-

Posts

7,836 -

Joined

-

Last visited

Everything posted by Tyler Purcell

-

Super 16mm film test - Light Leak

Tyler Purcell replied to Margaret Salmon's topic in Camera Operating & Gear

Slightly bad seal on the magazine is quite common, did you tape the edges? -

I work with young people all the time and many of them are in your shoes, they've always wanted to be filmmakers and they simply don't have the wherewithal to make that career jump for whatever reason. For many, they maybe got sidetracked with a career, for others it was growing a family or even military service, which prevented it. The one thing in common with all of them is that spark, that need to do something creative and share the results with people, kinda like a dopamine release. The current landscape with filmmaking in the Untied States basically completely over saturated on the creator side with simply not enough distribution potential for everything that's being made. For every 1 feature film that makes it through from indy to some sort of limited distribution deal, there are thousands of others which are sitting on peoples computers, maybe on YouTube/Vimeo or ever worse; Tubi. The increasing liberal arts degrees and democratization of filmmaking through lowering the barrier of admission, have both destroyed what was left of the already dying film industry. When you see the top filmmakers like Steven Spielberg unable to find funding for personal projects and Disney unable to make anything that isn't some sort of reboot, sequel or live action version of a classic animation, you know the industry is dead. So if feature filmmaking is kinda out of the cards for 99.95% of people, what is in the cards? Well, I know it may sound stupid, but going out and shooting stuff with your Bolex with your friends and starting a YouTube channel discussing your experiences, may actually pay dividends in the future. It only takes one person to watch your work and say "hey, I like this guy" and suddenly you're working on that persons project. Youtube is a great resource and if you put some money into your work, make things look good, it's a great calling card, especially in the film world, which is full of people looking for that next 16mm artist. Being a "creative" is easy, just go and create. Making a career out of it, is early impossible today. In terms of making a career out of this; it's a slippery slope and the amount of ultra talented and top industry people sitting on the couch these days, would make you sick to your stomach. Many will take ANYTHING to just make some money and it's just going to get worse as the Untied States becomes a more toxic country to do business with. I foresee many of the great resources we once had for grants and production loans, going away. It's see many people selling all their equipment and leaving the industry because the work is so fickle for most people, it's hard to base one's financial life off it. Today everyone is being ULTRA frugal in what they do and how they do it, making shit with minimal to no crew, which means nobody is making a career out of those lower-end shoots, the very same ones we use to make our bread and butter from. It's all about who you know, what they need, your skills and what you're willing to do to help people. You could work for free helping people for a decade and still never get the ability to make money from your learned/earned time on set. I've seen this with so many friends of mine, people who still think that big job that will win them a career in the industry comes rolling around the corner and they'll snatch it up. Those days are long behind us today and it's worse in non-media cities than Los Angeles. At least here, there is plenty of actual work, it's just hard to make a career out of what remains. With all that said, many of us have resorted to having actual normal full time jobs and creating on the side. I spent 6 years as a freelancer, it was a great time, tho stressful financially and I was overjoyed when I was offered a full time job and money was no longer a factor in my life right before covid. Has the full time job prevented me from going out and making stuff? Absolutely not, in fact if anything I'm more creative because I don't have to worry about money as much, so I can toss quite a bit of my money directly at making products, which is really great. I count myself extremely lucky to have caught the very tail end of this dying industry and been able to re-brand myself very quickly due to prior experiences and it all worked out nicely. Covid was the end for so much work and now that AI has basically taken over the marketing business, I fear those jobs are also long gone. So I launched an industry adjacent business in 2023 which has been a great way to continue being creative AND at the same time, offer resources to many "film" people as well. Maybe one day I can retire off this business, who knows, but having been in your shoes, having switched industries from something that pays well to something that doesn't, I wouldn't recommend that to anyone. Focus on the money, don't allow your need to be creative, suddenly propel you into debt or into some sort of desire to do more, make more, be something you aren't for the sake of switching careers. Nobody is stopping you from making stuff right now, so just do it and enjoy yourself. Whatever happens next in your filmmaking life, is irrelevant, just enjoy creating and showing people your creations.

-

Restoration of 16mm Technicolor & Fujicolor Cartoons?

