-

Posts

2,364 -

Joined

-

Last visited

Everything posted by Robert Houllahan

-

Most of the film color timers learned by trial and error, Brad who was at Cinelab was an incredible color timer and did not like the hazeltine as he found it to be slow and cumbersome he timed on the bench with color cards and experience and made incredible timed prints. Unfortunately he passed away a few years ago so much of the knowledge he had was lost except for the tools which are still at the lab. For Di workflows on film you might reach out to Steve Shaw at Light Illusion as he has an extensive toolset for calibrating a Kodak digital LAD with a densitometer through the negative and print stages at a lab and building a matching 3D viewing LUT so the look of the print can be closely matched in the DI theater. For more controlled general printing you can use a Kodak LAD and measure the patches with the densitometer for ECN2 consistency and then print that LAD onto print stock and then measure the LAD patches on the print to get to a base printer light setup on the printer and process at the lab. From there color timing is primary print lights +RGB = darker in all colors -RGB = Lighter in all colors +G = more magenta -G =less magenta etc.

-

Anyone try the Lasergraphics Archivist scanner?

Robert Houllahan replied to Daniel D. Teoli Jr.'s topic in Post Production

I think it has a metal plate system that "holds down" the film and makes it run flatter through the gate. This probably really depends allot on the tolerance for being flattened by the presumably very shrunken film being scanned. -

ALCS Single-Speed Crystal Controller for CP16R

Robert Houllahan replied to Aapo Lettinen's topic in Cinema Products

-

ALCS Single-Speed Crystal Controller for CP16R

Robert Houllahan replied to Aapo Lettinen's topic in Cinema Products

Not yet let me take a look at the camera this weekend -

super 16 lenses to match angenieux optimo zoom

Robert Houllahan replied to Connor Keep's topic in General Discussion

Canon 11.5-138mm zoom. Canon Super16 10.6-180mm T2.7 zoom. -

Kodak did about 1.3B in sales last year and turned a bit of a profit, I think most of the sales volume was in advanced materials and inks etc. The MP products division and the still film division are both profitable I believe.

-

Arri Scan XT vs Lasergraphic scanstation 6.5K

Robert Houllahan replied to Abel van Dijk's topic in Post Production

I would go for the Arriscan if you value color accuracy and DPX is really not that hard to deal with on a modern machine, just transcode it to ProRes4444XQ if the scan house won't offer that. The Arriscan is a true RGB and true 16bit machine when run in 2-flash it is in another class of machine compared to the still excellent Scan Station. The Arriscan is definitely superior in terms of color reproduction. -

Need Help with Old Optical/Contact Printers

Robert Houllahan replied to Nicholas Lymberis's topic in Film Stocks & Processing

Can you post some pics? Do you want to make prints with the Model C printers? Do they have tape readers? -

This also works to re-plasticize older films I have a seal-able lab chamber I put films into with camphor tablets and it works really well for films which are starting to turn.

-

East Coast (US) Lab Recommendations

Robert Houllahan replied to John Jaquish's topic in Film Stocks & Processing

I would definitely recommend us, but I am biased. www.cinelab.com We have two LaserGraphics Scan Staton scanners and an Arriscan and we run 16mm in ECN-2 / E6 Ektachrome / B&W Reversal and Negative all in their own individual linear processors. If you want to email we can put a complete film and processing / scanning quote together. -

New Countdown Leader

Robert Houllahan replied to Robert Houllahan's topic in Film Stocks & Processing

Thanks the 16mm film recorder has really come along nicely if I can say so myself ? I have more refinement to do on the software side but pretty decent now in Version 3 Working on a 35mm version now in addition to the aging Arrilaser(s) and the Imagica recorders I have. -

New Countdown Leader

Robert Houllahan replied to Robert Houllahan's topic in Film Stocks & Processing

I built the 16mm recorder V3 around a Mitchell 16mm pin registered camera for best possible steadiness. I am building a 35mm version which I hope to possibly use a 8K D-ILA (LcOS) imager for but will probably start with a Eizo medical imaging panel first. -

HI I put this academy standard countdown leader together and recorded it to 16mm. I have both 2.5K and 5K scans of it freely available. 5K Scan: https://drive.google.com/file/d/1nOw8Jga41eSlQvwgD7fA2-7xsXVH0QAJ/view?usp=share_link 2.5K Scan: https://drive.google.com/file/d/1nU3RRve3KJe5nu6SBeAhPQiSlnVKVMhP/view?usp=share_link

