Robert Hart

Basic Member-

Posts

381 -

Joined

-

Last visited

Everything posted by Robert Hart

-

DETACHED BLUE SENSOR JVC GY-HD100 AND OTHERS OF THE ProHD FAMILY

Robert Hart replied to Robert Hart's topic in JVC HD

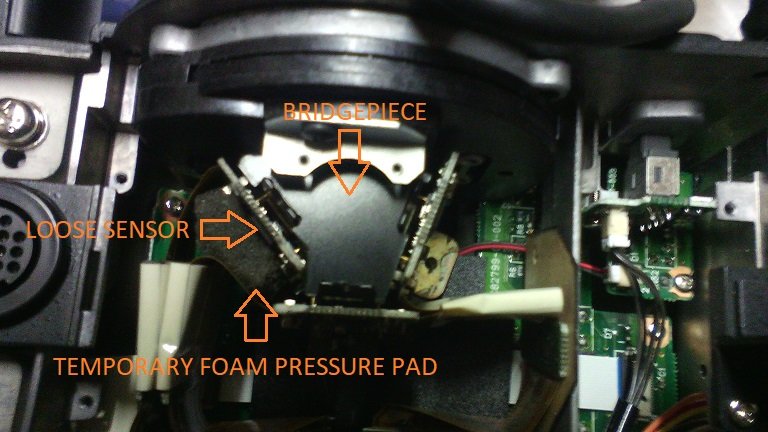

A small update.Here is an illustration of a temporary support for the detached sensor which enabled me to establish just where in space it should be. The next step is to build a different support attaching to two pairs of screws and is microadjustable and yet enables enough clearance that the small dobs of adhesive can be spotted upon the four corners of the sensor to prism junction.The material needs to be viscous so that it does not creep or wick in between the sensor and the prism through capillary action.The adhesive appears to be a non-brittle material similar to white water cleanup bathroom sealer.The bridgepiece is cut from formica or laminex which is a material similar to thermosetting resin or bakelite. It is insulative to avoid any chance of electromagnetic fields being introduced into the original steel jig pieces which function also as heatsinks. EMF seems to have been an issue because magnetic strips have been taped to the ribbon cables.The bridgepieces block airflow so cannot be a permanent solution.The far bridgepiece has been made to be a precise fit to another intact sensor block with three screws. There are elbows in the far jig pieces which have threaded holes which are conveniently are a match to the camera body screws. This cannot be an accurate exemplar because each sensor itself is very slightly different and must be aligned before the adhesive is applied in factory. It does however get very close. The bridgepieces are cut to be a very slight interference fit to the jig pieces. -

DETACHED BLUE SENSOR JVC GY-HD100 AND OTHERS OF THE ProHD FAMILY

Robert Hart replied to Robert Hart's topic in JVC HD

For those who have the endurance to remain curious, any bridge pieces which are made have to be vented to allow the small fan to push air through. As Tyler has mentioned above, the little processors on the PCBs the sensor chips are mounted to can get hot enough almost immediately to be on the pain threshold. The bridge pieces are best made of formica or laminex sheet which is a thin thermosetting resin similar to bakelite. I have established with these it is possible to get a good alignment but perfection will only come from screw adjustments, not finger pressure and barely tightened screws. Once I have established a position for the loose sensor I will make up different mounts attached to four conveniently located screws on the rear face of the mount to confirm to the restored position of the sens and use that instead of bridging all the sensors together. -

If they really have a passion and commitment to this project and are not doing the entitled thing, they will find a way to make the financing happen or find a patron. That patron should not be you unless it pleases you to sponsor the project for the feelgood or "the exposure". When it comes to loyalty down the track from up and comers, you can pretty much assume it will be non-existent if they step on the fast train. Those who hire a new director are not likely to want any attachments which come with him or her.

