -

Motion control cranes - silence required or not ?

michael best replied to Chris Millar's topic in Grip & Rigging

A lot of the motion control cranes/dollies are used for effects shots or plate shots so sync sound is not super important. However some cranes/dollies are better for sync sound then other. However if you are doing any moves that require fast movments to sudden stops you will hear the gears and or the worm drive. I think its Pacific Motion Control that does motion control dollies and cranes that are fairly quiet.