Charlie Peich

Basic Member-

Posts

278 -

Joined

-

Last visited

Everything posted by Charlie Peich

-

Have you tried using the ground wire that came with the camera? One end is plugged into the power cord (the negative side), and the other end was plugged into the torque motor. Sometimes the grounding on the torque motor to the camera body didn't make very good physical contact. Not all cameras had this problem. See the 2 pics... This little wire had a habit of wandering away never to be seen again 🤷♂️

-

Hello Jack....... I've attached an ad from an Alan Gordon 1983 catalog showing your camera. Unfortunately it doesn't mention your 24 volt power supply with the 2 cables. Your best bet would be to open the camera and see how the wires are attached before sinking any more money into this camera. You will have to enlarge the ad in order to read it. 🙁 (my guess would be those plug into 2 12 volt batteries... just a guess!!) Your next concern would be getting hold of the magazines loaded with film. Or, you could load them your self after countless hours trying to load them in the dark. 1st, you would have to spool down the film into 50ft loads of DOUBLE PERF film on a small core (found in the mag), then load the magazine. The magazines are old, and are prone to jamming in the camera. Even Kodak loaded magazines back in the day would occasionally jam 🤷♂️. There are articles about loading them on the net. There may be one place that sells preloaded mags...... 'Film Photography Project'. https://filmphotographyproject.com/16mm-magazine-film-now/ After WW-II, there were a couple of guys modifying the GSAP camera and had mounted a finder on the unit. I have a multi page article on modifying the GSAP camera (lots of pics) that was written after the war. To big a file to post here, so if you want it, send me an email address through the forum. Good luck! Charlie

-

Bell and Howell Filmosound 302 Upkeep and Maintenance

Charlie Peich replied to Scott Barton's topic in Bell + Howell

302 and 8302 operating instructions Link to pdf file: https://acrobat.adobe.com/id/urn:aaid:sc:va6c2:cc8d78ab-0353-46d0-a6e8-19b5ebc5be90 -

Bell and Howell Filmosound 302 Upkeep and Maintenance

Charlie Peich replied to Scott Barton's topic in Bell + Howell

Greetings Scott! Looking at this thread, I see nobody has answered your original question: "But there has been some information that I have seen that there is a drive-gear within the units that are plastic and when they break it is essentially a terminal condition. But also that their use was not consistent throughout the product line over the years but was introduced at some point. So my question to the group is if anyone knows if my units might contain these potentially problematic parts or if they might (hopefully) precede them? Any information on preserving these projectors would be appreciated. Thanks." A quick answer is..... NO, there are no plastic drive-gears in your 302, 8302 projectors. There are no plastic parts in the drive train nor the intermittent movement. (proof below) While the cracked nylon worm gear was a hot topic way back, those gears were in the successor to the FilmoSound 100-302 projectors, the FilmoSound 500 series. Apparently, the grease used on the gears in the new machines did not mix well with the nylon worm gear, and over time the gear cracked: In worse case scenarios, they fell apart, and the projector stopped working. Ouch. (a shocking photo to scare you)....... Then service people started making replacement worm gears out of better material. It solved the problem. Yes, changing them out was a real challenge. Back to the 8302 projectors....... Lubrication....... Does your 8302 projectors have the 3 oil cups on the top of the gear box? The earlier ones did. Then B&H came up with the phrase "permanently lubricated" projectors just before they changed over to the 500 series, which were..... permanently lubricated. No more getting oil on your fingers I guess. B&H also did that with their silent 16mm projectors and their popular reg 8mm projector the 122. Jeeeez, how hard is it to put a couple of drops of oil in your expensive projector?🤷♂️ This info is from a 1970 service manual for the 8302. I have a service manual dated 1958. No mention of 'permanently lubricated' projectors in the earlier manual. No oil cups on gear box.... Basically, B&H stopped building their original all metal mechanical projectors and created the new models. This changed occurred in the late '60s and early '70s. Go to Paul Investor's web site and you will find manuals for the 8302 projectors. There is a manual that is the parts manual, and you can see in the exploded views how your machine is made. https://www.paulivester.com/films/projector/manuals.htm One last item, there was another feature on the 8302-L models that may have been standard for that version. I have not seen this on any other projectors. It's the disc at the top of the aperture plate. It is a disc you adjust cropping the top and bottom of the projected frame. B&H 302 & 8302 service manual, Page 9 - 10 part # 24 'Aperture Plate Assembly, Variable'. Does your machine have that? So, which model 8302 do you have? I have an 8302-L model with a tube amp that doesn't have oil cups. Does that mean my permanently lubricated projector is still good after 55 some years? Charlie P.S. Do you have an operating instruction manual for your 8302? I have one, but it's for the earlier 8302 models. Need it? -