-

ALCS Single-Speed Crystal Controller for CP16R

Robert Houllahan replied to Aapo Lettinen's topic in Cinema Products

OK sounds good let me check the camera and let you know. -

ALCS Single-Speed Crystal Controller for CP16R

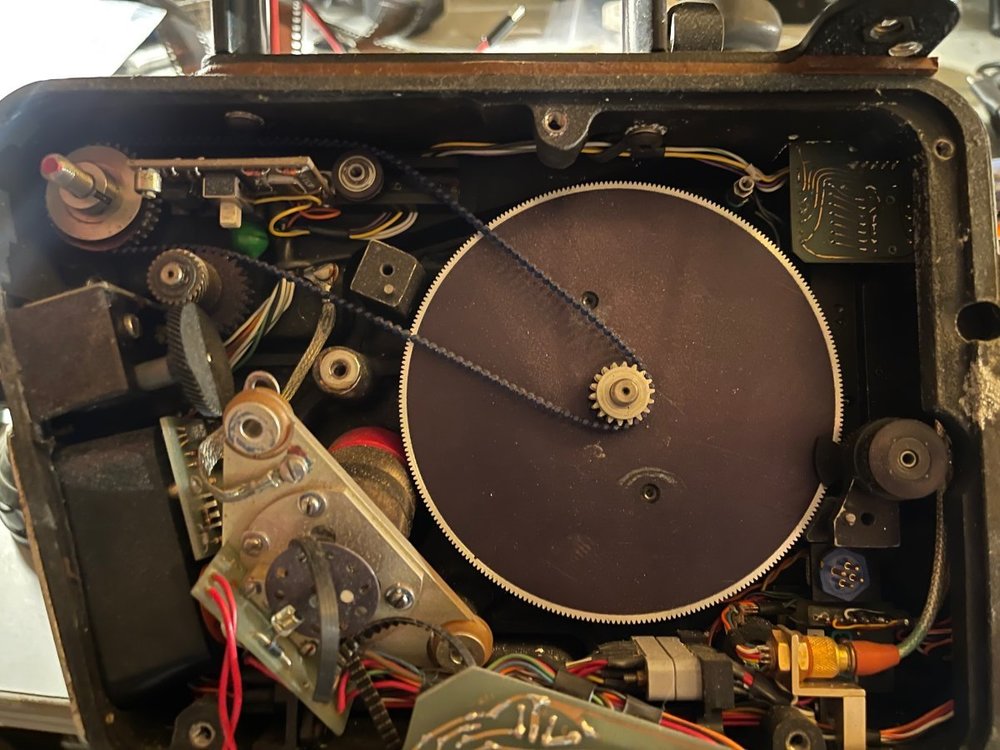

Robert Houllahan replied to Aapo Lettinen's topic in Cinema Products

I have a CP-16 at Cinelab would like to update it so consider that a order. -

We have done plenty of digital to 16mm with an anamorphic squeeze, most for recording and re-scan. It would not be a problem to make a squeezed 1.33 print with sound and de-squeeze it in projection with a anamorphic projection lens, there are plenty of them on eBay. Just be aware of the very narrow sound on 16mm which is mono and frequency and DR limited.

- 5 replies

-

- film recording

- 16mm

-

(and 3 more)

Tagged with:

-

ORWO NC500 initial thoughts

Robert Houllahan replied to Tyler Purcell's topic in Film Stocks & Processing

I just received the 1600ft of NC500 16mm from Orwo. -

Shooting Ektachrome 100D with Nizo 561 macro

Robert Houllahan replied to Hugo Bueno's topic in Super-8

I have shot some S8mm 100D carts in basic auto exposure camera with good results and in general we recommend rating it at 80iso or as others have said 64iso for overall best results. This is developed in Fuji Pro6 7-step chemistry not the easier tetnal blix process which is less controlled. -

Film spool unwound when unloading 16mm magazine

Robert Houllahan replied to Will Jacobs's topic in Film Stocks & Processing

We have received all manor of unraveled film in many forms of container for processing. If you do not feel confident in re-spooling the film you can leave it in a "ball" in the bag and put it in a box and send it to your lab and the lab techs will take care of it, we have allot more experience handling film in the dark than you do ? Also it can be removed from the container in the dark room to be spooled back on to a core, expect some delay for this order. -

ORWO NC500 initial thoughts

Robert Houllahan replied to Tyler Purcell's topic in Film Stocks & Processing

I got a notice today that Orwo is shipping some NC500 I ordered. -

ORWO NC500 initial thoughts

Robert Houllahan replied to Tyler Purcell's topic in Film Stocks & Processing

I highly doubt it would run as E6 but we can try it. I saw the first of the NC500 at Cinelab today and I rather liked the grainy pastel look of it. Of course because it is client film I cannot share any clips but I found it pleasing. I was scanning it on one Scan Station and the other Scan Station had a Pro Spot Kodak 500t job shot on a 416 with the best glass it was super sharp and rich. As it was a spot with a big sports figure they really knew hoe to expose and shoot. It was a huge contrast to the NC500 which was also S16mm but in kind of low light and a bit underexposed. The NC500 was not anywhere near as steady as the 500t on the 416. I don't know what camera they shot on but probably a SR2 as it was student work. I really liked the way the Orwo rendered flesh tones and colors. I got a few rolls coming and I will split that amongst Cinelab staff and do some shareable tests. -

Examples of Pull Processing 7219

Robert Houllahan replied to Freddie Whitman's topic in Film Stocks & Processing

I would second the 200t recco it is a really nice stock. We can push or pull up to two stops for ECN easily and more with some machine setup. -

4K Spirit on eBay - $5k opening bid

Robert Houllahan replied to Daniel D. Teoli Jr.'s topic in Post Production

The gate probably cost as much to make as a Scan Station.