Tyler Purcell replied to Alex Landherr's topic in General Discussion

I scan to DPX and export Pro Res from there. Pro Res 4444, has full color data AND is 12 bit. Pro Res 422, has half the blue and red color data and is 10 bit. So to retain the quality of the DPX files, we generally deliver Pro Res 4444. -

Restoration of 16mm Technicolor & Fujicolor Cartoons?

Tyler Purcell replied to Alex Landherr's topic in General Discussion

We do film restoration for a living here in Los Angeles California. We have a really nice automated process, which combined with a wet gate scan and very lightweight digital restoration, can give a pretty good result. We charge $.60 cents per foot for the picture and $.10 cents per foot for the sound for this process which includes full color restoration, picture cleanup (dirt scratches), sound sync and final Pro Res 4444 12 bit output files of any resolution you want. We normally do 4k workflows, but we can do 2k no problem. Turn around is quick, unless the film is damaged. Also if the scratches are deeper than our automated tools, we can use manual cleanup as well, but we charge per hour so that adds up a bit. In terms of making a new print, that's not a big deal. We have sources to achieve that no problem, including 16mm soundtrack. It's costly, around $350 per minute, but not difficult to do at all. Here is a sample of our automated service. It's not perfect, but it does a great job. -

I mean, I just processed and scanned someone's film that had severe X-ray damage. It was sharp 50D and the camera worked flawlessly, but the film was trash and 100% a throw away due to the x-ray damage. I was so sad for the guy, I think he tried to save a few bux and bought film from another country and just the shipping back and forward from that country to his and then to me, was enough to get it zapped. Probably got zapped before the film was shot to be honest, at least it looked that way. So yea, even if you nail the camera and lens, you still gotta be careful. Here in So Cal, I can drive to Kodak, drive to Fotokem, drive home to scan and the film is never leaving my side. But imagine you're shooting somewhere remote and you're shipping? I have never wanted to take that risk on my own projects, we travel with ALL our film, which is risky as well. It requires a technique of keeping the film cold wherever you go and making sure it doesn't get any direct sunlight sitting in the car. So quite a bit of our car storage is gobbled up by a huge cooler, which has these frozen packs all around the film, just to keep it in the 60F range. Then whenever we stop for the night, we have to take it all inside, stick it all in a refrigerator and re-freeze the packs for the next day. It's a lot of work and in the end, it's why when shit works, our results are outstanding. As a tech, I'd say the majority of running cameras that have issues, are from Bolex cameras. I don't even advertise Bolex repair, but holy crap, 60 - 70% of the Bolex footage I scan and obviously the cameras I fix for people, it's mostly Bolexes that struggle the most. I think it's also because they're low entry cost, so people who may not know much about cameras own them, so they generally don't know what to look for and maybe it's their first or second roll of film ever? Still, because I process and scan film for people, I see lots of shit man. I just scanned a roll yesterday that had a light leak along the entire upper edge of the film, the whole roll. Yet, the 2nd roll, zero problems. Like WTF? It just grazed the image and the filmmaker was like "what the heck is that", I had never seen that one before, especially on ONE roll out of what, 5 or so? I could go on all day about Bolex cameras and Bolex issues, suffice to say, I do think user error is to blame for MOST of them, at the same time, it's still the highest amount of errors I see from WORKING cameras. Obviously, I serve Arri and Aaton cameras the most, because people who own those cameras want them to be in perfect working order for their shoots, not the same with Bolex owners. They only come to me when they're broken! LOL 😛