WTB: B&H Filmo 70DR/HR Viewfinder

Charlie Peich replied to Okto Simaia's topic in Marketplace Listings Under $200 / €200

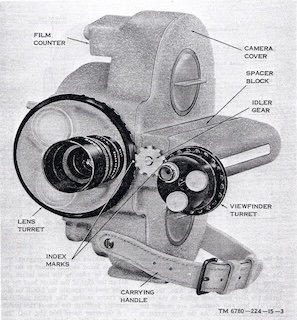

Okto, Have you found a finder or the parts to cobble one together for your 70HR? Parts are scarce now. What motor did you get with your camera? Does the motor work? The previous owner probably removed the HR finder and spacer block to accommodate a Zoom lens with a reflex 'dog leg' finder. Fairly common back then. Too bad the original HR finder wasn't sent along with your camera. Be careful adapting a DR door and finder. There are slight differences between the DR door and DR finder and the HR door and HR finder. It all depends on how much you want to spend and how you are going to use the camera. Charlie -

I found this pic of the cover with 'Oel' on it in an auction on eBay....... https://www.ebay.com/itm/166553521094?hash=item26c75d0bc6:g:DH0AAOSwABxlptJe The seller does not include the model 'A' designation for the camera in his description. Looking at this camera in the auction, it appears this camera was used in a blimp. Arri introduced their 1st blimp with the introduction of the Model IIA camera. A brief history of Arri's 35mm camera... This was written by Kling Photo, Arri's 1st importer of Arri equipment in the USA. I'm thinking that the 1st IIA's had the cover with 'Oel' printed (the model II did not have a cover over the movement). Then at some point they changed it to the English spelling 'Oil'. But, why did they change it?? You are right about the cover for the IIB. I have a Model IIA that was built in the 2nd half of 1957, it has 'Oil' on the cover....... My camera built in Germany was sold by Arri to its 1st owner in Sweden. Why would they leave an English word on the cover? I bought my camera from a private individual, so it did not go through the USA importer when I acquired it. You are right about switching the labeling on the the cover for the 11B model. A way to quickly identify the IIB??? Also, there weren't that many changes to the IIB camera. Charlie

-

Fabian........ The plot thickens....... ???

-

-

Is this what you have?