-

DETACHED BLUE SENSOR JVC GY-HD100 AND OTHERS OF THE ProHD FAMILY

Robert Hart replied to Robert Hart's topic in JVC HD

It seems that it can be done. This phone pic of the LCD screen is of the image from a JVC GY-HD111E with detached blue sensor relocated using rough cardboard bridges made from cereal packet cut with razor blades. Obviously the adjustments would have to be finer before the image on a large display screen would hold up but this is a good start. What a pity I did not do this a few years ago. I might have made a few dollars. Now I am just patching up museum pieces and there is no worth in it. -

DETACHED BLUE SENSOR JVC GY-HD100 AND OTHERS OF THE ProHD FAMILY

Robert Hart replied to Robert Hart's topic in JVC HD

Tyler. There is a little fan in there but the blue sensor is highest in the group and probably receives more heat due to convection. There is another dynamic in play with the blue sensor in that the ribbon cable is only just long enough and imparts a lot of constant draw tension on the blue sensor board. Over time I suspect this has been the mechanism for the sensor coming off. This can be converted into a pressure load by adding a spacer between the upper surface of the blue channel ribbon cable and the underside of the SD card slot assembly above. Whilst doing a "live test" with the blue sensor bridged on one side to the other sensors and manually adjusting the free edge, I observed that the green sensor, whilst apparently firmly attached can flex very slightly on the adhesive and spring back. I did not try the red sensor. Sleeping dogs are best left to lie undisturbed. When playing around inside a camera with a loose blue sensor with the right casework removed, take care to insulate between the edge of the blue sensor and the green sensor below it. They will short to each other and the camera will go dark. I thought I had destroyed it but it seems that this crashed whatever computer is inside it. When switched off and switched back on again it was fine so I dodged the bullet that time. Phil. The blue sensor coming off, creating a yellowish hue which won't whitebalance out has been a common failure mode with the JVC GY-HD*** camera family. Another failure I have with one of the three cameras I have here which has an intact sensor block is that half of the green channel has faulted leaving a purplish hue on one side. The fault is in the sensor and its downstream connector. The fault carries over to another camera when the block is installed in it. That sensor block is my template for making the bridge pieces. Each sensor block will be individually slightly different because of manufacturing differences between sensors when the imaging chip is first installed. I am hopeful that the differences are so miniscule that simple tapered screw adjustments will enable the pixel rows to line up. The system was accurate enough to enable fine flying head adjustments on the old Sony EIAJ reel to reel video recorders. Shimming was another matter. The adhesive seems to be similar to the water washable white bathroom sealer and is not dead hard but slightly pliant. It cleaned off from both the sensor face and the prism glass like bathroom sealer with a small wooden blade, a cut-down icecream stick. I don't like my chances but I have sent a request to JVC in the US asking what they used for adhesive. It appears that there are only four small points on the corners where there is adhesive in spots of about 1mm at most. -

This has been a common failure in this camera family usually manifest firstly with blue rimming on hard contrast edges, becoming a soft and separate ghost blue image or no blue image at all, just a blue moon shape and a yellow cast in the rest of the image which users cannot white-balance. The fix from JVC is to replace the entire sensor block at considerable expense which given the obsolescence of these cameras is not justified. Because of the manufacturing technique and the attachment of the sensors to the prism by adhesive alone with no other mechanical support, alignment of the detached sensor and reglueing it is not an option. However a means of attaching the blue sensor using two bridgepieces from the green and red sensors attached to jig hardware which remains on the individual sensors may be an option. From rough tests it sees doable, the issue being finding space to add small adjustment screws.

-

Age becomes an issue when there are many kid eagers out there prepared to provide their brand new camera and work for monkey-tucker. Good luck to them with their energy and their ambition. In the meantime once a succession of them have worn themselves and their cameras out subsidising an exploitative industry and a production entity eventually gets burned by a reshoot, us wrinklies will have gone on the dole queue.

-

Properly Exposing on 16mm Film Question

Robert Hart replied to Max Thomas Schmitz's topic in General Discussion

The 1/3rd stop light loss may or may not be applicable. It will depend if you are using an original lens set supplied with the camera which has been calibrated to the camera for the numbers on the iris ring to appear "as if" there is no light loss. Lenses from other sources will be that 1/3rd stop underexposed. Better and smarter folk than I may explain this more accurately and and fewer words. -