-

People buy cameras, they do tests, maybe a little single roll film with one of their friends and then they disappear. Few months later, they call me and wonder if I can help sell their camera. This is the trend I see more often than not, especially with lower end cameras. Usually people buying Arri SR's or Aaton XTR Prod's, know what they want, but the K3, Beaulieu, CP16, Bolex, Eclair, crowd, really is fickle. They want that look, but they don't understand it comes at a cost. I see them all the time because I service those cameras AND scan their film. So I stay in contact with those people and they're cool. There was a point a few years ago, that I was shooting S8 or 16mm every single week! That all dried up in 2024 and this year, it's been entirely dead thus far. I planned a road trip in 2021 to re-create a trip I did with my parents in 1990. The concept was to re-create the super 8 film I did back then, so we could make a short film about my history with the railroads we went to visit. I wanted to shoot on Ektachrome because we shot the original trip on Kodachrome and I wanted to project the material when it came back. Ektachrome has a lot of cartridge problems, but we did some camera tests before we left and got acceptable results, so we went with it. We also brought a bunch of 50D Vision 3 carts with us as well, so if something DID jam, we could keep shooting. We prepped the carts perfectly, the camera ran through each roll normally without any jamming. Yet, when we got the film back, it was basically trash. Every frame of the Ektachrome material was jumpy and un-projectable. The 50D stuff was 100% flawless, perfect in every way for Super 8. We even shot 100D and 50D on the same day and the Ektachrome was always trash. Sometimes when the pulldown would grab the film, it would skip a perf and it got into this weird cadence where it would just not pull down like the pressure plate was not keeping the film on the gate. So many shots just didn't exist, which was a real shame. In the end, we scrapped the entire idea because it cost us $10k to do the trip and we didn't get anything back that was really usable enough from being on the road, which was the whole point. I wanna say we shot 10 rolls of Ektachrome and 8 rolls of 50D? That was the last time I even attempted to shoot Ektachrome on super 8 and I simply won't ever recommend it to anyone. I just did a portrait shoot in Colorado this winter on my friends Pentax 465. We tested the camera first, worked flawlessly. We did the entire shoot on film, no digital what so ever. The color negative rolls came out great, the E6 rolls came out great, we had 2 rolls of black and white, one of them appeared to be ok tho for sure not nearly as good as we expected and the other one, was blank. Sadly, that blank roll, was the big portrait shoot roll. So we lost 17 pictures out of 100 or so, which may not seem like a lot, but when your paying $5k to get 100 pictures, (trip costs and such), you'd think at least there wouldn't be some technical issue. So we learned a lesson; don't trust film cameras. Shoot digital and use film as a backup, which basically means don't shoot film because we can only carry 1 big camera on these trips, seeing as I'm carrying my 16mm camera. In 2023 we shot some Fuji Velvia and Illford 3200 on 35mm, our normal shop that processed and scanned for us, didn't do a good job on those scans. So we sent just those 7 rolls to another lab who we had used just recently to process and scan the color negative from the same shoot. We walk in, pickup the negatives, drop off the already processed Velvia and illford film, they scan it in a few days, send us the files on the web and we immediately run to a shoot out of town for two weeks. We come back and drive over to collect, they're closed (they have weird business hours). Ok fine, no problem, we'll check them next week. We go back, new sign on the door "out of town for a week", ok fine. Another month goes by, we call them and they can't find the negatives. We drive over and they've fucking destroyed the film. Yea, they threw out our negatives, as their procedure is to destroy after 30 days. I was like guys, you were closed! The mother fucker shrugs and walks away. No sorry, nothing. My boyfriend was going to punch him in the face because the Velvia shots were supposed to be turned into slides for a presentation project we were working on, they were one off pictures, not easily re-creatable. What a fucking nut bust man so now I can't even trust the good labs. I made a post about this that went viral on social media and dozens of people came forth saying they had similar issues with labs they've used. So there ya go, three more stories of three projects that basically didn't get finished because I choose to focus on the look, rather than focused on being creative and getting the shot. In the end, the decision is to either be creative and come back with something OR focus on the look with the risk you won't get anything. Doing art projects is cool, but the majority of people want a perfect finished result this day and age. They love that film texture, but maybe not at the cost of it being screwed up. Now, I have shot a lot of film in the last 4 years, so maybe my stories are a consequence of that, but in the end, what's happened to me is unacceptable and I have dozens more stories like this.

-

Yea, I don't think more cooks in the kitchen would have helped much. I always do camera tests after lenses come back from service and they looked fine to me. I've had plenty of jams and mechanical issues on non-Aaton cameras, but my Aaton cameras have been stellar. People underestimate the waste, it's the biggest problem with film. You can't manage film stock use based on raw numbers, it doesn't work. If you have a 3 minute scene and 2 minutes of film left, you're not going to shoot with that roll and change it. That adds up and by the end of the shoot, you got dozens of little rolls you have no use for. You may get some money back selling, but from my experience, most of them are too small, 100ft or so and nobody wants them. Maybe if that happens once or twice, ok but that happens four times a day on a 35mm show. You need to re-load mags with fresh film and move on, you can't just leave mags hanging and you aren't going to re-load a 100ft roll, makes no sense, so it goes into a can and that's the end of that. The extreme waste throws the numbers off and by the time you have real data, you've already blown through your budget. Now, this is why I try to go for 10:1 minimum on film, because at least you've got some of that overage covered. Also, less dialog scenes the better, with MOS stuff, it's way easier to use up those little SE's.