-

70HR/KRM info, instruction manual, tips

Charlie Peich replied to Philip Forrest's topic in Bell + Howell

Mike, I should have added the following info about the spring belt for the 400ft mag in my previous post. The Spring take-up Belt for 400ft mag: Bell & Howell part number: Spring Belt Part # 10089 metal spring: 14 5/8" long & 5/32" diam. overall looped hook at each end. The size of the 2 looped hooks DO NOT figure into the length of the belt! (B&H edict) The 1st generation of the 400 ft mag used a "Loading clip" to hold the light valves in the magazine open when the small plunger was pushed in (red arrow). This makes it easy to push the film through the magazine openings. A 'Shepards Hook' it was called Worked like this (clever idea)... Well, those were easily lost and you never see them on eBay. One should be included with each 400 ft mag! (I only have 2 of them) In the later years B&H came up with a smaller device to accomplish opening the valves, the 'Magazine Loading Key' This was screwed on before loading film in the dark. It opened the light valves. The arrow points to the plunger. It is screwed on the magazine mounting screw for the camera. After you loaded your film in the dark, and while in the dark, you would take this key off to close the valves so your film wouldn't be exposed while mounting the mag to the camera. Then you would put this key in a very safe place so it won't get lost. lol When the mag was mounted on the camera and the film threaded, you put the lid or door on the camera, the door would push against the lever in the back by the opening in the body, and then open the valve so the film can flow freely. Red arrow. If you want to run the camera and visually see how the film is moving, you have to remember to push that lever to open the valves so the film won't jam. A lot of juggling!! What the magazine throat looks like: Figure it out? Have you checked this system to make sure the film is flowing easily from the magazine? Charlie -

70HR/KRM info, instruction manual, tips

Charlie Peich replied to Philip Forrest's topic in Bell + Howell

Contact this guy on eBay (yes I know, eBay) I bought Eyemo take-up springs from him before. He has the lists and knows the size of the spring you need. https://www.ebay.com/itm/350166571709?hash=item51878ddabd:g:9UkAAOSw~~Rf4PY5 Fast service! Charlie -

New IMAX Film Cameras in Development

Charlie Peich replied to Tim Tyler's topic in Cinematography News

Hello John! The proper name is 'Geoff' Williamson. You might try googling again with that combination. Mr. Williamson released a Wilcam W-4 in the 1st part of 1983. I attached a short write-up about it that was published in a popular industry magazine...... Geoff Williamson made several other cameras.... Super 8 single system mag sound for news filming, 16mm single system mag sound for news filming, 2 - 35mm quiet production cameras, a 35mm 300fps camera and this 65mm camera. Charlie -

Greetings Duncan! "I just know it's going to be something stupid, like with "MOS Camera"... Close.... 'DOM' is the 1st 3 letters for......... are you ready for this? .... 'DOMestic' Noun: something produced or manufactured in one's own county. Arri USA used 'DOM' exclusively to identify any Arri camera equipment that was designed and manufactured in the USA, not at the main factory in Germany. This was when Arri Germany and Arri USA were separate organisations. The most popular item was the DOM Animation/Time Lapse motor for the 16S and 16M cameras. Way back in the mid '50s, there was an interest in 'single framing' with these 16mm cameras. The cameras were not really designed for single frame operation, but Arri offered this 'lightweight' motor in April 1956... Meanwhile, back in Germany Arri factory made 'The Single Frame Gear'. This unit fit in between the camera and the drive motor. Not very popular in the U.S., in my opinion. So , Arri USA continued making and refining the DOM unit and ended with this version in the late '60s, early '70s. You still had to get a capping shutter which came from Germany. Hope that answers your question... Charlie

-

Alan Gordon gear device for Arri 16 - might be 716GE-5 ?

Charlie Peich replied to Duncan Brown's topic in ARRI

Oooops, forgot to add the pic of the NCE motor adaptors........ -

Alan Gordon gear device for Arri 16 - might be 716GE-5 ?

Charlie Peich replied to Duncan Brown's topic in ARRI

Greetings Duncan! Your mystery part for the Arri 16 ST (or M) is the 'camera adaptor' for an NCE Animation Motor Drive System for 16mm or 35mm cameras. This single frame motor drive was probably made by Gordon Enterprises. One would purchase the Control Box and motor, then add the appropriatecamera adaptor for the camera or cameras they wanted to use it on. You would still need a 'capping shutter' to use it with the Arri cameras, as those cameras were not really designed to be used for single framing. They could fog the film from light entering the lens when the film was at rest. The controller has provisions for 'synchronized shutter openings' or to use the 'capping shutter'. I've never seen this set up, not even on eBay. Back in 1983, the NCE III Controller and Motor would have set you back $1650, then you add the cost of the camera adaptor. Also, the motor was 120 volts. You would need a long extension cord or a generator to use it in the desert for time-lapse with an intervalometer. Nice looking piece of Arri equipment however! Charlie -

Bell and Howell 16mm Filmo questions

Charlie Peich replied to Patrick Cooper's topic in Bell + Howell

Looks like someone made a lens support.... .https://www.ebay.com/itm/185017981152?hash=item2b13ee58e0:g:cuQAAOSwrnRhHpJU -

Mystery wire on an Arri 16 S/B power cord. Any Ideas?