intermittent overexpose of frames on 16mm footage

Robert Hart replied to Habib Beh's topic in General Discussion

There will be inside the gizzards of the camera, a centrifugal governor of some sort. For sake of smallness, the governor in a Bolex H16 clockwork camera appears to be controlled by friction of small leather boots inside a polished brass bell. The frame rate adjustment sets what rotational speed the friction pads engage the inside of the brass bell. Other industrial or internal combustion engine governors use spring resistance against the centrifugal force and some sort of mechanical linkage to a power controller, usually a throttle lever. What is inside the Bell and Howell I do not know but it will be a centrifugal governor of some kind. If there is any contamination of the friction surfaces in a Bolex, it must be cleaned. Otherwise there will be slight flicking as the governor hunts for correct speed across a wider variation than it should. If there are varying amounts of friction in the whole drive train, this will force the governor to hunt heavily for correct speed. It likely will not overspeed and underexpose, but at tight spots in the drivetrain, speed will drop back and cause your over-exposed frames before the governor can step back to restore speed. It is likely a service is needed which includes cleaning old dried lube off gears and thrust faces, relube and cleaning the governor, which should restore your camera. In the Bolex, a well maintained governor, set against a strobe source whilst the film transport is loaded will hold the camera in sync with a modern sound recorder for about 15 seconds, sometimes more. The Bell and Howell speed control may not be as accurate but there certainly should not be any light frames in each run except at starts and stops. You also need to be decisive when you button on and off. If you relax the trigger slightly, it may drag on the transport and cause your light frames. You also should not allow the spring to entirely run down before you button off. The high speed part of the mechanism may continue to run on under its own inertia and pull the spring end out of its retention. As mentioned above, given the price of the camera, you need to decide the cost benefit of having it fixed. Any other cameras out there which are offered for sale, unless they have been recently serviced, will likely have some speed issues, so my personal preference would be to suck it up and have it serviced. Mechanical devices with plain bearings, gears and springs, do need regular maintenance whether they are being used daily or sleeping on a shelf for six months.Your camera may well have been in hibernation for years. I was not able to hear sound with your video recording. A sound track with the vision might be more helpful. Please heed better advice from other folk. -

Help please on Lens Adapter

Robert Hart replied to charles pappas's topic in Lenses & Lens Accessories

Is it Cameflex to Aaton? -

Shooting old monitor (getting rid of moire/ aliasing)

Robert Hart replied to Bradley Roberts's topic in General Discussion

If you want to go with live display, you could try to defocus the LCD screen by cutting a piece of lighting tracing-paper diffuser to screen size and oiling it with barbecue spray or spraying hair spray on the textured face of the tracing paper to make it more transparent. You may of course still get screen-refresh artifacts. There may be other ways of doing this which are healthier for the LCD display you are putting it on, - oily side not touching the screen of course. You will likely need to use a spray. Wiping or brushing will leave bands and streaks. My personal preference would be to put a paper chromakey green mask on the display and adding the screen vision in post. With older curved CRT displays, it becomes a bit trickier to get a good lay up of a paper mask. I have had adequate but not best results using spray-on contact adhesive on a CRT screen then laying up a piece of carefully precut green pooltable felt cloth which has been lightly pre-sprayed with the same contact adhesive. You need to let the adhesive dry to be as tack-free as possible because you need to interpose a large piece of paper between the cloth and the CRT screen and carefully ease it out as you firm the cloth down to the CRT screen's curved glass surface. You most likely will still have to trim the edges. With care you should be able to "walk" any wrinkles out and not have to lift the cloth. Lifting the cloth will stretch it uncontrollably and you may have to start over. Please take the advice of others with more valid comments to make than mine -

You could probably get away with a non-toothed belt or suitably sized neoprene seal ring in place of the toothed belt but the footage counter would no longer register accurately and have varying and significant errors. Depending on how tightly the take-up clutch is adjusted or how much slippage the external o-ring magazine drive belt yields, there would be slippage on the internal belt which very likely would vary as the magazine drive loaded up with more film on the take-up core. A bricked or broken camera is highly likely to have a belt with missing teeth.

- 7 replies

-

- cinema products

- cp16r

-

(and 1 more)

Tagged with:

-

Inside the CP16s there is a memory battery. When this deteriorates, it may ooze onto a crystal module directly attached to the motor control board. It is quite a mission to get at it. You might strike lucky if the crystal module is covered with dried ooze and is successfully cleaned off but more likely it will have been damaged. Ken Hale at Whitehouse Audiovisual may have the necessary replacement PCB but I have not been in touch now for several years. There was a new digital replacement motor control system and rear control panel developed and sold. I don't know if the designer/builder/vendor is still trading or has any remaining inventory to sell. More details can be found at this page :- http://www.cinematography.com/index.php?showtopic=43586

-

How to degrade an image in-camera to simulate Old Spyglass

Robert Hart replied to Joe Taylor's topic in General Discussion

The magnifying glass suggestion is probably as good as any to try. You will be of course to use ND filters and shutter speed to control the light because as a camera lens, its aperture is wide-open. Once you have established the point forward of your camera's lens mount where sharp focus occurs from the magnifying glass to your camera's sensor, you may be able to control light with a simple round aperture hole tidily cut in a thin piece of card positioned between the magnifying glass and the camera. you will need a lightproof enclosure around the magnifying glass and the path between it and the camera. -