-

Yes most main stream productions have no reason to shoot digital outside of convenience and confirmation they got the shot. They have the budget, they have the crew, most are close to a lab, etc. They shoot digital because it's simply convenient and being able to re-play to make sure they have the shot and actually gives some guarantee they'll have it when they get to the editing room is something you absolutely do not get with film in this day in age. Here are a few anecdotal things that I've had happen and seen on other peoples films in the last few years. This train film series we're doing, what a mess man. Our first shoot came out good, but nearly every shoot after that we had major issues. It started with a bad lens that was sent back to me from the lens service shop not working properly. Hard to tell in the ground glass because there is no way to actually magnifying and see what's going on, even though our test shoot came out great. Got the entire 12 x 400ft roll shoot back, half of it was out of focus on the edges at any focus length, but it was horrible and useless wide open. Go back in October, this time with a nicely collimated lens, serviced body, this is going to be perfect right? Na, now Kodak has a problem with the remjet and it leaves a rain effect on all 9 rolls. I had to digitally fix every single shot we used in the final piece and it destroyed the look of the film, it looks wrong. Ok so we go back the following year, this time with some new toys, film is good, but damn man we had some strange issue with a new lens that I'm working with. This lens has an odd back focus issue, but because it's a zoom and because it has manual back focus, somehow in shipping to the shoot, it was out of focus. Can't tell on a film camera on the wide shots if it's actually in focus or not, so we just went with it, whole thing is soft. This winter, shoot 9, was one of only 3 shoots for this film series that came out perfect. Same equipment and same film. That's a horrible ratio, had I shot with my iPhone, it would have all come out, every single frame. Ok Ok, so documenting one off things may not be the best, how about narrative? In the last few years I've shot 4 narrative and 1 documentary project on 35mm with my own equipment. Two of the narratives I shot, two different labs destroyed part of the footage, both were top labs in the US. So both films were heavily altered to compensate because I could not afford a complete reshoot of those missing scenes. This meant, all the hard work and money we put in, went out the door. Had it been digital, zero problems, I'd be proud of those films and maybe even submit them to festivals. Instead, they were both nearly entirely wastes of money. Had I shot digital, not only would I have more coverage, but no issues with the finished product, it would just be perfect. Now, I also scan film for a living as well. So I get to see what other people shoot. Man oh man, it's RARE I get anything that's actually perfect. Yes, it happens, we did a feature few months ago that was MOSTLY perfect outside of a camera issue on one roll. We're doing a feature right now that's pretty good, but we're seeing some odd jitter issues every once in a while, mid roll and such, very weird. So for sure not perfect, I guess if that's what you're after, then ok? But if I were spending 2 million dollars on a feature film, I would want 100% perfection. I would also be pretty pissed if I had an entire roll that was screwed up. I don't think I could shoot and re-shoot every single scene on another roll of film, just to make sure I got it in the can. The risk is just too great, especially for narrative where you may not get another opportunity. I can always go back and shoot more documentary stuff, nobody knows what I got. But on a narrative, even if you schedule reshoots in advance, you may be boned. I have worked on many films that could only afford two days of re-shoots, but we needed 4 or 5 to fix all the technical problems, along with the story ones. Better to focus on story and at least if I shoot digitally, I know at the end of the shoot day, that I got it and won't need to worry about it. So yea, I love the look of film and I'm going to keep shooting it when I'm hired and on personal projects where I can cope/deal with issues. I have really enjoyed the last decade shooting film, but it's been a hit or miss situation for me, which is unacceptable this day and age. Also, I have spent years working on a YouTube channel about shooting on film, with basically no success because nobody seems to care anymore. There was a day not long ago, where people actually were curious, but now there are so many higher end YouTubers using film as a way to drive subscribers, it's hard to get in edge wise. I could make 2 videos a week about nothing subjects like they do and probably not grow without resorting to digital cinema. So I did ONE digital cinema video, my channel explodes overnight, over one video and people want me to do more on the subject. IDK man, having spent so much time shooting film and promoting film and getting absolutely nowhere outside of my business which is a guarantee anyway due to people NEEDING their film cameras fixed, I just don't see it as that much of a benefit anymore. Decade ago? Sure! Absolutely it was a door opener. Today tho, it feels old hat. Everyone shoots film today, I'm flooded with cameras in for service, people going out to shoot their first roll ever sorta deal. I love meeting them and helping them get their cameras running, it's a lot of fun. In the end, the only person who cares if it's shot on film or not, is the filmmaker. I don't think people won't watch your film because it's shot digitally, nor do I think they'll care about what it "could" have looked like if it was shot on film. I know getting that feather in your cap about shooting a feature on film is cool, so go for it! Just don't expect magic to fly out of the scanner. LOL 😛