Charlie Peich replied to Francis Kuhn's topic in ARRI

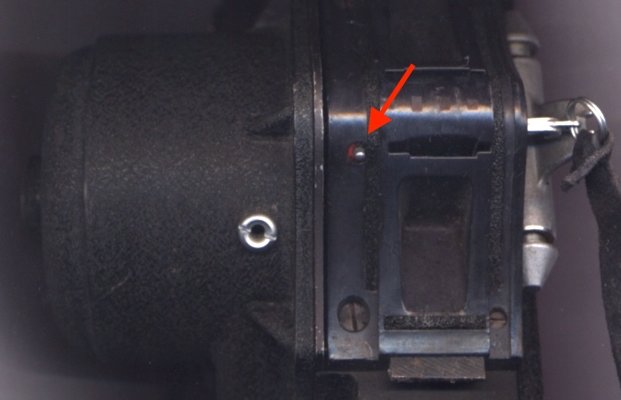

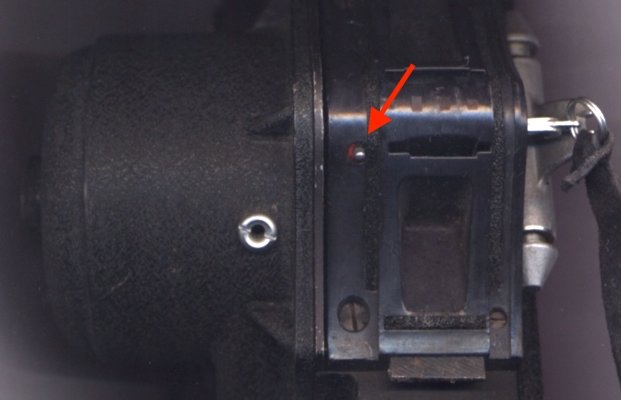

Greetings Tim and Fran! The little wire on the power cord is indeed a grounding wire. It is used to ground the torque motor on the 200ft or 400ft magazines. Arri literature said: "As the magazine is attached to the camera, electrical contact is automatically made." Well, yes and possibly no. In the pic below, the torque motor is attached to the magazine. The torque motor is now grounded to the magazine. When the magazine is attached to the camera body, the magazine is now grounded to the camera body completing the electrical circuit for the little torque motor. The red arrow points to the contact pin on the magazine for the positive 8 or 12 volts from the camera. The exposed metal of the magazine is supposed to ground the magazine to the camera body.... However, possibly in the early days of the magazines, the electrical ground, for some reason, didn't make a complete circuit through the camera. It could be corrosion that caused resistance in the ground circuit reducing the voltage. Arri backed up this possible (sometimes unpredictable) condition by having a little ground wire that plugged into the small, silver socket (see above pic) underneath the motor and then to the neg side of the power cable. This provided a good positive ground for the torque motor. When I 1st started shooting with the 16s and mags, I always used the wire. But after a while I stopped that annoyance and just mounted the mag. I never had any problems. The little grounding wire I used finally disappeared (I do have one left .... just in case). You just forgot about this Tim! lol Charlie -

Hello John! Take a look at this site for the 'Museum of Magnetic Sound Recording'. It states that the Webster Wire Recorder was made after the war. A link to the Wire recorders: https://museumofmagneticsoundrecording.org/Wire.html Cheers! Charlie