How to degrade an image in-camera to simulate Old Spyglass

Robert Hart replied to Joe Taylor's topic in General Discussion

Here is a young man's reflective arrangement of a plate camera and DLSR. -

How to degrade an image in-camera to simulate Old Spyglass

Robert Hart replied to Joe Taylor's topic in General Discussion

This linked clip of rather poor HDV quality was shot using a Sony HVR-Z1E, a 4+ power close-up lens for relay and a home-made AGUS35 adaptor with the groundglass removed for aerial image and a Sigma-for-Nikon 50mm - 500mm zoom attached on the front. The aerial image typically has a lower contrast and more often than not picks up the edges of the iris in this arrangement. It was with the available tech of those times, the only affordable long reach option for me at the time. Here is a link to a home-build AGUS35 groundglass device being dismantled to give you a sense of the principle. In this instance it is an image-erecting or "image-flip" arrangement with a prism pair. For your purposes that would not be a complication you need to have to deal with. Here is a large format arrangement which uses a plate camera, a Nikon DSLR, a macro lens which eliminates the need for a dioptre and a groundglass. This arrangement is unlikely to work in aerial image mode due to the wide angles of view of the optics and the projected image but who knows? In this instance, the builder has used a fresnel "condenser" lens in the path between the front lens and the groundglass to eliminate the vignette defect you may will be looking for. The "Coatwolf" camera used for the independent film "Bellflower" was a similar arrangement except the used was one of the early SI2K camera heads. -

How to degrade an image in-camera to simulate Old Spyglass

Robert Hart replied to Joe Taylor's topic in General Discussion

You could try using an old zoom lens, decollimate it drastically relative to the mount by removing or adding shims which are often found between the mounting tail of the lens and lens body. Finding focus will be interactive with the zoom movement and you may find the edge of the image goes off focus or weirds out in some way. Make sure you do not lose any shims so that you can restore the lens later. As mentioned above, optics in the olden times were not perfect. Until a very recent theft, I had an old pair of binoculars dating from about 1910 of a non-prismatic design which yielded a clean image to the eye. Old optics are often degraded due to age and no longer representative of their original image quality. You might otherwise try a leaf out of the old 35mm groundglass adaptor book and shoot the aerial image from another lens in front of your camera's own lens. To achieve chroma abberation, edge softness and even coma ikn the edge as a bonus, you would use the cheapest single element screw-on close-up lens you can find and stack the for 7+. You could get away with 4+ but your forward offset which I mention further along this response would need then to be about 7 or more inches ( approx 800mm ). The method is awkward and unwieldy. You would attach a 7+ close-up dioptre lens to the front of a camera lens of about 100mm focal length for a small sensored DLSR, the smaller the front element of that camera's own lens, the better. Then position the tail of another lens about 6" or 150mm in front of it and aquire the aerial image of that lens in front which will need to have a large exit pupil, think 20mm wider or more. You will need to make a lightproof enclosure or your image will be contaminated by ambient light. To set up, your aerial image plane, you will use a small paper target with some marks on it. Move this forward of your camera with its lens and close-up dioptre until you have a clear image. The position the flange face of your other lens in front a further 44mm forward if it is Canon, 46.5mm further forward if it is Nikon or 52.0mm furthur forward if it is PL-Mount. When you remove your paper target you will be in the ballpark of aquiring an aerial image through the lens in front. That image will appear upside-down. Depending upon the size of the exit pupil of that lens you will get a vignette which may or may not be manageable. Ff you have the front lens focused for close-up and moved slightly rearwards to restore sharp focus on a distant object, then there will be a definite edge defect in the image and likely a vignette from the iris as well if you close it. Whilst I have some regrets at dismantling old equipment, an old groundglass relay adaptor like a Letus35 Extreme or Ultra can be used in aerial image mode with the groundglass removed. You need however to use the camera type for which it was built which usually means 1/3" sensored cameras and a focal length setting on that camera's own lens of about 60-70mm. The relay lens and mounting ring on the back of the Letus is also specific to camera type. With an erecting groundglass adaptor like Quyen and Hien Le's Letus, Dennis Wood's Brevis and Wayne Kinney's later SG Blade designs, the groundlgass panel is relatively simple to remove after the adaptor's front case is opened up. A P+S Technik Pro35 is suited to 2/3" sensored cameras but removing the groundglass is a real mission and likely to be destructive. There have been a few experiments with large format plate cameras by either filming the screen image of a large 6" groundglass plate or bouncing the large format lens image with a mirror forward onto a reflective screen within a lightproof box and photographing that reflected image. You would find this very bulky and awkward. My personal preference might be to use post effects as suggested in previous responses above. -

Angenieux 16-44mm zoom ( Variable prime ) T1.1.