-

The shutter is probably sticky and not fully returning to the position the switch needs it to be in. I have serviced many of these cameras, most have similar trigger problems. It's an easy fix, but if you haven't done it before, it's very tricky to get it back together again and keep it running. I'm happy to do the service if you want, I'm in Los Angeles.

-

Nope, it was Steve Yedlin's process of camera color science prep in camera and then post. They didn't have the money to do a film out. Where it's absolutely very complex and burdensome, I feel it worked well. Most people would never know and if there was a 35mm film out for theatrical projection, it would be even better. https://filmmakermagazine.com/124994-film-look-35mm-holdovers-emulation/

-

It's challenging, many features shot on 16mm, have moments where the image literally falls apart and it can be distracting in those moments. I feel with digital cinema projection, a lot of the film grain and such gets washed away, even with a 16mm screening. I have presented many films from DCP and have always been disappointed with the grain structure compared to my grading monitor. Where it's pleasant at the office, in the theater it's either non-existent/too soft to notice, or the image just falls apart. Where I do think 50D or 200T can work well if you're doing a western or something outdoors where you have more control over your light, if you're trying to make the el'natural look where you need higher ISO range, I feel it's a lost cause with 16mm. I almost prefer shooting everything on 35mm and use a more grainy stock like 250D or 500T for the entire movie, IF you want the grain in the film. I've been experimenting with realtime AI grain generation for digital footage and it's very impressive. Watch The Holdovers and you'll see what I'm talking about. We can manipulate digital footage so well today, the point of shooting film for theatrical, almost doesn't exist anymore. Even recording to 35mm and scanning that as your finished product, doesn't hold a candle to the digital manipulation from scratch. Things like halation and a bit of wobble/dirt along with the consistent grain, it all really adds up to create a great image. Where I love film and will continue shooting it myself until it no longer exists, but we're at a precipice where digital cinema cameras are very good, have excellent dynamic range and with the right lenses and post processes, can give a very pleasing image, which is tailored to the theatrical experience. If I were to shoot a feature right now, 16mm probably wouldn't even be on the table. I would probably do 3 perf 35mm or digital.