-

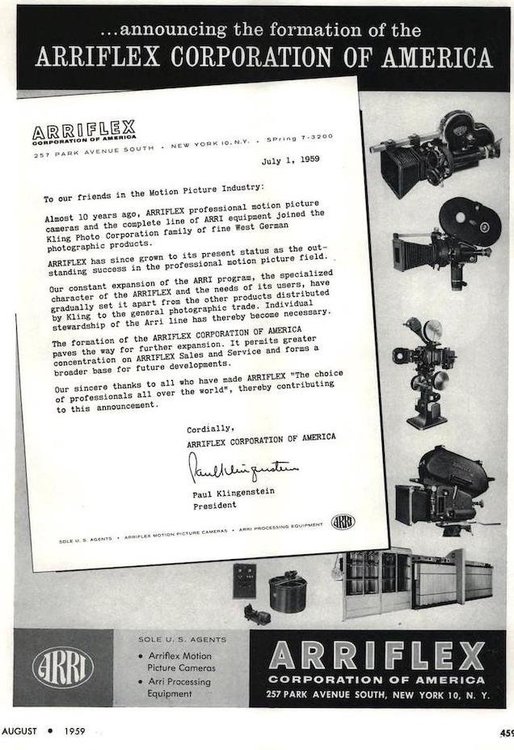

Greetings Dom! I thought you would find this Arri advert from 1959 informative..... Arriflex Corporation of America made many Arri items for the American market. They called them 'DOM' for 'Domestic'. Charlie

-

Minolta Spot Meter M (Can't find 1/50s mode)

Charlie Peich replied to Hugo Knapp's topic in Accessories (Deprecated SubForum)

Greetings Hugo! Thank you for posting the pic of your Minolta M and the link to an instruction manual for a Minolta M (n). This helps me solve the confusion of the 6 volt battery, the meter lock switch and the Cine speed of 1/50 at the end of the shutter speed scale. Minolta came out with the model M (n), or version 1 that still had a 6 volt battery. I was not aware of of this version of the M. When I acquired my M, it was the 2nd upgraded version of the M, and had the 1.5 volt AA battery. From your pic, this is the version/model you have. I've copied a couple of pages from my Minolta M instruction manual. Compare these to the same pages in the on-line manual for the Minolta M (n) that you posted a link for....... (the page numbers on my pages match the same pages for the M (n) pages) On page 4 of the manual for the 2nd version of the M (the ones we have), you'll see it does not mention the Cine speed of 1/50 at all. Then look at the on-line manual for page 4. The 'Meter Lock' switch was nothing more than an on/off switch as is on our meters. The Minolta F reinstated that Cine function, apparently enough people complained. So why did Minolta make those changes to the Minolta M meter?? Read the very last sentence on page 19 of the English language manual or the on-line manual you provided. Charlie -

Minolta Spot Meter M (Can't find 1/50s mode)

Charlie Peich replied to Hugo Knapp's topic in Accessories (Deprecated SubForum)

Hugo...... Does your meter look like the one in the photo from a catalog? It does say the Auto Meter takes a 6volt battery. Also, it says there were 2 models, analog and digital. The spot meter I had before the Minoltas was a Pentax analog meter. Could you post a pic of your meter?? Charlie -

Minolta Spot Meter M (Can't find 1/50s mode)

Charlie Peich replied to Hugo Knapp's topic in Accessories (Deprecated SubForum)

Hello Hugo and Dirk! Hugo, you said: "On my Minolta M Spotmeter when I get to 30m and press the decrease key again, nothing happens..". That's correct, nothing will happen on the Minolta M meter. The model M was the 1st version, and in my opinion the better of the 2 models (the F being the 2nd) for Cine work at the time it was introduced. Yet, the model F was faster to make settings adjustments and figuring the Cine measurements. (seems the model F went to 11) The model M does take one AA battery, 1.5 volt. Here's how to set the meter for Cine measurement... It turned out that the model M was better at reading discontinuous light than the improved model F. So, for me, the model M is more accurate when reading the old TV monitors, projected film on screens and subjects under HMI lights. I used both models. Another thing to think about when using your spotmeter on sets with multiple light sources, you need to shade the meter's lens from stray light. As these meters became popular, small cottage industries popped up making nice slip-on aluminum snoots for the meter...... One had to have a snoot to look cool among the crew members. Charlie -