Robert Hart replied to Robert Hart's topic in Lenses & Lens Accessories

Dom. Thank you for your response. I have some machining skills and small lathe and have previously made PL and IMS mounts and adaptors for Speedboosters. PL-Mounts are tricky but doable if you are precise and get the method right. The mount arrangement in this lens appears to be as you say, an intermediate piece with the mounts in my two specimens permanently fixed to it by press or thermal shrinkage. I may go the route of a third-party ARRI B/Standard to PL-Mount adaptor and turn out the inner diameter to suit or remachine the Cameflex or Aaton tail with a suitable thick shim to move the flange face forward. The entire intermediate piece is a bigger ask of a home machinist in that the thread pitches are very fine. One version of a PL-Mount I have seen on reduser appears to have been an intermediate adaptor and PL-Mount tails for Optar Illumina lenses. If I can get hold of the machining detail for that intermediate adaptor I would have a shot at making it. Collimation I can handle - with due care of course. -

As a long shot I enquire if anyone has a machinist's diagram or design for a PL-Mount for one of these fairly rare lenses. I am building up one out of two which have different defects. One has a cameflex mount, the other which is very incomplete but fortunately has a good front element has an Aaton mount. Given the move to 4K+ these days,a 2/3" / Super16mm digital cinema camera image is a harder sell but then again am not quite so hard to please and happy to use an SI2K with Optar prime lenses. Any advice appreciated. An online enquiry with Angenieux yielded no reply.

-

Somebody like Les Bosher in the UK would be able to do it and do it better than I by a huge degree of quality. You would have to buy a Metabones Speedbooster with 0.71x "Ultra" optical cell in it and remove this from the Speedbooster. Nothing destructive has to be done to the optical cell itself so you would be able to re-assemble and resell it if you want. The optical cell is identical across all the "Ultra" 0.71x speedboosters. Used off eBay may be the most affordable way to get one. Metabones or Caldwell Optics will not sell you the optical cells singly. I can provide the construction method and some dimensions. Les Bosher would probably prefer to measure the work to be done himself. https://www.ebay.com/sch/i.html?_from=R40&_trksid=m570.l1313&_nkw=Metabones+Speedbooster+ultra&_sacat=625

-

If the lens is silver you may find it was made by Tamron. Years ago, I used a version of the Sony/Tamron lens from an old 1/2" reel to reel EIAJ camera and recorder system on a Bolex H16, then later on a Bolex H16RX5 for stringer news work. It was adequate but not outstanding for sharpness. This vision was shot with the lens. Unfortunately the transfer from film to digital vision is very poor but it may give you a hint if you compare the sharpness of the image with the blemishs and scratches on the film itself.

-

Here is an image of the Nikon F-Mount arrangement with the speedbooster installed. The front face of the mount is rearwards within the body of the turret. You will observe extra unused screwholes in the bronze mount adaptor. I have not yet devised a lock pin arrangement which will fit within the available workspace of the PL-Mount camera body

-

Here are some images of the PL-Mount with Speedbooster installed. You will observe that the rear of the clamp ring now approaches extremely closely to the front of the turret body when the lens is secured.

-

I could not get the link to work as a windowed view in the responsive post second above this post, so here it is again, windowed this time.

-

Further to the above, an enterprising fellow in Italy has devised a focal reducer to fit within the camera throat of the URSA Mini 4K and URSA Mini 4.6K cameras. It is called the Lucadapter. Unlike my arrangement, it apparently does not require the 4.2mm setback of the lens mount flange faces of the Nikon F-Mount and PL-Mount that my arrangement of the Metabones 0.71x optical cell requires for infinity focus to be preserved. Because the URSA Mini Pro camera throat is occupied by the ND filter system, it is not suited for fitment of a focal reducer like the Lucadapter or custom adaptor for the Metabones 0.71x optical cell.