-

New Never Used Bolex SBM For Sale

Tyler Purcell replied to Dennis Toeppen's topic in Cine Marketplace

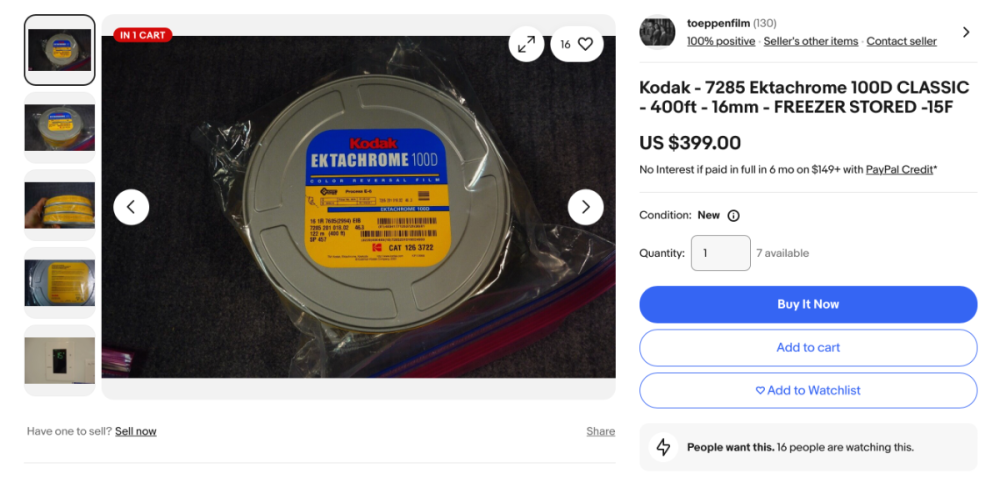

Market value is based on what people are willing to pay. First place to determine market value is by looking at what has sold prior. The "market" today are auction sites like Ebay, tho there are plenty of other ones that exist. Unfortunately, the rarity of the camera, does give one pause to understanding its full value. One such camera did sell (NIB) for $6k recently but it was not S16. Is the 1mm of added width, worth double the money? I say, only if it sells and I guarantee you whomever bought that $6k one, is absolutely shelving it. I do find it humorous how out of touch you are with pricing. This image below is one of your other auctions on eBay, a standard roll of 16mm Ektachrome 100D, basically the same E6 stock that's out today, but of course for twice the money because it was hermetically sealed in a bag and has an older looking sticker on the can. I love your comments in the discrpition as well "Forget about the new Ektachrome 100D, this is Classic Ektachrome 100D - with all the sugar and twice the caffeine. This was manufactured until 2013. It offers the look of classic reversal film - lots of contrast and great colors. It blows away the new sissy 100D." Even though it's basically the same stock. -

Yea, the ladder belts are kinda shitty, the older ones are made out of a polyurethane style material which the ozone corrodes over time. They fail from simply existing. Usually they last 20 years or so, but most people don't understand and they see the shutter spin, not realizing its not actually spinning properly because the belt has shattered and it's just barely moving along. The BL's are also a nightmare to work on, one of the most tricky cameras because of the way the movement isolation system was developed, so installing them can be very labor intensive. Arri moved away from these belts in the cameras after the BL, which means they are less prone to this issue. So you probably just have a belt failure. It's part of the reason I always suggest to people; its better in today's world to buy cameras like the Moviecam SL or Compact, because they use very much off the shelf belts which will be available forever and they are made of a rubber compound that doesn't degrade nearly as much. Also, BL's have many other issues, like the paper thin foam gaskets failing on the mags, especially around the mag throat. I've seen major corrosion on the film slides, which hold the film from the supply sprocket to the throat area, which need to be taken apart, re-aligned and put back together again on MOST mags before use. The 535 has a spiral slide, which is easier to work on, but those coaxial design cameras are a nightmare magazine wise. If you aren't a tech, you'll be spending most of your money fixing them rather than using the camera. Most of the time when I service BL's, they need a lot of parts. We have been making new gaskets/seals using a special 3D printed material which do fill the requirement, but aren't perfect. The aging rubber mounts for the mid plane to the chassis are liable to also be falling apart, which are tricky to get a hold of. As a tech, the screws sometimes get stuck and it's challenging to get the cameras apart sometimes because of corrosion. I'm always replacing screws in cameras that lived in humid climates, they're always a problem.

-

Nolan to use new IMAX cameras on next film

Tyler Purcell replied to Stephen Perera's topic in General Discussion

Yea, it's slightly more than vaporwear, which is unfortunate because it seemed like a great idea. He checked nearly all of the boxes, but clearly never got them quiet enough for actual sync sound production, which is a shame. I'm all for people making something new, but it needs to be better than what existed before and this evidently for some reason, just didn't fit the bill. I would make the gross assumption it was cost and good ol' Hollywood not needing MORE vistavision solutions, at a time when there were PLENTY of MOS VV cameras at rental houses. Seems like someone did wind up using it in Europe, but who knows if any actually sold. Thanks for the pictures, these are the only ones I've ever seen after researching this camera for years and coming to my own conclusions after nobody had ever seen one. -

I've shot a bit of 7222, never noticed it. I guess it depends on exposure. Also 7222 is a different backing, Kodak has already said they're using a silver backing on this new stock to prevent the added halation, so hopefully it works? It looks more like the Ektachrome backing and having shot a bunch of that, never seen it either. The Aaton 35mm cameras have chromed pressure plates, so that would be a problem. I need to first see the results and get feedback from people using chromed gates. If there are no real issues, then we'll just all move on. If there are issues and people have cash to deal with them, I can easily have new pressure plates for the Aaton cameras made, no big deal. I have all the specs, it would be a cinch to model them and get them made with DLC coating. I'm pretty sure there won't be any issues, because the stock is currently being used on a wide array of productions without modified cameras evidently.