Your motor is the basic Arri 16 S / 16 M Governor Controlled motor that was modified to output a 1 volt sync pulse/signal that was fed to a 1/4 inch synchronous tape recorder. One would plug the sync cable (umbilical cord, as it was called) from the recorder into the single pin RCA jack located on the back of the motor next to the knurled turning knob. Any minor speed variations or fluctuations of the camera would be recorded on the ¼ inch tape. With this motor you could then shoot lip-sync sound with your noisy Arri 16 S (with additional sound coming from the 400 ft torque motor) or M camera (well, maybe the camera was in that user friendly ‘blimp’). You wouldn’t need an A.C. power supply or the Arri a.c. sync motor for sync filming. The camera was driven by batteries and same for the recorder. “Governor controlled motor for 8 V battery operation with fixed camera speed of 24 (Cat. No. 1161) or 25 frames per second (Cat. No. 1162). This speed is automatically maintained and cannot be changed. The speed required should be stated when placing an order. Other speeds can be adjusted on request. This motor is designed for forward drive only, and a knurled knob for turning the camera mechanism by hand is also provided.” Most likely the speed of your motor is 24 fps. You can always check the speed of the motor on the camera with a strobe light. The motor used for this modification was the early Arri Governor Controlled motor. This was the one without the transistor attached to it. I would guess your motor is from the early to late 1960s. The sync pulse modification did not change the operation of the motor. So, now you have a constant speed motor (24 fps) for your 16 S camera. This motor was modified by Magnetic Sales Corp, an equipment division of Loren Ryder’s ‘Ryder Sound Services, Inc’ at the same address. Loren Ryder started his business in 1948. He was an early pioneer in magnetic sound recording for Motion Pictures, initially working for Paramount. He became a leader in the industry for portable magnetic recording on location. https://en.wikipedia.org/wiki/Loren_L._Ryder There is a nice article about him in the May 1973 American Cinematographer.

-

"Your camera and magazine might need to be connected by a ground wire." Chris, I agree with Jean-Louis's above statement. According to Arri back in the day, the torque motor was grounded to the magazine when locked into place on the mag. When the magazine was attached to the camera, the magazine was supposed to be grounded to the camera. But, back then there must have been occasional problems with grounding the torque motor, so Arri came up with a sure fire solution, ground the torque motor directly to the ground on the battery. This was accomplished with a 'ground wire' as Jean-Louis recommended. When you purchased a 16 S power cable from Arri, it came with a grounding wire for the torque motor. One end of the grounding jumper cable was plugged into the ground side the power cable, and the other end was plugged into the torque motor via the silver receptacle shown in the pic below. 400 ft & 200 ft torque motors have the same grounding connection. The red arrow points to the positive power pin in the magazine that makes contact with the camera. When the cameras were newer, it was rare to use the jumper cable (my experience). I used 4 torque motors and never had problems, or needed to use the cable. Most users removed that little cable from the power cord and set it aside. If you were just using 100ft loads, you didn't need it. Then those little cables would eventually disappear. I've seldom seen them in 16 S kits for sale. Arri listed the ground cable in a 1962 price list: "Special Ground Connection Cable (Replacement); goes from main Cable to Torque Motor". It was still listed in a price list as late as 11/1980. I don't have the separate instruction sheet for the 400ft mag and torque motor. Very little was said by Arri about this ground cable. There are no ad pictures that I've seen showing this little cable in use. Applying 8.4 volts to a torque motor that was modified for 12 volts would just make the torque motor run slower. If the circuit supplying power to the torque motor, and then to ground, is complete, it would still run.