-

Aaton 16mm cameras don't have chrome backplates, they are specifically designed to deal with black and white film which has no remjet. Arri cameras have chromed backplates, across the board. I know some people did make modified pressure plates which were black, but there aren't enough to go around. My main concern are the Arri 2Cs, Arri 35-3, 425, 235, Arricam, Moviecam, 416, SR, etc. We have some ideas on how to solve this problem, but without tests, I don't know if it's worth it. Currently Kodak has new stock available, but they won't give me a roll to test.

-

Well yea, you can't really upgrade line scanners that easily. Line scanners tho, kinda whole other world. The Cintel II is a single module and imager. It's really not the end of the world. The only thing different from doing an imager upgrade in a Lasergraphics is the added magic box. Well... they now have full AI auto tracking/AF. So I mean, that tech an easily be used to perf stabilize. Canon and Nikon use the same tech to de-warp lenses. This could be used to de-warp film. So I do think there is merit to the example I used, it's just not implemented by anyone. Scanner companies do not think like restoration technicians and they need to. The first person to release a scanner that you feed film and out the back end comes a fully restored file (within reason obviously) will win this battle. Where it's true scanner companies have attempted to sell concepts to help hide dirt/scratches, today with AI tools, there is no reason why a lot of the cleanup can't be done on the fly. Not saying it would necessarily be done in hardware, but you get my point. I was told multiple times by several people at BMD, over multiple years at going to dozens of events related to this industry, the entirety of the process is done ON SCANNER. They proved it by going into the real-time logs and showing that Resolve is literally doing nothing when scanning. I also asked them why their stabilizer tool doesn't work anything like the scanner tools, to which they said "because it's all done on scanner". Now, obviously playing back the file is different, it does use a tiny bit of resources when doing so because well, the CRI files are compressed. I know the CRI's are not stabilizing in playback. I was told that camera is identical to the original 4k Blackmagic camera. Not sure how true that is, but they did not develop the imager at all. Yes, they should have updated the blackbox by now. Imagine how many 2k scanners were thrown in the trash for the same reason? Yea, I mean it's a big problem, no argument. They make it work by doing realtime HDR scanning, which hides the issues with the noise floor. I'm not gonna sit here and say their imager is good, because it's not even in HDR mode, but I have been pretty happy with the results over the years, if you don't actually care about getting 4k out of it and understand its limitations. Partial debayer is when you deal with de-noise, profiling and edge reconstruction in imager, this saves considerably on data AND most importantly, means your computer does not need to do these tasks, which lightens the load. Yes, it's very proprietary.

-

They've been working on it for years. Remjet is a big problem because it means MP and still film are basically an entirely different product. Without Remjet, you can process both ECN-2 and C41 without much consequence. This would mean one string to make all films. It would also mean still only emulsions, could be used in MP cameras (proper perforating) which means more cross pollination between 35mm stocks. I see this as someone in their MP team wanting to keep their product alive and negotiating with corporate. I know the guys in CA have done a shit ton of work to keep MP prices down and keep it even existing. Corporate wants to raise MP prices to still prices per foot, which would basically end MP as we know it today. Possibly the way they determined to fix this, is to simply change the emulsion to lower cost, a great way would be to keep the emulsions all the same. The new anti-halation layer supposedly doesn't work well, in initial testing people are complaining about lots of halation especially on the lower speed stocks, where there is so much light bouncing of the pressure plate. One of my friends is doing a test this week, let's see what he says. It would be easy to fix cameras, the pressure plates would need to be DLC coated. It would not be difficult OR very expensive. The thickness is the only real problem as we would not want to upset that. DLC can be made black AND non-reflective if necessary. It's also very slippery so it would work great as an anti-friction device as well. 16mm cameras may not be as effected, as many already have black pressure plates. Where I'm worried this MAY actually rase prices AND cause people to back away from film, I see it as a means to an end for Kodak, at a time where the cost of goods is going to skyrocket. I have seen the writing on the wall for a few years now, so I've been divesting in film personally and buying Digital equipment so I can keep making films when Kodak finally raises prices to a point I can no longer participate.